Single-silicon nanowire fluorescent chemical sensor for detecting hypochlorite and preparation method and application of single-silicon nanowire fluorescent chemical sensor

A technology of chemical sensors and silicon nanowires, applied in the field of fluorescent chemical sensors, can solve problems such as inaccurate understanding and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

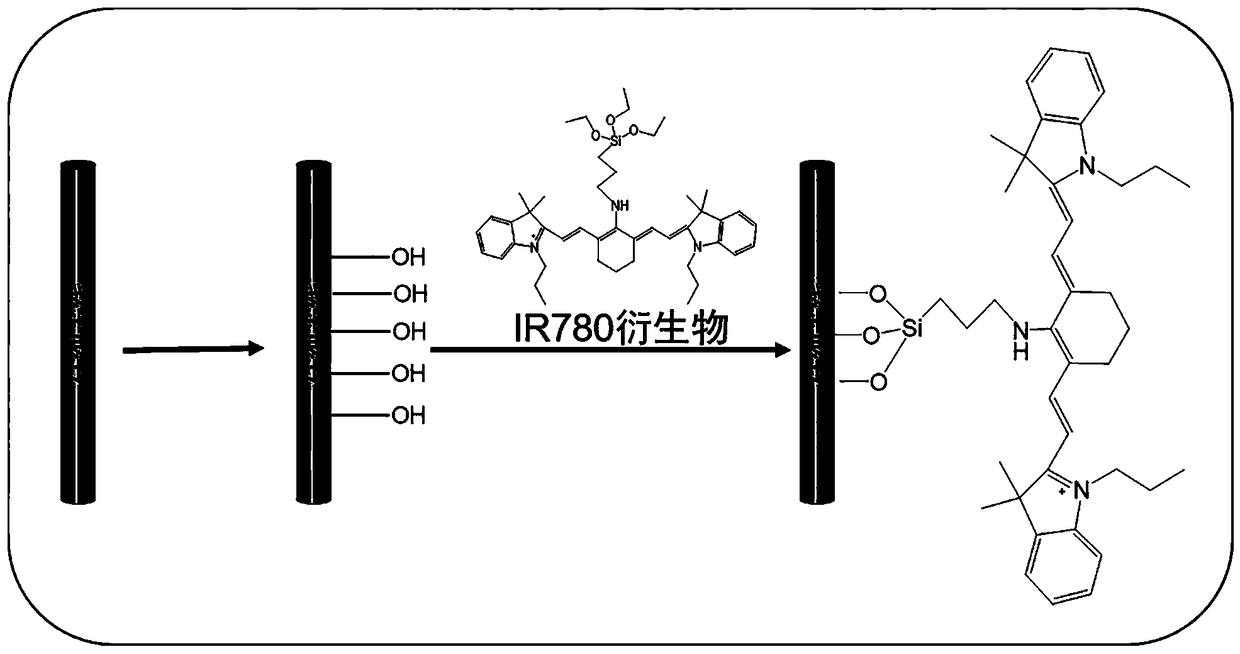

[0045] In a second aspect, the present invention provides a method for preparing a single silicon nanowire fluorescent chemical sensor for detecting hypochlorite, comprising the following steps:

[0046] 1) Preparation of silicon nanowire arrays with Si-OH bonds on the surface: boil the silicon nanowire arrays in a mixed solution of concentrated sulfuric acid and 30% hydrogen peroxide solution with a volume ratio of 2:1 to 4:1 at 90°C for 45min to 1.5h, cool to room temperature, wash with water until neutral; soak in a mixed solution of water, 30% hydrogen peroxide solution and ammonia water with a volume ratio of 3:1:1~6:1:1 for 2.5~4h, wash with water until neutral , dried in vacuum to obtain a silicon nanowire array with Si-OH bonds on the surface;

[0047] 2) Synthesis of IR780 derivatives: Add IR780 and 3-aminopropyltriethoxysilane to an organic solvent, heat to 120°C under the protection of an inert gas, react at a constant temperature for 30 minutes, evaporate the organ...

