Preparation method and application of a metal-organic polymer-loaded au-doped quantum dot composite material

A metal-organic and composite material technology, applied in the fields of nanomaterials, metal-organic complexes and electrochemical detection, can solve problems such as affecting people's lives, weak environmental awareness, groundwater, rivers, lakes and sea pollution, etc. Short, chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 A preparation method of a metal-organic polymer-supported Au-doped quantum dot composite material

[0044] (1) Preparation of the adamantane-based ligand ADM-BP

[0045]Blend 1.8771g amantadine hydrochloride, 2g potassium carbonate and 60mL acetonitrile, add 1.3203g 2,6-bis(chloromethyl)pyridine, stir vigorously; heat to 80°C, react for 24 hours, then cool to room temperature , filtered, washed with acetonitrile and water successively, and dried at 60°C; the obtained solid was dissolved in 20 mL of dichloromethane, and then 15 mL of water was added, shaken sufficiently, allowed to stand, and separated; the obtained organic layer was dried by adding sodium sulfate, Distillation, remove solvent, obtain adamantane amino ligand ADM-BP powder, productive rate is 70%;

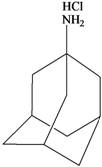

[0046] Described amantadine hydrochloride, structural formula is as follows:

[0047]

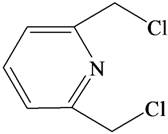

[0048] Described 2,6-bis(chloromethyl)pyridine, structural formula is as follows:

[0049]

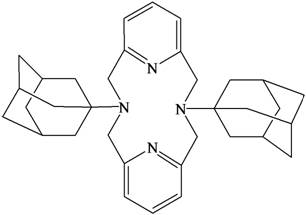

[0050] Th...

Embodiment 2

[0064] Example 2 Preparation method of a metal-organic polymer-supported Au-doped quantum dot composite material

[0065] (1) Preparation of the adamantane-based ligand ADM-BP

[0066] Blend 2.3464g amantadine hydrochloride, 2.5g potassium carbonate and 70 mL acetonitrile, add 1.7604g 2,6-bis(chloromethyl)pyridine, stir vigorously; heat to 80°C, react for 24 hours, then cool to room temperature, filtered, washed with acetonitrile and water successively, and dried at 60°C; dissolved the obtained solid in 25mL of dichloromethane, then added 15mL of water, shaken fully, stood still, and separated; added sodium sulfate to the obtained organic layer Drying, distillation, removal of solvent, the adamantane amino ligand ADM-BP powder is obtained, and the yield is 75%;

[0067] Described amantadine hydrochloride, structural formula is as follows:

[0068]

[0069] Described 2,6-bis(chloromethyl)pyridine, structural formula is as follows:

[0070]

[0071] The structural formu...

Embodiment 3

[0085] Example 3 Preparation method of a metal-organic polymer-supported Au-doped quantum dot composite material

[0086] (1) Preparation of the adamantane-based ligand ADM-BP

[0087] Blend 2.8157g amantadine hydrochloride, 3g potassium carbonate and 80mL acetonitrile, add 2.2005g 2,6-bis(chloromethyl)pyridine, stir vigorously; heat to 80°C, react for 24 hours, then cool to room temperature , filtered, washed with acetonitrile and water successively, and dried at 60°C; the obtained solid was dissolved in 30 mL of dichloromethane, and then 15 mL of water was added, shaken sufficiently, allowed to stand, and separated; the obtained organic layer was dried by adding sodium sulfate, Distillation, remove solvent, obtain adamantyl amino ligand ADM-BP powder, productive rate is 72%;

[0088] Described amantadine hydrochloride, structural formula is as follows:

[0089]

[0090] Described 2,6-bis(chloromethyl)pyridine, structural formula is as follows:

[0091]

[0092] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com