A method for preparing a low-heat-conductivity C/C-PI composite material

A technology of C-PI and composite materials, which is applied in the field of preparation of C/C composite materials, can solve the problems of difficult batch production, high cost, solvent toxicity, etc., and achieve good heat resistance, short preparation cycle and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

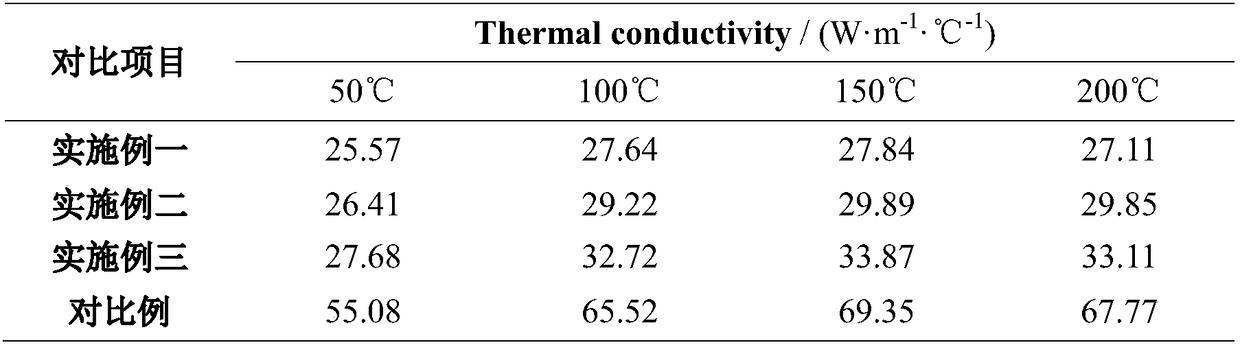

Embodiment 1

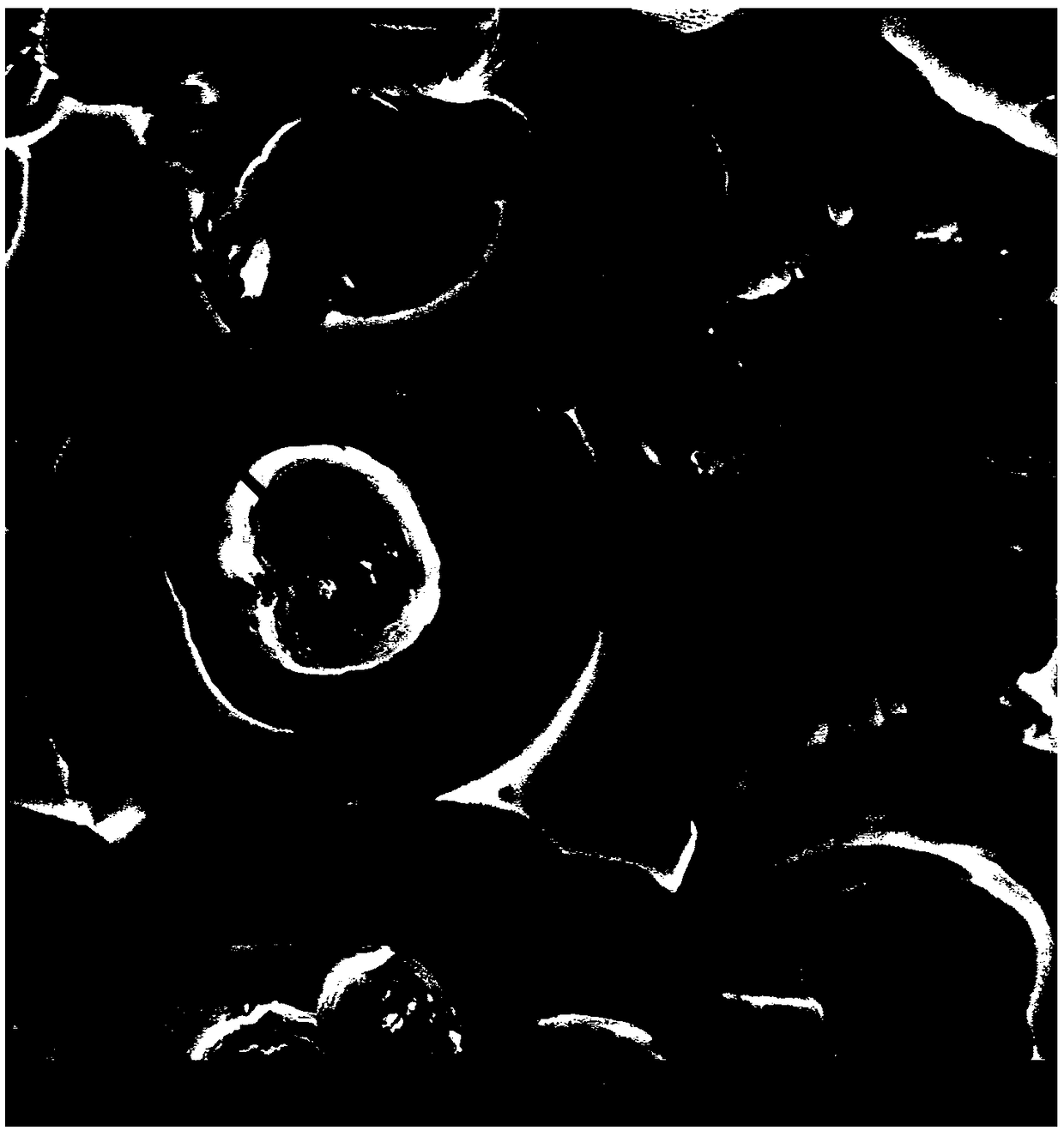

[0020] In this example, participating in figure 1 , a preparation method of low thermal conductivity C / C-PI composite material, comprising the steps of:

[0021] a. Carbonize the polyacrylonitrile pre-oxidized felt at 950°C;

[0022] b. Using propylene as a carbon source, deposit pyrolytic carbon on the polyacrylonitrile pre-oxygenated felt substrate after the treatment in step a by chemical vapor infiltration (CVI), control the deposition temperature to be 950°C, and then undergo a high temperature of 2300°C Heat treatment to obtain the C / C green body; control the density of the C / C green body to 1.1g / cm 3 ;

[0023] c. Place the C / C green body prepared in the step b in a heat-resistant mold, and control the vacuum degree to be -0.1MPa, so that the C / C green body is vacuum-impregnated with PMR-15 polyimide resin ethanol solution , control the solid content of the PMR-15 polyimide resin ethanol solution to be 38%, so that the C / C green body impregnated body is preformed;

...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

[0030] In this embodiment, a method for preparing a low thermal conductivity C / C-PI composite material comprises the following steps:

[0031] a. Carbonize the polyacrylonitrile pre-oxidized felt at 950°C;

