Preparation and Application of TiO Photoelectrode with Controlled Exposure of {001} Crystal Planes

A titanium dioxide and photoelectrode technology, which is applied in the field of environmental pollution treatment technology and material chemistry, can solve problems such as affecting paths and rates, and achieve the effects of promoting separation, high-efficiency photoelectric catalytic performance, and high-efficiency photoelectric synergistic catalytic oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A {001} TiO with Controlled Exposure of {001} Crystal Planes 2 The preparation method of / Ti photoelectrode specifically comprises the following steps:

[0025] (1) The titanium plate is chemically polished in a polishing solution mixed with nitric acid, hydrofluoric acid and water. The ratio of the polishing solution is nitric acid: hydrofluoric acid: water volume ratio 3:1:6.

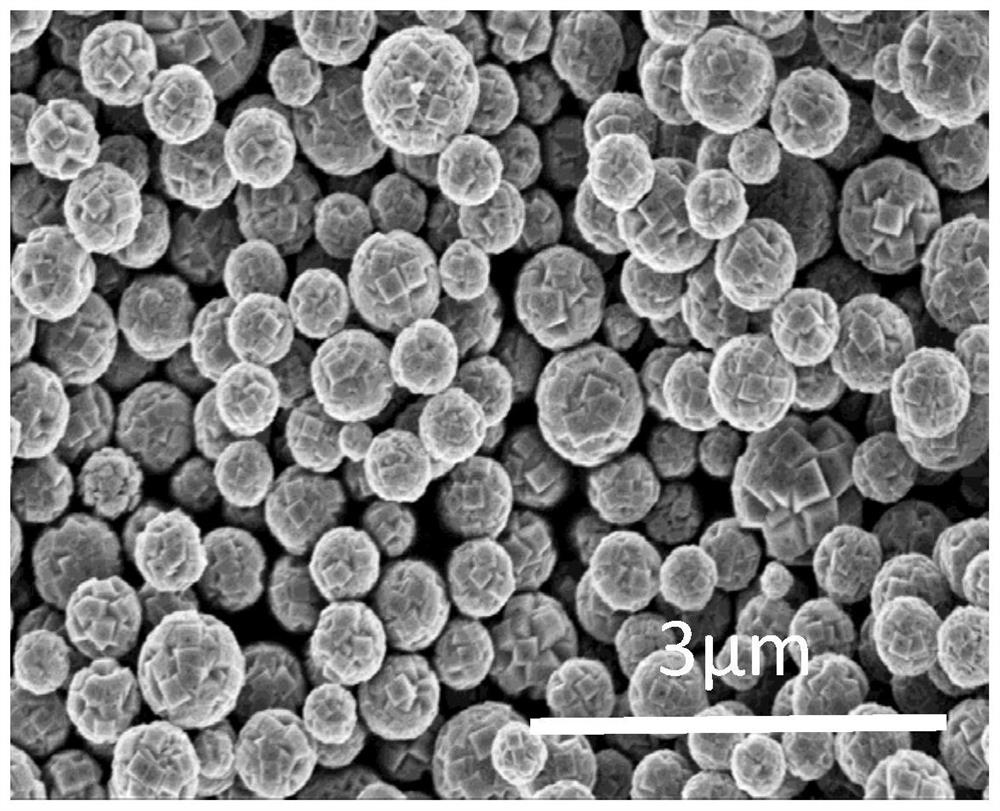

[0026] (2) Mix the hydrofluoric acid of 27uL (≥38wt%) with the deionized water of 30mL, stir evenly, move into the autoclave of 100mL, put into step (1) through the titanium plate of chemical polishing process, seal, Hydrothermal reaction was carried out in an oven at 180°C for 4h.

[0027] (3) After the reaction in step (2) is completed, cool the reactor at room temperature, take it out, rinse it with deionized water, and let it dry naturally. Under air atmosphere, the heating rate was 3°C / min, the calcination temperature was 450°C, and the calcination time was 3h. That is, get 4h-{001}TiO ...

Embodiment 2

[0030] A {001} TiO with Controlled Exposure of {001} Crystal Planes 2 The preparation method of / Ti photoelectrode specifically comprises the following steps:

[0031] (1) The titanium plate is chemically polished in a polishing solution mixed with nitric acid, hydrofluoric acid and water. The ratio of the polishing solution is nitric acid: hydrofluoric acid: water volume ratio 3:1:6.

