Oxide dispersion strengthening iron-base alloy powder and characterization method thereof

A technology of dispersion strengthening and iron-based alloys, applied in metal processing equipment, instruments, material analysis using wave/particle radiation, etc., can solve problems such as public reports of unseen research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: Fe-14Cr-3W-0.4Ti-1.5Y 2 o 3 (wt.%) Preparation of alloy powder

[0078] Powder preparation:

[0079] First, weigh the gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder and Y 2 o 3 A total of 150g of powder was put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2o 3 Powder particle size is less than or equal to 45μm. According to the ball-to-material ratio of 10:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 1500g of grinding balls and put them into the ball milling tank.

[0080] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0081] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 300r / min, and the mechanical ball milling ...

Embodiment 2

[0094] Embodiment 2: Fe-14Cr-3W-0.4Ti-1.0Y 2 o 3 (wt.%) Preparation of alloy powder

[0095] Powder preparation:

[0096] First, according to the mass ratio of 99:1, weigh the gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder and Y 2 o 3 A total of 150g of powder was put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 75μm. According to the ball-to-material ratio of 10:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 1500g of grinding balls and put them into the ball milling tank.

[0097] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0098] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 320r...

Embodiment 3

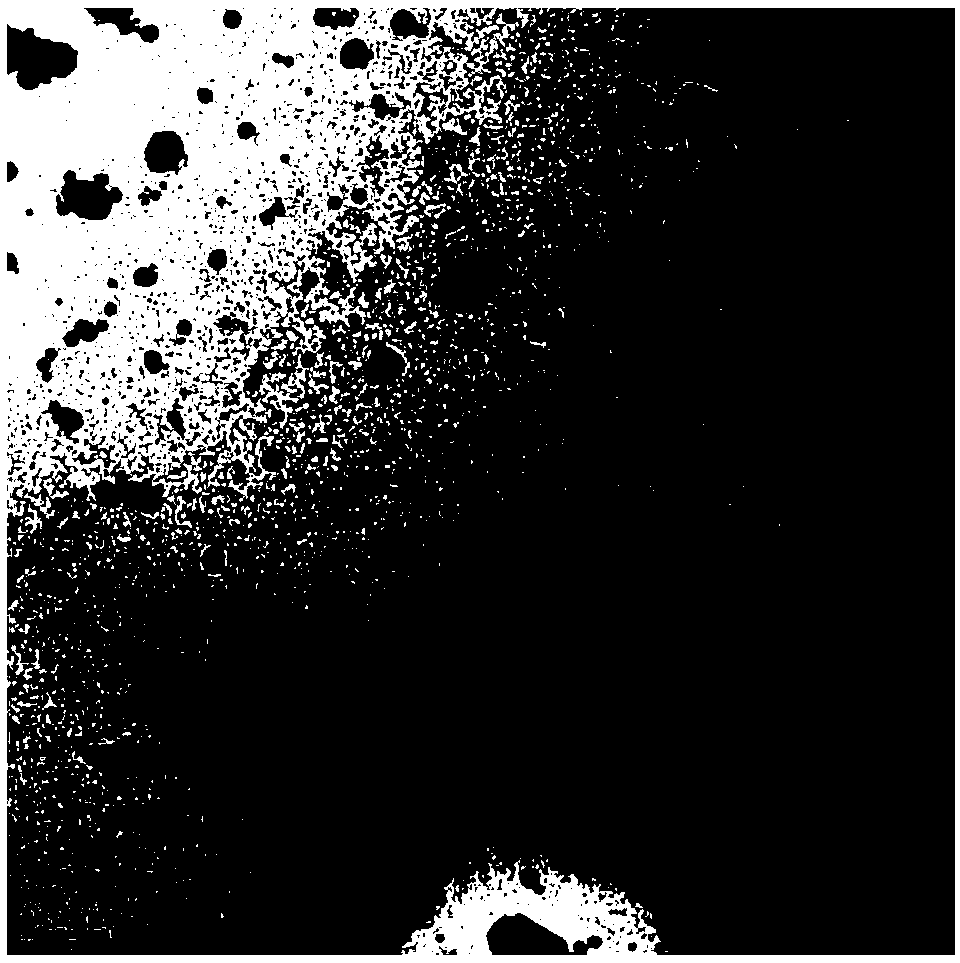

[0121] Using the oxide dispersion strengthened iron-based alloy powder prepared in Example 1, the iron-based alloy with multi-scale and multi-phase dispersion strengthened is prepared through hot extrusion forming, hot rolling and heat treatment in sequence.

[0122] Alloy preparation:

[0123] The first step: put the above-mentioned alloy iron-based powder into a pure iron sheath, vacuumize to less than or equal to 0.1Pa, and seal and weld the trachea. Carry out hot extrusion forming, the hot extrusion parameters are: extrusion temperature 850°C, extrusion speed 15mm / s, extrusion ratio 10:1; then use wire cutting to separate the sheath to obtain ODS iron-based alloy after thermoforming.

[0124] The second step: hot-rolling the hot-extruded ODS iron-based alloy, the hot-rolling parameters are: temperature 850°C, total deformation 80%.

[0125] Step 3: heat-treat the hot-rolled ODS iron-based alloy, and the heat-treatment parameters are as follows: temperature 950° C., heat p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com