[0032] b. Using propylene as a carbon source, deposit pyrolytic carbon on the polyacrylonitrile pre-oxygenated felt substrate after the treatment in step a by chemical vapor infiltration (CVI), control the deposition temperature to be 950°C, and then undergo a high temperature of 2300°C Heat treatment to obtain the C / C green body; control the density of the C / C green body to be 1.3g / cm 3 ;

[0033] c. Place the C / C green body prepared in the step b in a heat-resistant mold, and control the vacuum degree to be -0.1MPa, so that the C / C green body is vacuum-impregnated with PMR-15 polyimide resin ethanol solution , control the solid content of the PMR-15 polyimide resin ethanol solution to ...

Embodiment 3

[0040] This embodiment is basically the same as the previous embodiment, and the special features are:

[0041] In this embodiment, a method for preparing a low thermal conductivity C / C-PI composite material comprises the following steps:

[0042] a. Carbonize the polyacrylonitrile pre-oxidized felt at 950°C;

[0043] b. Using propylene as a carbon source, deposit pyrolytic carbon on the polyacrylonitrile pre-oxygenated felt substrate after the treatment in step a by chemical vapor infiltration (CVI), control the deposition temperature to be 950°C, and then undergo a high temperature of 2300°C Heat treatment to obtain the C / C green body; control the density of the C / C green body to 1.5g / cm 3 ;

[0044] c. Place the C / C green body prepared in the step b in a heat-resistant mold, and control the vacuum degree to be -0.1MPa, so that the C / C green body is vacuum-impregnated with PMR-15 polyimide resin ethanol solution , control the solid content of the PMR-15 polyimide resin et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com