Waterproof paint, and preparation method thereof

A technology for waterproof coatings and raw materials, applied in the field of coatings, can solve problems affecting appearance and waterproof performance, dark bubbles in waterproof coating films, aging defects, etc., to improve activity and storage stability, improve plasticization, and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

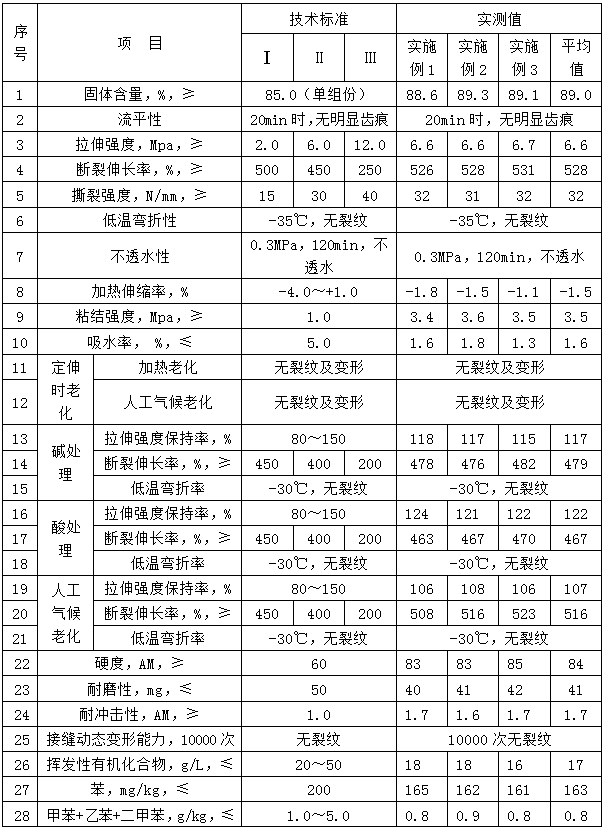

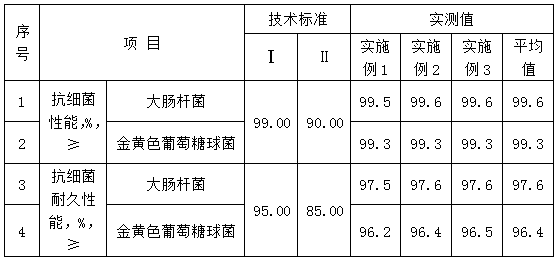

Examples

Embodiment 1

[0023] A waterproof coating, comprising the following raw materials in parts by weight: 35 parts of modified polyether polyols, 15 parts of aluminum silicate powder, 8 parts of benzoyl peroxide, 5 parts of phosphoric acid, and 5 parts of diphenylmethane diisocyanate , 8 parts of dioctyl phthalate, 1 part of polyether modified polysiloxane defoamer, 8 parts of nano titanium dioxide, 3 parts of hydroquinone, 5 parts of UV-531, 1,2-benzo 1 part of isothiazolin-3-one, 3 parts of 4-hydroxybenzenesulfonic acid.

[0024] The preparation method of the modified polyether polyol: add propylene oxide and half the amount of calcium hydride into the reaction kettle, 40°C, pressure less than 1MPa, constant temperature reaction for 1.5h; add ethylene oxide and sodium hydroxide under reduced pressure And the other half of calcium hydride, 80 ℃, pressure less than 1.5 MPa, constant temperature reaction for 5 hours; decompression and cooling, add boric acid, 100 ℃, pressure less than 1 MPa, rea...

Embodiment 2

[0031] A waterproof coating, comprising the following raw materials in parts by weight: 50 parts of modified polyether polyols, 8 parts of aluminum silicate powder, 12 parts of benzoyl peroxide, 2 parts of phosphoric acid, and 8 parts of diphenylmethane diisocyanate , 5 parts of dioctyl phthalate, 3 parts of polyether modified polysiloxane defoamer, 5 parts of nano titanium dioxide, 5 parts of hydroquinone, 2 parts of UV-531, 1,2-benzo 3 parts of isothiazolin-3-one, 1 part of 4-hydroxybenzenesulfonic acid.

[0032]The preparation method of the modified polyether polyol: add propylene oxide and half the amount of calcium hydride into the reaction kettle, 60 ℃, pressure less than 1MPa, constant temperature reaction for 1h; add ethylene oxide, sodium hydroxide and The other half of calcium hydride, 100 ℃, pressure less than 1.5 MPa, constant temperature reaction for 3 hours; decompression and cooling, add boric acid, 110 ℃, pressure less than 1 MPa, reaction 3 hours, in which pro...

Embodiment 3

[0039] A waterproof coating, comprising the following raw materials in parts by weight: 46 parts of modified polyether polyols, 13 parts of aluminum silicate powder, 10 parts of benzoyl peroxide, 4 parts of phosphoric acid, 6 parts of diphenylmethane diisocyanate , 7 parts of dioctyl phthalate, 1.5 parts of polyether modified polysiloxane defoamer, 6 parts of nano titanium dioxide, 4 parts of hydroquinone, 4 parts of UV-531, 1,2-benzo 1.5 parts of isothiazolin-3-one, 2 parts of 4-hydroxybenzenesulfonic acid.

[0040] The preparation method of the modified polyether polyol: add propylene oxide and half the amount of calcium hydride into the reaction kettle, 50°C, pressure less than 1MPa, constant temperature reaction for 1.5h; add ethylene oxide and sodium hydroxide under reduced pressure And the other half of calcium hydride, 90 ℃, pressure less than 1.5 MPa, constant temperature reaction for 4 hours; decompression and cooling, add boric acid, 100 ℃, pressure less than 1 MPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com