A special grinding aid for Raymond mill

A technology of grinding aids and alcohol amines, applied in the field of cement admixtures, can solve the problems of low crushing and grinding capacity, reduced air flow, affecting output, etc., to improve the activity index and fluidity value, increase material fluidity, reduce The effect of production power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

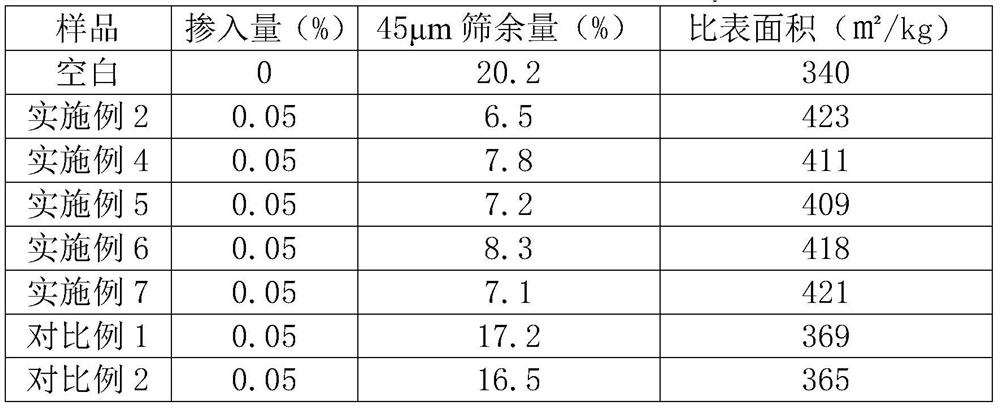

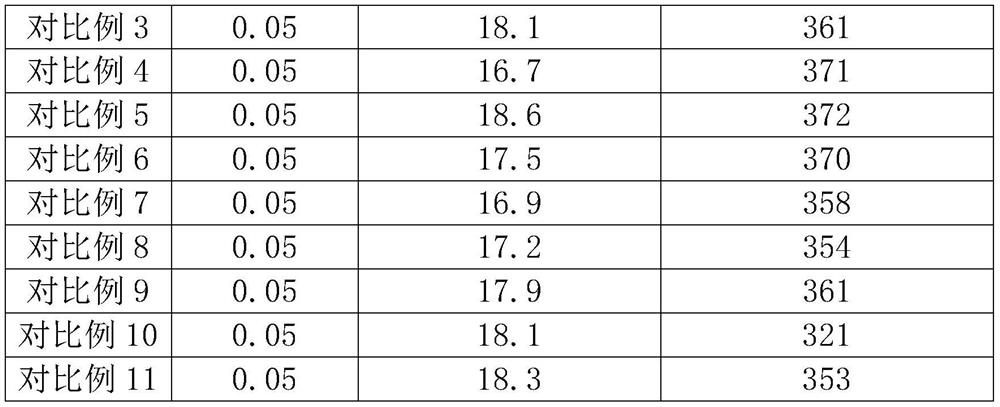

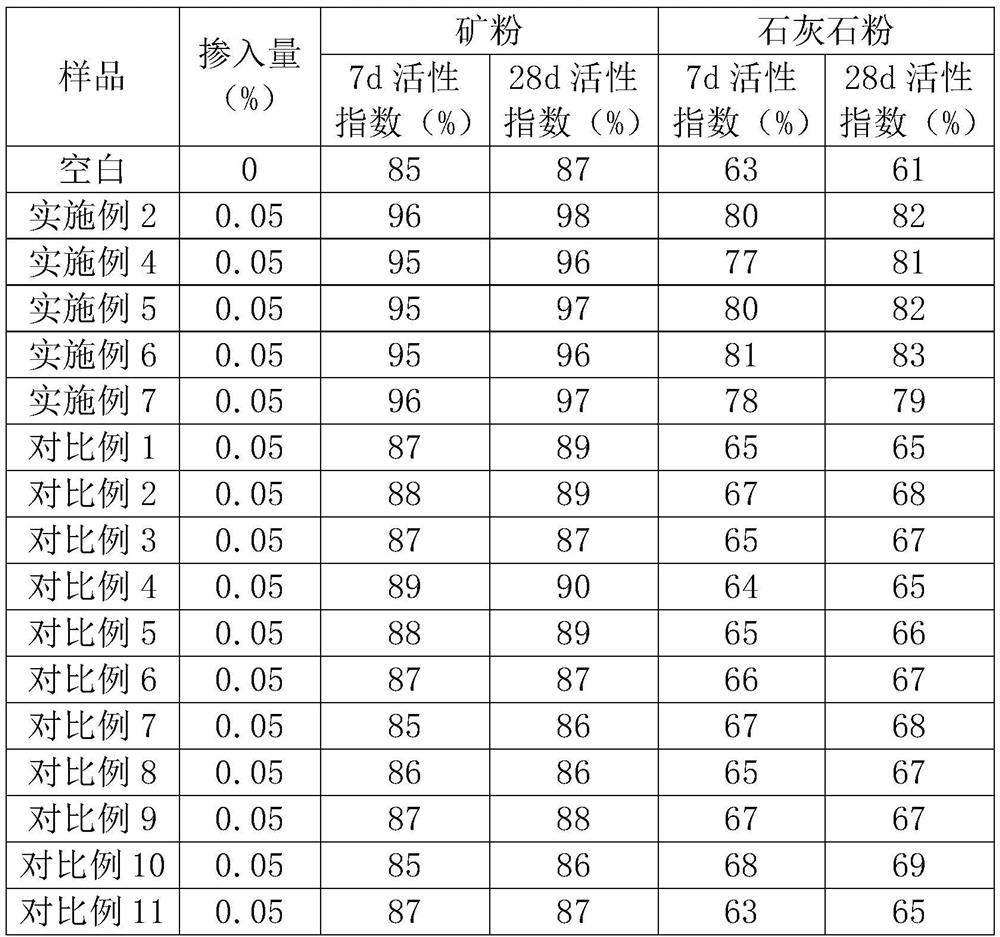

Examples

Embodiment 1

[0027] A grinding aid specially used for Raymond mills, made of the following raw materials in parts by weight: 45 parts of alcohol amines, 20 parts of glycerol, 5 parts of diethylene glycol, 20 parts of calcium lignosulfonate, sodium phosphate 3 parts, 2 parts of dodecyl phosphate monoesters, 10 parts of vinyl glycol ethers; the alcohol amines are diethanol monoisopropanolamine and ethanol diisopropanolamine with a weight ratio of 2:1 mixture.

Embodiment 2

[0029] A grinding aid specially used for Raymond mills, made of the following raw materials in parts by weight: 51 parts of alcohol amines, 15 parts of glycerol, 10 parts of diethylene glycol, 14 parts of sodium lignosulfonate, sodium phosphate 7 parts, 5 parts of dodecyl phosphate monoesters, 7 parts of vinyl glycol ethers; the alcohol amines are diethanol monoisopropanolamine and ethanol diisopropanolamine with a weight ratio of 2:1 mixture.

Embodiment 3

[0031] A grinding aid specially used for Raymond mills, made of the following raw materials in parts by weight: 60 parts of alcohol amines, 10 parts of glycerol, 15 parts of diethylene glycol, 8 parts of sodium lignosulfonate, pyrosulfonate 10 parts of sodium phosphate, 9 parts of dodecyl phosphate monoester, 3 parts of vinyl glycol ether; the alcohol amines are diethanol monoisopropanolamine and ethanol diisopropyl alcohol in a weight ratio of 2:1 A mixture of alcohols and amines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com