Valve rod plane semi-automatic lathe

A semi-automatic and flat technology, applied in the field of lathes, can solve the problems of lengthy valve stem processing process and low valve stem production efficiency, and achieve the effect of shortening processing time, facilitating equipment maintenance and reducing processing flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

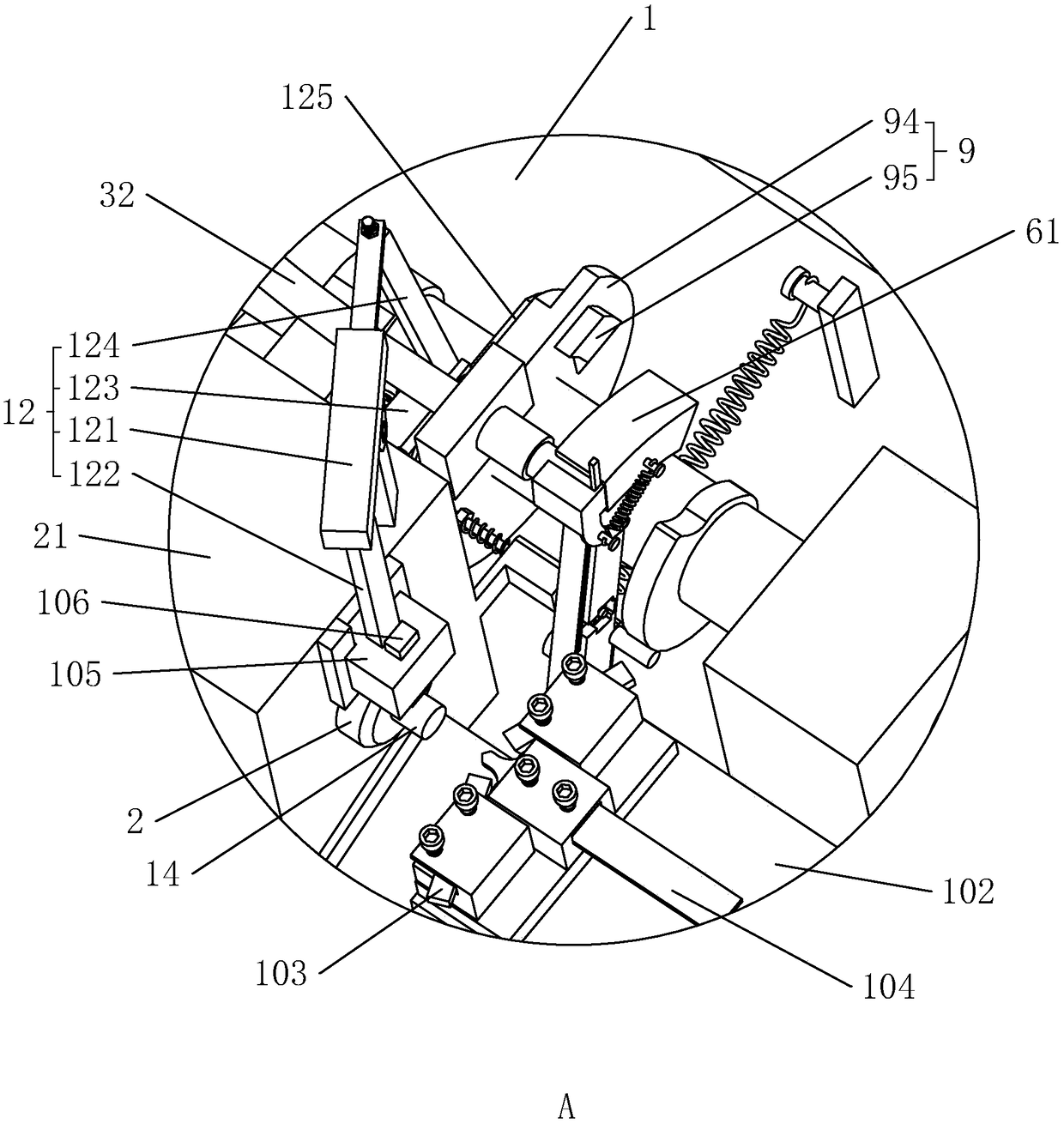

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