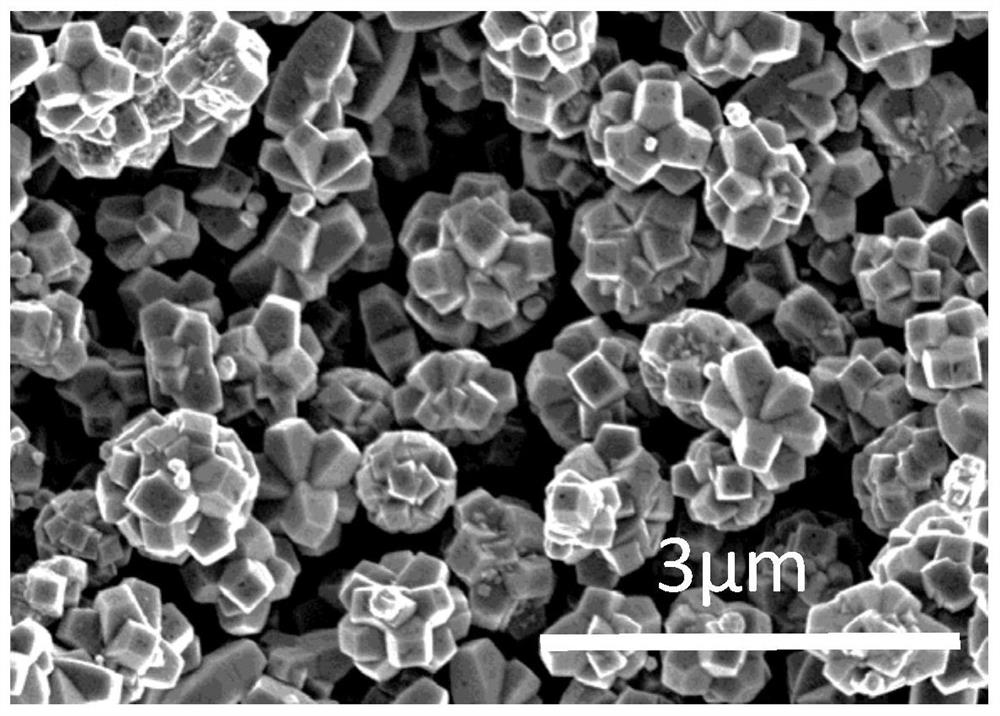

[0032] (2) Mix the hydrofluoric acid of 27uL (≥38wt%) with the deionized water of 30mL, stir evenly, move into the autoclave of 100mL, put into step (1) through the titanium plate of chemical polishing process, seal, Hydrothermal reaction was carried out in an oven at 180°C for 2h.

[0033] (3) After the reaction in step (2) is completed, cool the reactor at room temperature, take it out, rinse it with deionized water, and let it dry naturally. Under air atmosphere, the heating rate was 3°C / min, the calcination temperature was 450°C, and the calcination time was 3h. That is to get 2h-{001}TiO...

Embodiment 3

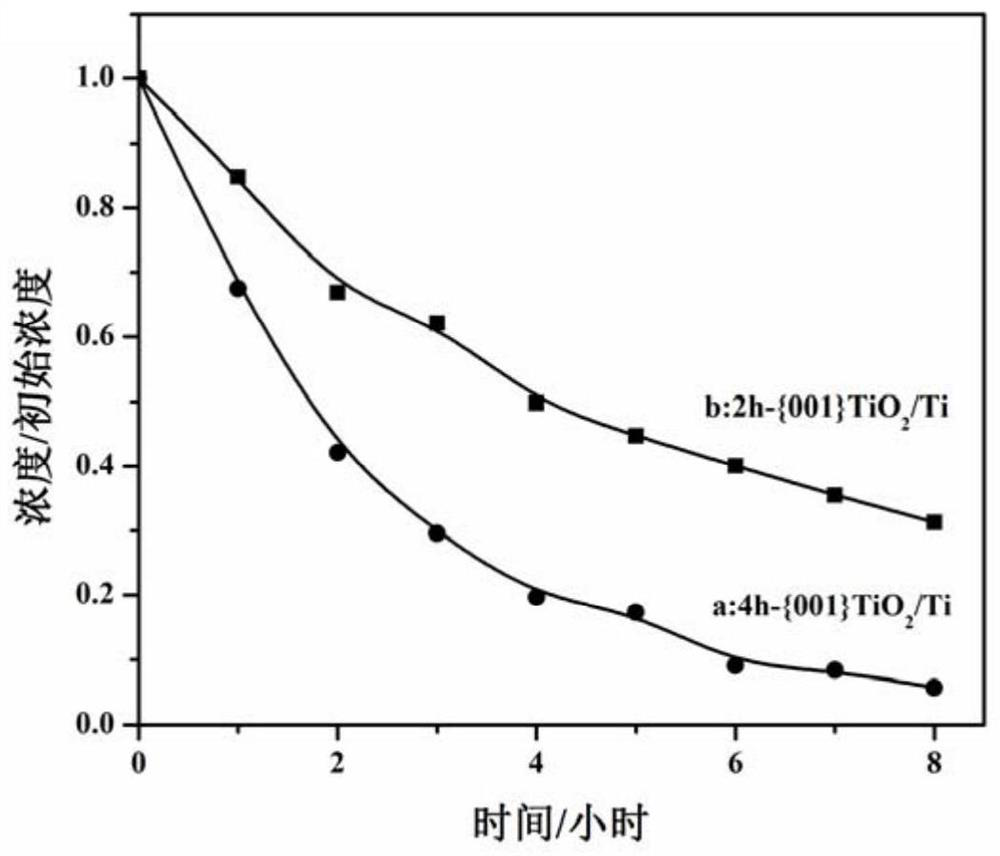

[0036] Using 2h-{001}TiO prepared in Example 2 2 / Ti photoelectrode ({001} crystal surface exposure ratio 30%) photoelectrically degrades DMP simulated wastewater efficiently, and the specific steps include the following:

[0037] The photoelectric degradation DMP experiment was carried out in the electrochemical reaction cell, and a cup with circulating water was added to keep the constant temperature of the reaction system at 25°C. Using a three-electrode degradation system, {001}TiO 2 The / Ti electrode is the working electrode, the platinum sheet is the counter electrode, the distance between the working electrode and the counter electrode is 1cm, and the effective photoelectrode area is 3×5cm 2 . Use 0.1mol·L -1 Dimethyl phthalate was prepared into simulated wastewater with a concentration of 5mg / L in deionized aqueous solution of sodium sulfate, and the treatment volume was 100mL. Ultraviolet xenon lamp (main wavelength is 365nm) as the light source, the light intensit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com