Method for preparing chitosan oligosaccharide by using lipase

A lipase and chitosan oligosaccharide technology, which is applied in the field of preparation of chitosan oligosaccharides by lipase, can solve the problems of long reaction time, color impact of degradation products, and many types of enzymes, etc., to achieve uniform color and good product quality , The effect of short enzymatic hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

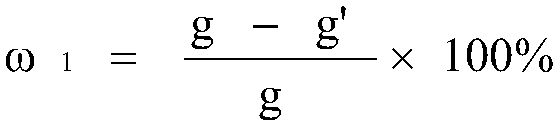

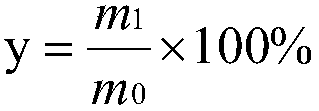

[0028] Embodiment 1, the present invention utilizes lipase to prepare the method for chitosan oligosaccharide

[0029] S1 dissolves: chitosan is dissolved in the acetic acid-sodium acetate buffer solution of pH value 4.0 and adds 0.1% sucrose fatty acid ester (HLB value 10) of chitosan weight, is made into the chitosan that mass concentration is 1.0% sugar solution;

[0030] S2 lipase hydrolysis: add a lipase solution with a concentration of 0.5% to the chitosan solution obtained in step S1, so that the mass ratio of the enzyme to the bottom is 20%, and place it in a constant temperature water bath at 40°C for 0.5h to obtain the enzymolysis solution, take it out and boil it in a water bath 10 minutes for inactivation, cooled to room temperature;

[0031] S3 adjusting pH and dialysis: adding dropwise NaOH solution with a mass concentration of 5% to the enzymolysis solution obtained in step S2 to adjust the pH value to 7.0-8.0, so that water-insoluble chitosan is precipitated, ...

Embodiment 2

[0034] Embodiment 2, the present invention utilizes lipase to prepare the method for chitosan oligosaccharide

[0035] S1 dissolves: chitosan is dissolved in the acetic acid-sodium acetate buffer solution of pH value 4.5 and adds 0.4% sucrose fatty acid ester (HLB value 12) of chitosan weight, is made into the chitosan that mass concentration is 1.7% sugar solution;

[0036] S2 lipase hydrolysis: add the lipase liquid that concentration is 0.5% to the chitosan solution gained in step S1, make the mass ratio of enzyme bottom be 22%, 45 ℃ constant temperature water baths 1h, obtain enzymolysis liquid, after taking out, boiling water bath 10 Minutes for inactivation, cooled to room temperature;

[0037]S3 adjusts pH and dialysis: in the enzymolysis solution gained in step S2, add dropwise the NaOH solution that mass concentration is 5% to adjust pH to 7.0~8.0, make water-insoluble chitosan separate out, take filtrate after filtering and discard filter residue, will The filtrate...

Embodiment 3

[0040] Embodiment 3, the present invention utilizes lipase to prepare the method for chitosan oligosaccharide

[0041] S1 dissolves: chitosan is dissolved in the acetic acid-sodium acetate buffer solution of pH value 5.0 and adds the sucrose fatty acid ester (HLB value 13) of 0.5% chitosan weight, is made into the chitosan that mass concentration is 2.0% sugar solution;

[0042] S2 lipase hydrolysis: add lipase liquid with a concentration of 0.5% to the chitosan solution obtained in step S1, so that the mass ratio of the enzyme to the bottom is 30%, 50 ℃ constant temperature water bath for 1.5h, to obtain the enzymolysis solution, take it out and boil it in water bath 10 minutes for inactivation, cooled to room temperature;

[0043] S3 adjusts pH and dialyzes: in the enzymolysis solution gained in step S2, add dropwise the solution that mass concentration is 5% NaOH to adjust pH to 7.0~8.0, make water-insoluble chitosan separate out, take filtrate after filtering and discard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com