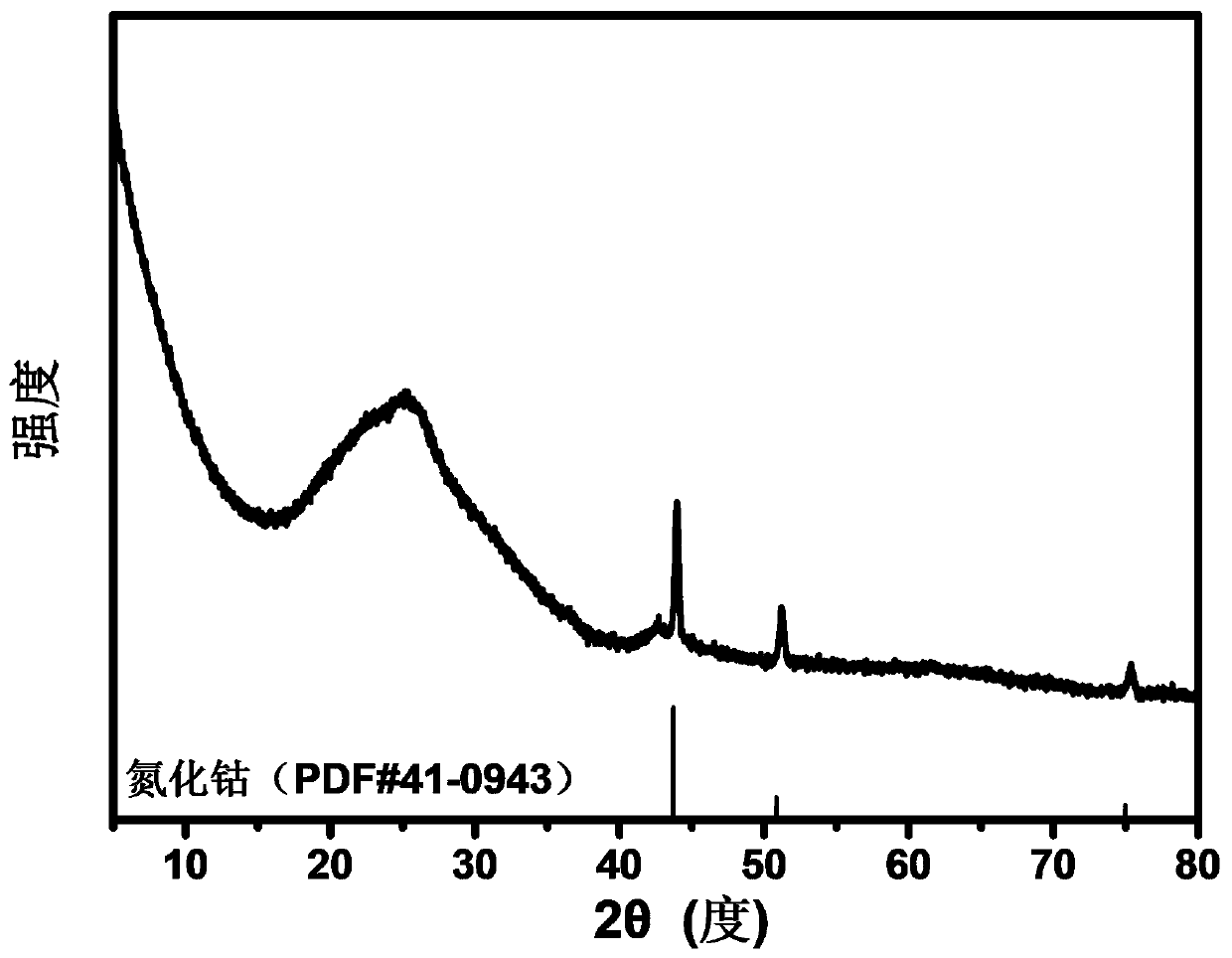

Preparation method of positive material for cobalt nitride/porous carbon plate/carbon cloth self-supported lithium-sulfur battery

A lithium-sulfur battery and cathode material technology, applied in the manufacture of battery electrodes, lithium batteries, electrolyte batteries, etc., to achieve the effects of dissolution and shuttling inhibition, wide application prospects, and developed pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First, clean the carbon cloth with deionized water, ultrasonically clean it with acetone and ethanol, then put it in a 60°C oven for drying, oxidize it in concentrated nitric acid at 90°C for 6 hours, and wash it with deionized water until pH=7, 60 Drying at ℃; obtain carbon with cobalt-based metal-organic framework growing on the surface; figure 1 are digital photographs and scanning electron microscope (SEM) photographs of the material;

[0030] (2) Dissolve cobalt nitrate hexahydrate and 2-methylimidazole in water respectively, and make the molar ratio of cobalt nitrate and 2-methylimidazole 1:4, the concentration of 2-methylimidazole is 0.4M, and (1 ) was added to the oxidized carbon cloth obtained in cobalt nitrate aqueous solution, and then the above-mentioned 2-methylimidazole solution was added, shaken for 3 minutes, and then left to react for 4 hours. After the reaction, the carbon cloth was alternately rinsed with deionized water and ethanol, and dried at...

Embodiment 2

[0038] (1) First, clean the carbon cloth with deionized water, ultrasonic cleaning with acetone and ethanol, and then dry it in a 60°C oven. Put the dried carbon cloth in concentrated sulfuric acid, oxidize it at 60°C for 3 hours, and deionize it. Wash with water to pH=7, dry at 60°C;

[0039] (2) Prepare methanol solutions of cobalt nitrate hexahydrate and terephthalic acid respectively, so that the molar ratio of cobalt nitrate and terephthalic acid is 1:10, and the concentration of terephthalic acid is 0.5M. Add the oxidized carbon cloth to the cobalt nitrate solution, then add the prepared terephthalic acid solution, shake it for 3 minutes and let it stand for 12 hours to react; wash the carbon cloth alternately with deionized water and ethanol, and dry it in an oven at 60°C to obtain a surface Carbon cloth for growing cobalt-based metal-organic framework materials;

[0040] (3) Heat the material obtained in (2) to 500°C in a nitrogen atmosphere at a heating rate of 4°C / m...

Embodiment 3

[0044] (1) First, clean the carbon cloth with deionized water, ultrasonic cleaning with acetone and ethanol, and then dry it in a 60°C oven; put the dried carbon cloth in nitrous acid, and oxidize it at 120°C for 3 hours; deionized water Wash until pH = 7, and dry in an oven at 60°C;

[0045] (2) Prepare ethanol solutions of cobalt nitrate hexahydrate and 2-methylimidazole respectively, and make the molar ratio of cobalt nitrate and 2-methylimidazole 1:7, and the concentration of 2-methylimidazole is 0.1M, and (1 ) was added to the cobalt nitrate solution, and then the prepared 2-methylimidazole solution was added, shaken for 3 minutes and left to react for 24 hours; after the reaction, the carbon cloth was washed alternately with deionized water and ethanol, Dry in an oven at 60°C;

[0046] (3) Heat the material obtained in (2) to 600°C in a nitrogen atmosphere at a heating rate of 2°C / min and keep it warm for 4 hours; then oxidize the material at 300°C in an air atmosphere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com