Preparation method of adsorbent for removing aflatoxin in peanut oil

A kind of aflatoxin and adsorbent technology, applied in the field of adsorbent preparation, can solve the problems of peanut oil human health hazards, scattered peanut oil processing points, and failure to meet market demand, and achieve the effects of reducing production costs, enhancing activity, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

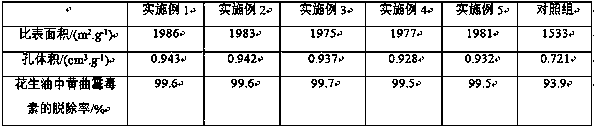

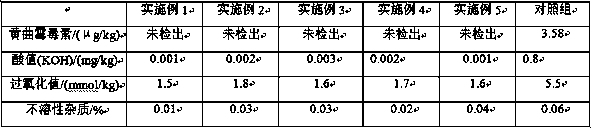

Examples

Embodiment 1

[0019] Preparation of activated carbon: Take 26 parts of longan branches, 28 parts of lychee branches, and 25 parts of bagasse, dry them at 120°C, and then pulverize them to obtain mixed powder A. Add 25 parts of rice husk powder to obtain mixed powder B, then impregnate mixed powder B with 14 parts of [bmim]OH alkaline ionic liquid for 36 hours, put mixed powder B impregnated in alkaline ionic liquid into a drying oven at 105 ° C After drying, put it in a muffle furnace for carbonization treatment. Before carbonization, nitrogen gas is introduced as a protective gas. The carbonization temperature is set at 500 ° C, and the carbonization time is 55 minutes. Activated carbon is obtained after drying;

[0020] Preparation of aminated activated carbon: Take the activated carbon prepared in step 1), add 42 parts of 9mol / L nitric acid solution, stir at 66°C for 9 hours, then filter with suction, wash with distilled water until neutral, dry at 105°C, and then add excess The thionyl...

Embodiment 2

[0023] Preparation of activated carbon: Take 28 parts of longan branches, 26 parts of lychee branches, and 24 parts of bagasse, dry them at 105°C, and then pulverize them to obtain mixed powder A. Add 20 parts of rice husk powder to obtain mixed powder B, then impregnate mixed powder B with 15 parts of [bmim][OAc] alkaline ionic liquid for 30 h, put mixed powder B impregnated in alkaline ionic liquid in a drying oven at 120 After drying at ℃, place it in a muffle furnace for carbonization treatment. Before carbonization, nitrogen gas is introduced as a protective gas. The carbonization temperature is set at 520°C, and the carbonization time is 60 minutes. After carbonization, the initial activated carbon product obtained is pickled and rinsed. , to obtain activated carbon after drying;

[0024] Preparation of aminated activated carbon: Take the activated carbon prepared in step 1), add 48 parts of 9mol / L nitric acid solution, stir at 70°C for 8.5h, then filter with suction, wa...

Embodiment 3

[0027] Preparation of activated carbon: take 25 parts of longan branches, 29 parts of lychee branches, and 20 parts of bagasse, dry them at 115°C, and then pulverize them to obtain mixed powder A. Add 22 parts of rice husk powder to obtain mixed powder B, then impregnate mixed powder B with 13 parts of [PemIm]Mes alkaline ionic liquid for 33h, put mixed powder B impregnated in alkaline ionic liquid into a drying oven and bake at 110°C After drying, put it in a muffle furnace for carbonization treatment. Before carbonization, nitrogen gas is introduced as a protective gas. The carbonization temperature is set at 600 ° C, and the carbonization time is 58 minutes. Activated carbon is obtained after drying;

[0028] Preparation of aminated activated carbon: Take the activated carbon prepared in step 1), add 40 parts of 9mol / L nitric acid solution, stir at 68°C for 10 hours, then filter with suction, wash with distilled water until neutral, dry at 115°C, and then add excess The th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com