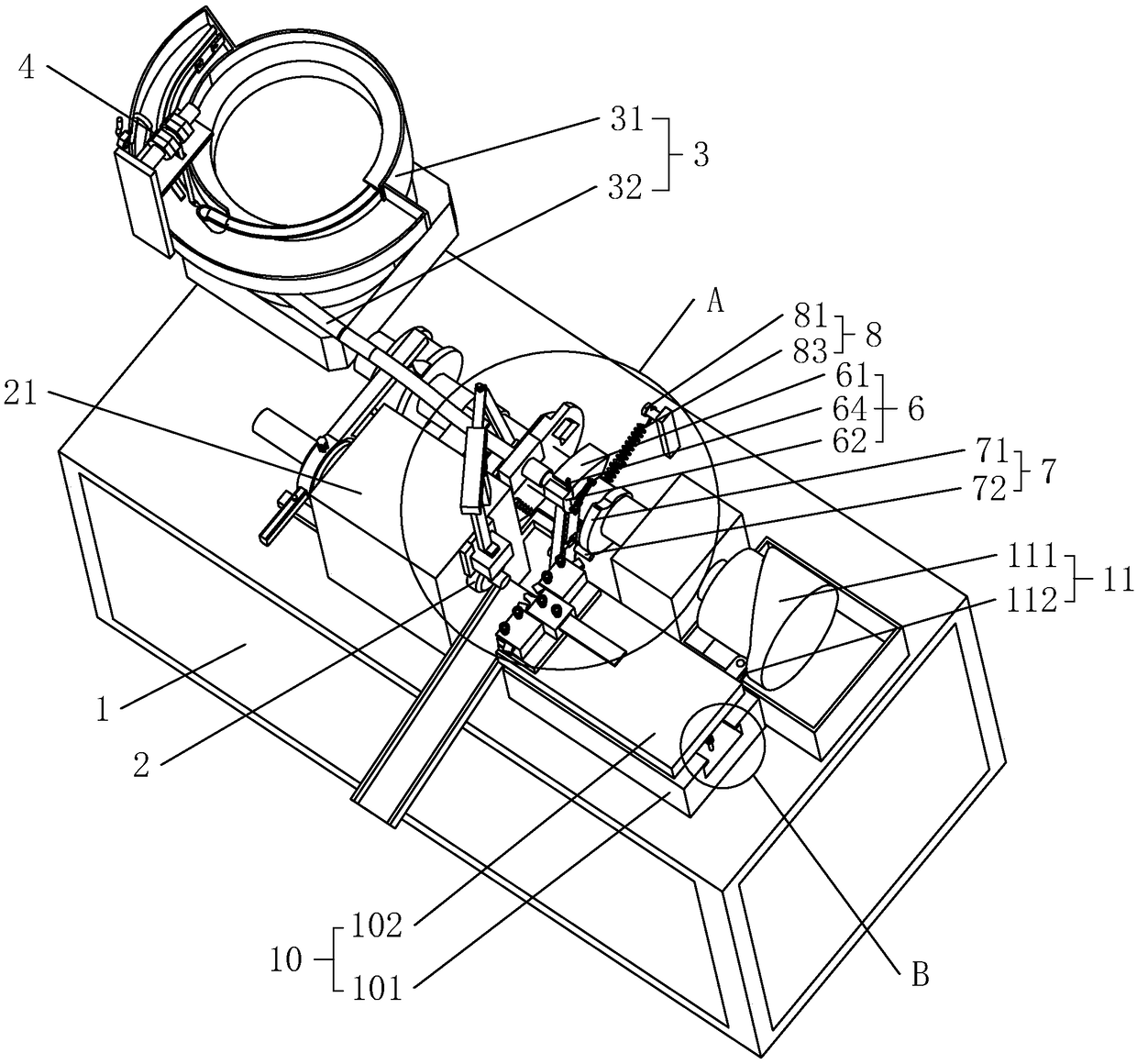

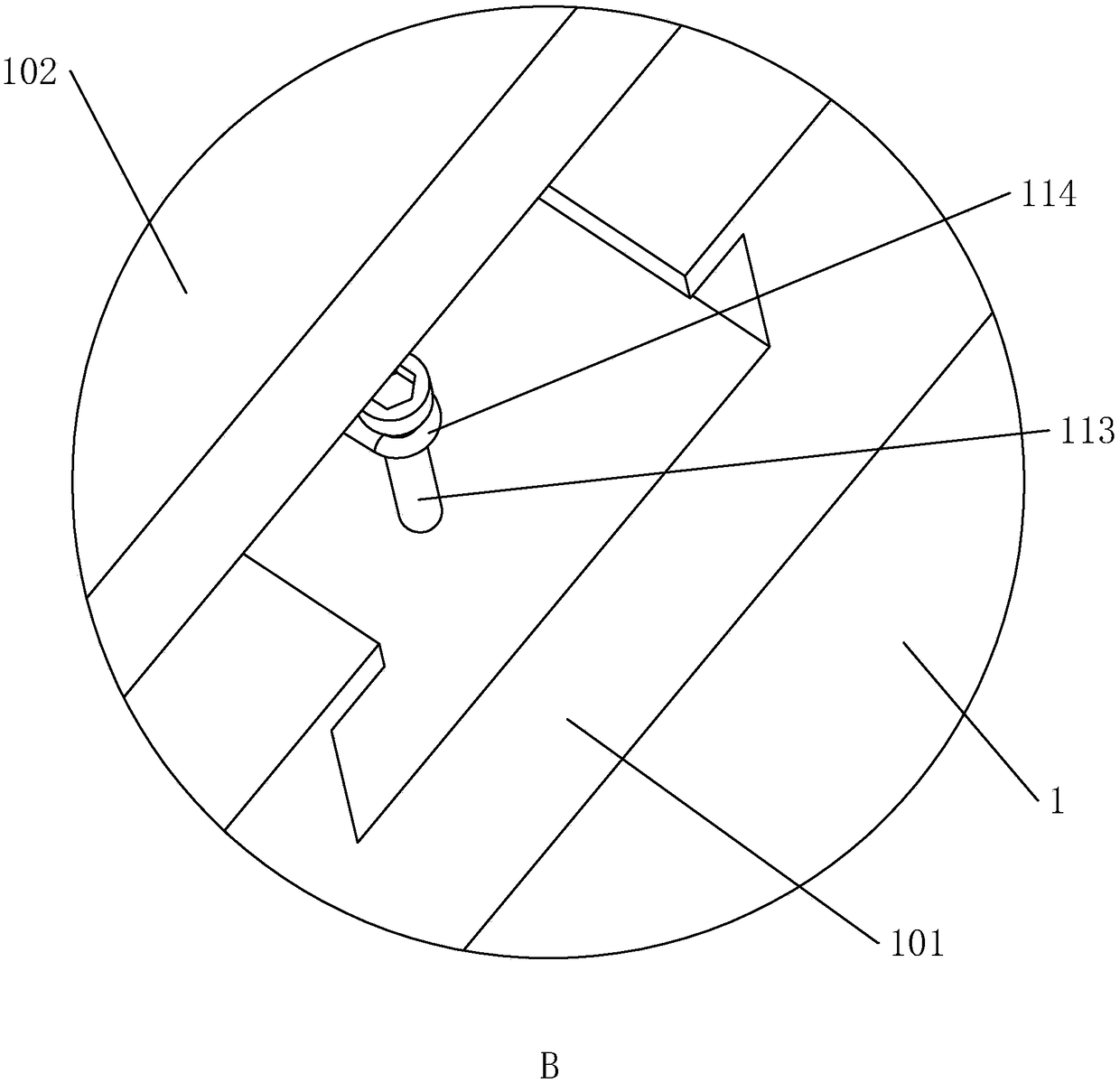

[0037] Such as figure 1 As shown, a valve stem plane semi-automatic lathe includes a frame 1, a main shaft 2, a feeding device 3, a feeding device 6, and a turning device 10. The main shaft 2 is connected to the frame 1 through a mounting seat 21 in rotation; A charging slot for inserting the rod 14 is provided on the installation end, and the main shaft 2 is driven to rotate by a motor.

[0038] The feeding device 3 includes a vibrating plate 31 and a feeding pipe 32. The vibrating plate 31 is fixed on the frame 1. It is a device that uses the principle of vibration to transport parts. It is widely used in the field of mechanical processing and is located in the hopper of the vibrating plate 31. After the parts are vibrated, they rise along the spiral track. During the rising process, after a series of orbital screening or posture changes, the parts can aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com