Outer circle grinding bed

A cylindrical grinding machine and bed technology, applied in the mechanical field, can solve the problems that affect the subsequent processing of workpieces and the formulation of quality inspection standards, the axis of the thimble cannot be completed, and the coaxiality is not very good, so as to reduce the space occupied by the grinding machine. , the processing quality is consistent, the effect of saving manufacturing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

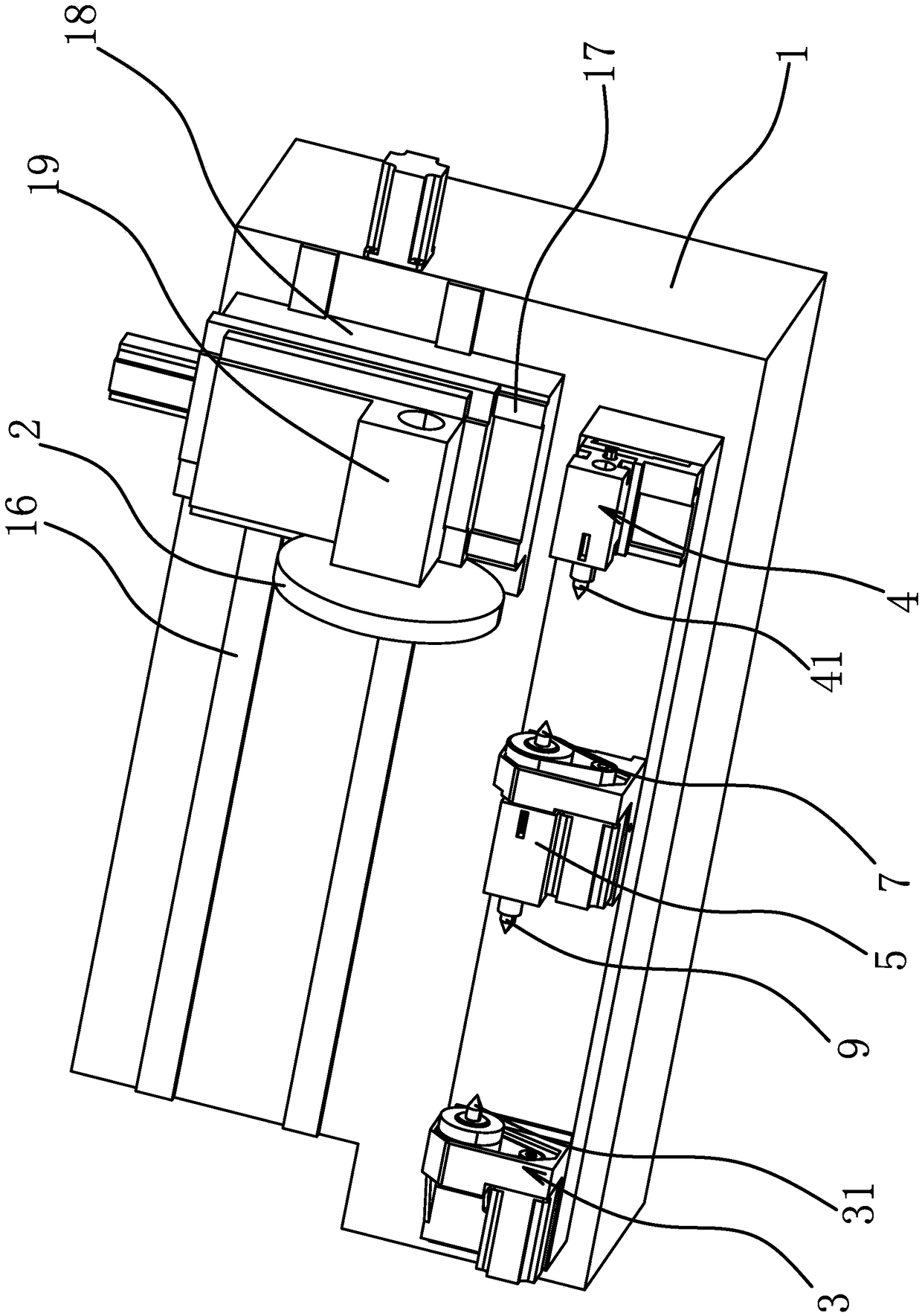

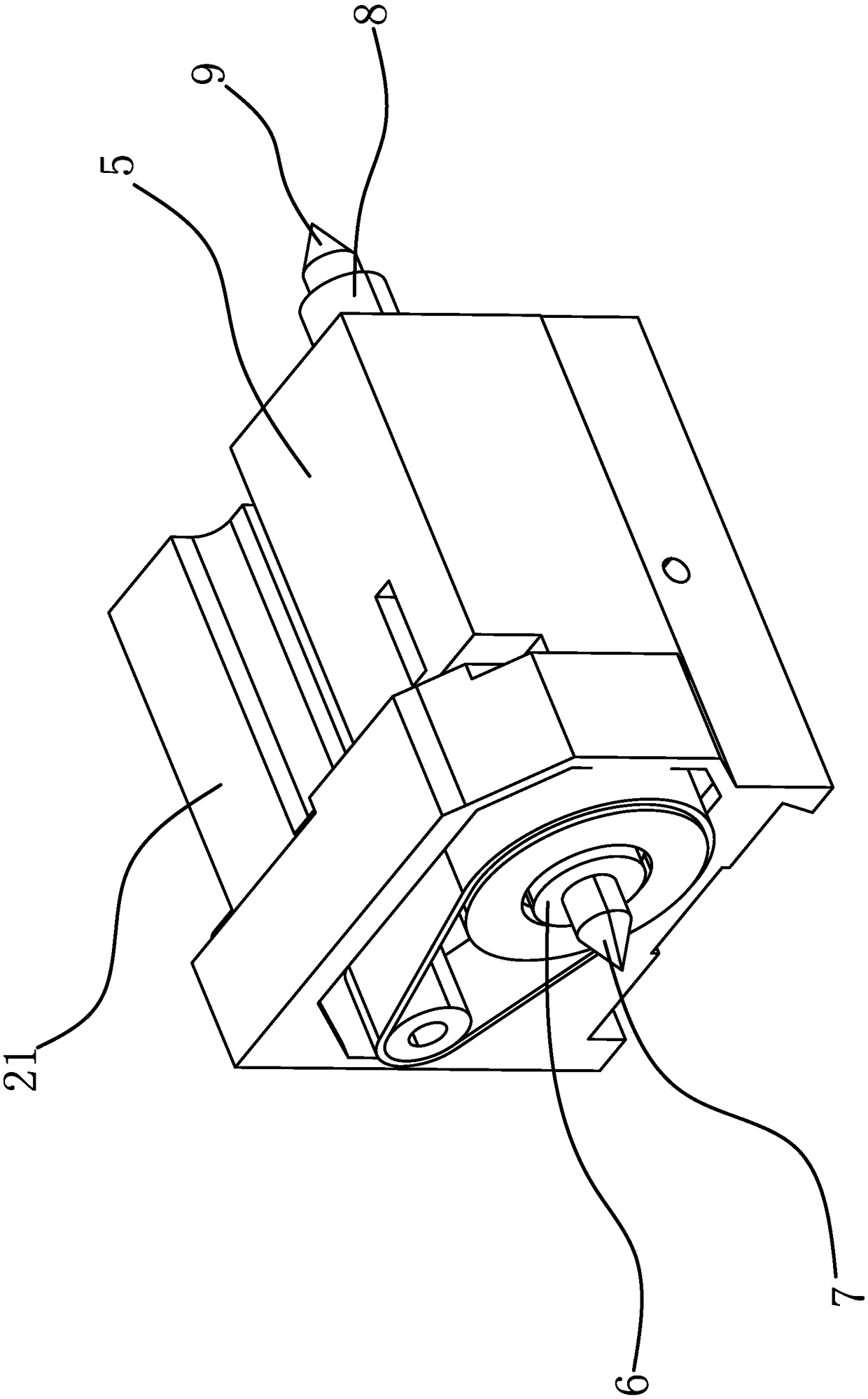

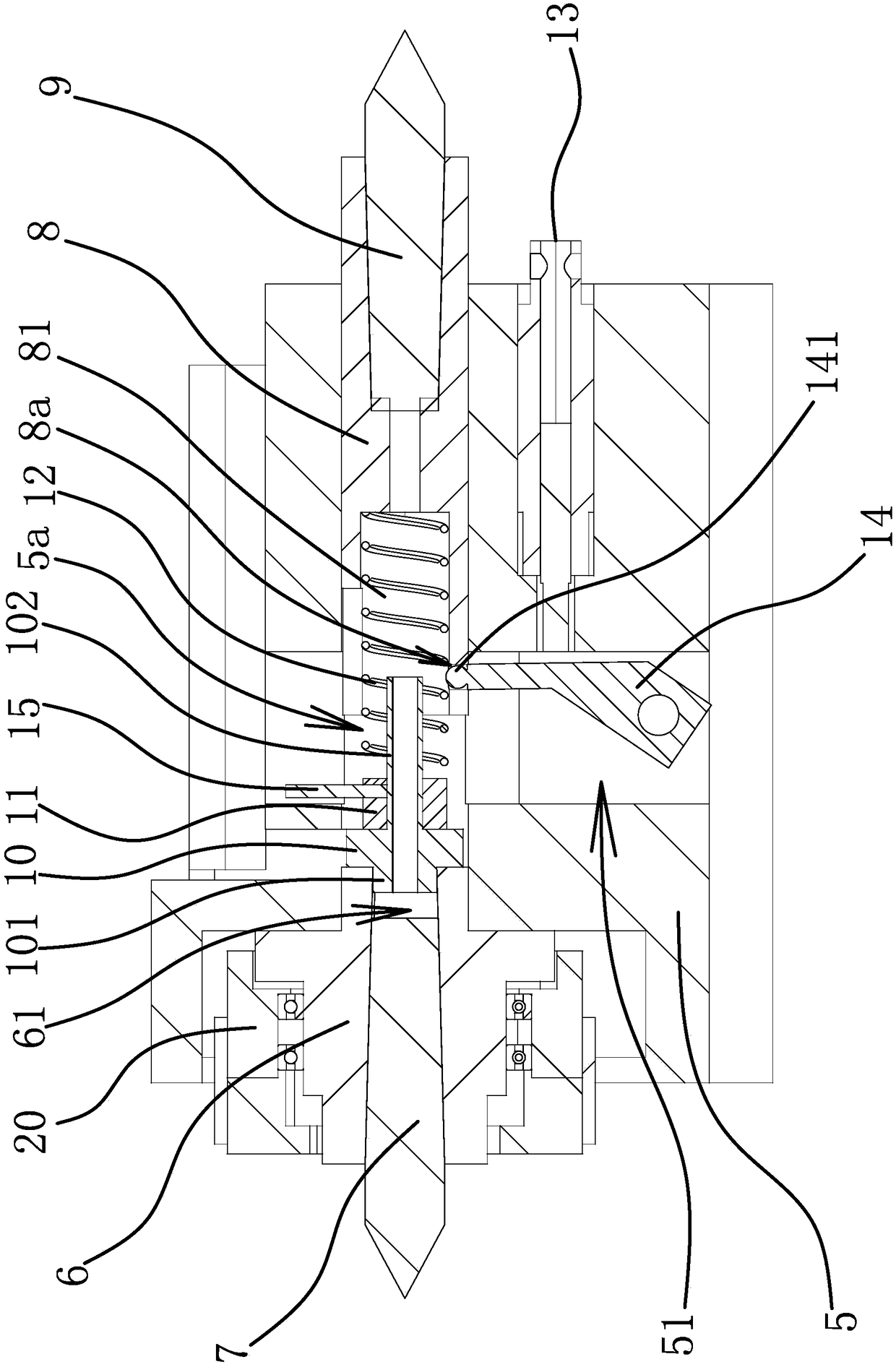

[0032] Specifically, as figure 1 As shown, the cylindrical grinding machine includes a bed 1 and a grinding head 2 that can move relative to