Additive for improving mechanical properties of a silicon-manganese alloy

A silicon-manganese alloy and additive technology, which is applied in the field of silicon-manganese alloy preparation, can solve problems such as poor melt quality, substandard alloy performance, and high cost, and achieve the effects of increasing resistance to melting temperature, improving mechanical properties, and enhancing hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

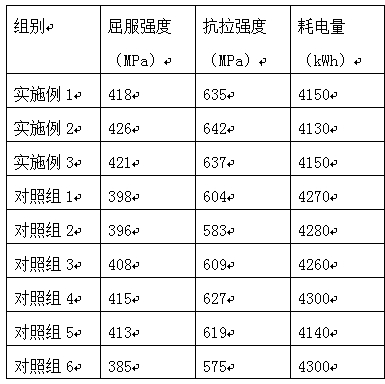

Examples

Embodiment 1

[0015] An additive for improving the mechanical properties of silicon-manganese alloys, comprising the following raw materials in parts by weight: 65 parts of silicon powder, 40 parts of manganese powder, 2 parts of aluminum powder, 4 parts of titanium dioxide composite material, 0.7 part of surfactant, polyacrylonitrile-based carbon fiber 2 parts, 0.25 parts of isobutyl α-cyanoacryloyl glycolate, 1 part of flux, 2.5 parts of phosphoramidate containing heterocyclic rings, 0.4 parts of manganese hydroxide, 0.3 parts of guanidine nitrate;

[0016] The preparation method of the titanium dioxide composite material is to mix the nano-titanium dioxide powder with distilled water to make a mixed solution of 50 mg / 100mL, then add fluorite powder equivalent to 9 times the weight of the nano-titanium dioxide powder, and treat it at an ultrasonic frequency of 24kHz for 5 Minutes, after completion, it is dried to constant weight at a temperature of 90°C, and then roasted at a temperature o...

Embodiment 2

[0024] An additive for improving the mechanical properties of silicon-manganese alloys, comprising the following raw materials in parts by weight: 60 parts of silicon powder, 45 parts of manganese powder, 1.8 parts of aluminum powder, 5 parts of titanium dioxide composite material, 0.6 part of surfactant, polyacrylonitrile-based carbon fiber 1 part, 0.4 part of isobutyl α-cyanoacryloyl glycolate, 1.2 parts of flux, 2.2 parts of phosphoramidate containing heterocycle, 0.6 part of manganese hydroxide, 0.35 part of guanidine nitrate;

[0025] The preparation method of the titanium dioxide composite material is to mix the nano-titanium dioxide powder with distilled water to make a mixed solution of 60mg / 100mL, then add fluorite powder equivalent to 10 times the weight of the nano-titanium dioxide powder, and treat it under the condition of an ultrasonic frequency of 26kHz for 4 minutes, after completion, it is dried to a constant weight at a temperature of 95°C, and then roasted at...

Embodiment 3

[0033] An additive for improving the mechanical properties of silicon-manganese alloys, comprising the following raw materials in parts by weight: 70 parts of silicon powder, 35 parts of manganese powder, 2.2 parts of aluminum powder, 3 parts of titanium dioxide composite material, 0.8 part of surfactant, polyacrylonitrile-based carbon fiber 3 parts, 0.1 part of isobutyl α-cyanoacryloyl glycolate, 0.8 part of flux, 2.8 parts of phosphoramidate containing heterocycle, 0.2 part of manganese hydroxide, 0.25 part of guanidine nitrate;

[0034] The preparation method of the titanium dioxide composite material is to mix the nano-titanium dioxide powder with distilled water to make a mixed solution of 40 mg / 100mL, then add fluorite powder equivalent to 8 times the weight of the nano-titanium dioxide powder, and treat it at an ultrasonic frequency of 22kHz for 6 minutes, after completion, it is dried to constant weight at a temperature of 85°C, and then roasted at a temperature of 450°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com