Embodiment 1

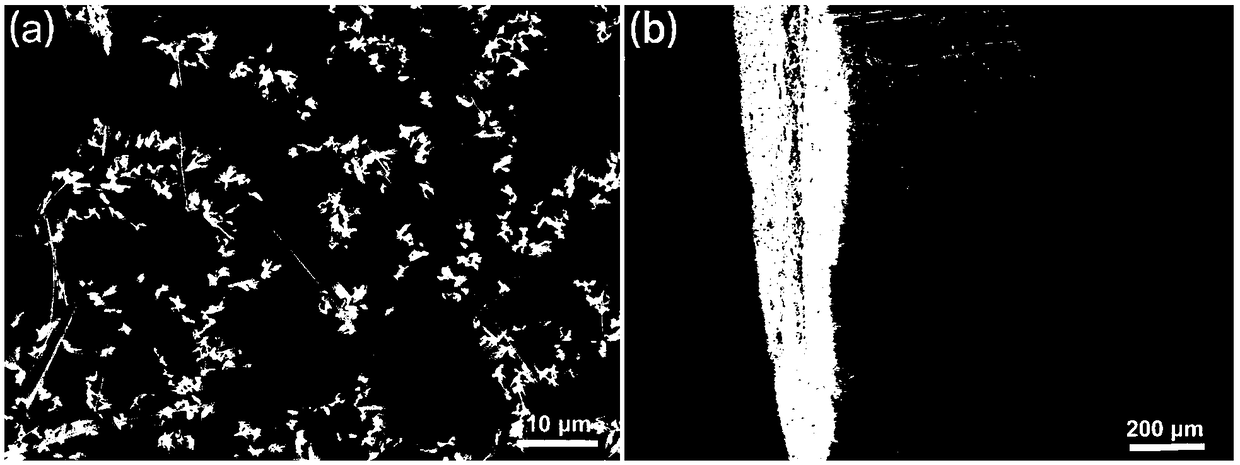

[0066] 1) Take n(100) silicon wafers of 0.5cm×3cm, and ultrasonically clean them with acetone, ethanol, and distilled water for 10 minutes respectively, take out the cleaned silicon wafers, and place them in AgNO with a concentration of 5mmol / L. 3 and 4.8mol / L HF mixed aqueous solution, after soaking for 8min, take it out and put it into 200mL containing 4.8mol / L HF and 0.2mol / L H 2 o 2In the mixed aqueous solution, the system was kept warm in a water bath at 50°C; after 2 hours, the silicon chip was taken out and placed in a mixture containing 15mL of concentrated hydrochloric acid (36% in mass concentration) and 5mL of concentrated nitric acid (65% in mass concentration), and soaked for 1h Finally, the silicon wafer was taken out, rinsed with distilled water, and then dried naturally to obtain a silicon nanowire array composed of silicon nanowires. The silicon nanowires in the silicon nanowire array have a diameter of 100-400nm and a length of about 200μm. The SEM photo of ...

Embodiment 2

[0072] 1) Take n(100) silicon wafers of 0.5cm×3cm, and ultrasonically clean them with acetone, ethanol, and distilled water for 30 minutes, and place the cleaned silicon wafers in AgNO with a concentration of 3mmol / L. 3 Soak in a mixed aqueous solution of 2mol / L HF and 2mol / L HF for 10min, take out the silicon chip and immerse it in 200mL containing 2mol / L HF and 0.05mol / L H 2 o 2 In the mixed aqueous solution, the system was kept warm in a water bath with a temperature of 60°C. After 150 minutes, the silicon chip was taken out and put into 15 mL of concentrated hydrochloric acid (36% in mass concentration):concentrated nitric acid (65% in mass concentration) with a volume ratio of 3: 1 in the mixed solution, soaked for 0.5h, took out the silicon chip, rinsed with distilled water and dried naturally to obtain a silicon nanowire array composed of silicon nanowires;

[0073] 2) At room temperature, cook the silicon nanowire array in 10 mL of concentrated sulfuric acid: 30% hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com