the bed 1 . Wherein, the lathe bed 1 is fixed with the horizontal slide rail 16 that arranges along the horizontal direction, and the supporting plate 18 is slidably connected with on the horizontal slide rail 16, and the vertical slide rail 17 that is arranged along the longitudinal direction is fixed on the supporting plate 18, and slides on the vertical slide rail 17. A grinding head frame 19 is connected, and the grinding head 2 is arranged on the grinding head frame 19 . At the same time, the bed 1 is provided with a left clamping seat 3 and a right clamping seat 4, the left thimble 31 of the left clamping seat 3 is coaxially arranged with the right thimble 41 of the right clamping seat 4, the left clamping seat 3 and the right An integrated seat 5 is arranged between the clamping seats 4 . In this embodiment, the left clamping sea...

Embodiment 2

[0037] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as Figure 6 As shown, in this embodiment, the transmission mechanism includes a driving rod 14 arranged in the installation cavity 51, one end of the driving rod 14 is fixed on the sliding sleeve 8, and the driving member 13 can push the driving rod 14 along the axis of the installation through hole 5a Move inward.

Embodiment 3

[0039] In the embodiment, both the left clamping seat 3 and the right clamping seat 4 are head frames, and the corresponding integrated thimble 1 7 and the corresponding integrated thimble 2 9 are telescopic thimbles that can be stretched.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com