A preparation method of ultra-wide and highly wear-resistant plastic-absorbing and coated environmentally friendly veneer

A high wear-resistant and veneer technology, which is applied in the jointing of wooden veneers, chemical instruments and methods, wood heating, etc., can solve the problems that cannot meet the needs of special-shaped parts, such as blistering, coating treatment, and rough and uneven surface appearance of decorative veneers. Satisfy processing and production problems, and achieve the effects of wide processing range, high barrier ability, aging resistance and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

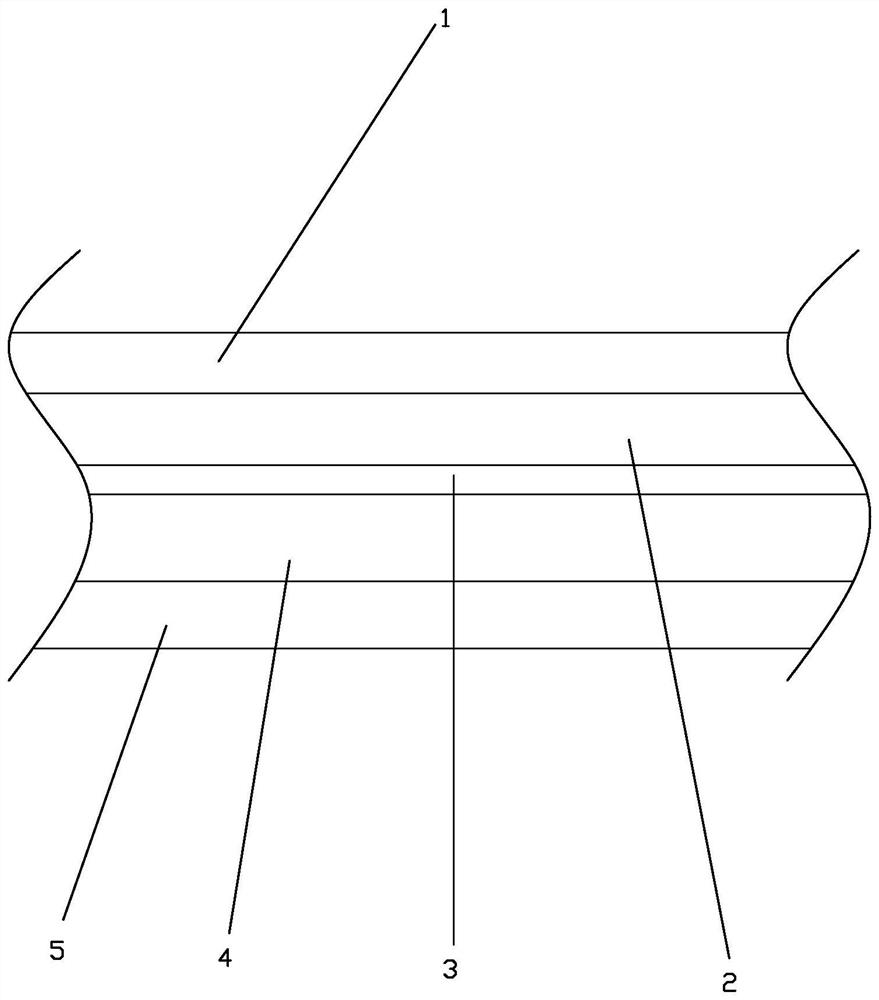

Image

Examples

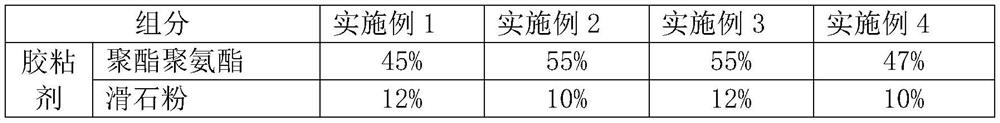

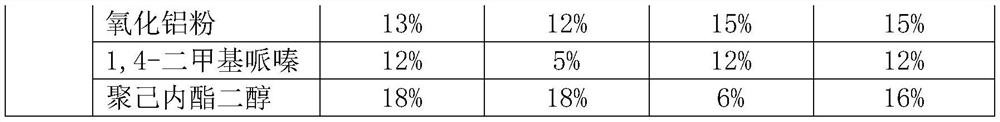

Embodiment 1

[0029] A method for preparing an ultra-wide, highly wear-resistant, plastic-absorbing, and environmentally-friendly veneer-coated method, comprising the following steps:

[0030] a. Composite: apply adhesive on the veneer, and then flatten the non-woven fabric on the veneer, the weight of the non-woven fabric is 4g / ㎡;

[0031] b. Toughening and constant humidity: put the composite veneer into the cooking equipment, the water temperature in the cooking equipment is raised from normal temperature to 45°C and then kept at the temperature, the duration of the heating is 1.5h, and then the temperature is raised from 45°C to 55°C, The heating duration is 2 hours, and the water in the cooking equipment is replaced once after cooking, and the temperature is slowly raised again. After repeating the above heating process twice, it is then dried by a belt dryer. Constant temperature and humidity in a closed environment until the moisture content of the veneer is 12%;

[0032] c. Piecing...

Embodiment 2

[0037] A method for preparing an ultra-wide, highly wear-resistant, plastic-absorbing, and environmentally-friendly veneer-coated method, comprising the following steps:

[0038] a. Composite: apply adhesive on the veneer, and then flatten the non-woven fabric on the veneer. The weight of the non-woven fabric is 15g / ㎡;

[0039] b. Toughening and constant humidity: put the composite veneer into the cooking equipment, the water temperature in the cooking equipment is raised from normal temperature to 45°C and then kept at the temperature. The duration is 3 hours, and the water in the cooking equipment is replaced once after cooking, and the temperature is slowly raised again. After repeating the above heating process 2 times, it is then dried by a belt dryer. Constant temperature and humidity in the environmental conditions until the moisture content of the veneer is 10%;

[0040]c. Piecing: The veneer is spliced infinitely and seamlessly along the vertical direction to ensur...

Embodiment 3

[0045] A method for preparing an ultra-wide, highly wear-resistant, plastic-absorbing, and environmentally-friendly veneer-coated method, comprising the following steps:

[0046] a. Composite: apply adhesive on the veneer, and then flatten the non-woven fabric on the veneer, the weight of the non-woven fabric is 25g / ㎡;

[0047] b. Toughening and constant humidity: put the composite veneer into the cooking equipment, the water temperature in the cooking equipment is raised from normal temperature to 45°C and then kept at the temperature, the duration of the heating is 1h, and then the temperature is raised from 45°C to 55°C, and the temperature is raised The duration is 3 hours, and the water in the cooking equipment is replaced once after cooking, and the temperature is slowly raised again. After repeating the above heating process 2 times, it is then dried by a belt dryer. Constant temperature and humidity in the environmental conditions until the moisture content of the vene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com