Liquid water-soluble fertilizer and preparation method thereof

A water-soluble fertilizer, liquid technology, applied in nitrogen fertilizer, magnesium fertilizer, potash fertilizer and other directions, can solve the problem of wasting labor and achieve the effect of reducing pesticide residues, promoting transformation, and comprehensive nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

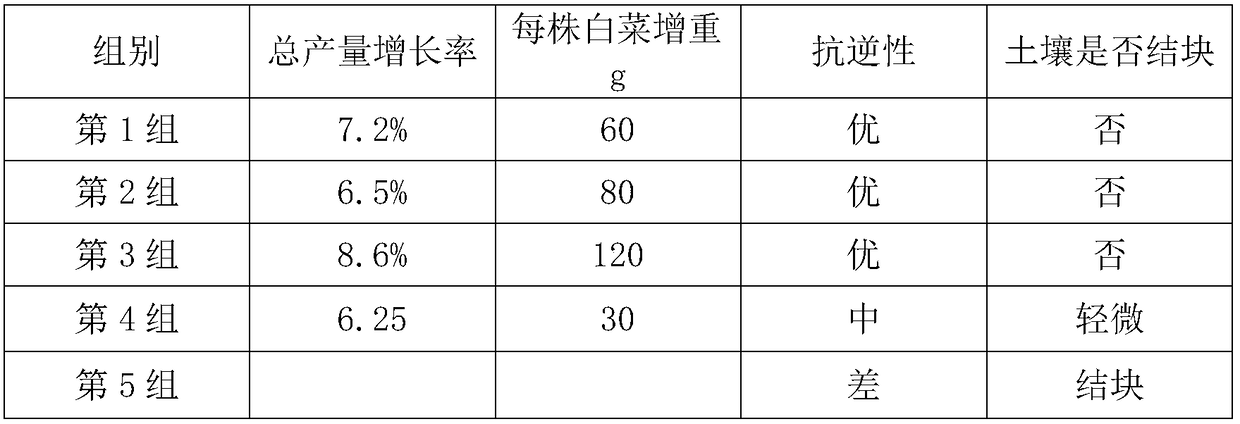

Examples

Embodiment 1

[0023] 1. Prepare large and medium element solutions: weigh urea, monoammonium phosphate, potassium sulfate and potassium dihydrogen phosphate respectively according to the mass ratio of 30:16:15:13, add 30 parts of water, Stir for 30 minutes under the condition of shear emulsification and stirring, add disodium calcium edetate and disodium magnesium edetate with a mass ratio of 40:40, stir for 30 minutes to form a homogeneous liquid, and stand for 8 hours for backup use;

[0024] 2. Add 20% water and 15% organic matter into the mixing tank, heat to 60-70°C, keep warm for 30 minutes, add 28.8% large and medium element solutions, stir until the solids are completely dissolved; pump into the reaction kettle, add 14.2% Trace elements, 4% humic acid, 16% potassium fulvic acid, stirred for 50 minutes, cooled to 35°C to obtain a slurry, which was put into a slurry buffer tank to thicken;

[0025] 3. Add 2% talcum powder, maintain the temperature at 60-65°C, filter through a 100-mes...

Embodiment 2

[0027] 1. Prepare large and medium element solutions: Weigh ammonium nitrate, ammonium polyphosphate, and potassium dihydrogen phosphate respectively according to the mass ratio of 40:45:36, add 26 parts of water, and stir under shear emulsification at a speed of 1100 rpm Stir under conditions for 20 minutes, add calcium nitrate tetrahydrate, magnesium nitrate decahydrate, magnesium sulfate such as mass ratio 30:37, stir for 30 minutes, form a homogeneous liquid, stand for 10 hours after standby;

[0028] 2. Add 20% water and 17% organic matter into the mixing tank, heat to 60-65°C, keep warm for 40 minutes, add 25% large and medium element solutions, stir until the solids are completely dissolved; pump into the reaction kettle, add 11% Trace elements, 6% humic acid, and 18% potassium fulvic acid were stirred for 40 minutes, cooled to 30°C to obtain a slurry, and put into a slurry buffer tank to thicken;

[0029] 3. Add 3% talcum powder, maintain the temperature at 60-65°C, fi...

Embodiment 3

[0031] 1. Prepare large and medium element solutions: Weigh monoammonium phosphate, ammonium polyphosphate, potassium dihydrogen phosphate, and potassium chloride according to the mass ratio of 30:46:28:23, add 30 parts of water, and rotate at 1000 rpm Stir for 40 minutes under the condition of shear emulsification and stirring for 40 minutes, add magnesium sulfate, magnesium acetate, calcium acetate and calcium nitrate with a mass ratio of 49:35:32:30, stir for 30 minutes to form a homogeneous liquid, and let stand for 8 hours reserve;

[0032] 2. Add 13% water and 12% organic matter into the mixing tank, heat to 55-65°C, keep warm for 40 minutes, add 30% large and medium element solutions, stir until the solids are completely dissolved; pump into the reaction kettle, add 16% Trace elements, 6% humic acid, 18% potassium fulvic acid, stirred for 60 minutes, and cooled to 38°C to obtain a slurry, which was put into a slurry buffer tank to thicken;

[0033] 3. Add 5% talcum pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com