A kind of preparation method of metal-doped molybdenum disulfide thin film

A molybdenum disulfide and metal doping technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of harsh doping conditions, poor controllability of metal doped molybdenum disulfide, etc. Short, easy to operate, good controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method specifically includes the following steps:

[0028] (1) Dissolving thiourea and molybdenum salt in an alcoholic solvent, wherein the molar ratio of sulfur to molybdenum is 20:1 to 5:1 to obtain a precursor solution; the molybdenum salt is molybdenum chloride or ammonium molybdate, The alcoholic solvent is isopropanol or ethanol, preferably stirred at a temperature of 60-100°C and a rotational speed of 1500-2000r / min for 0.8-1.5 hours to dissolve thiourea and molybdenum salt in the alcoholic solvent. The sulfur element concentration in the precursor solution is 15-25g / L, and the molybdenum element concentration is 4-12g / L. By adjusting the concentration ratio of sulfur element and molybdenum element, the growth size of molybdenum sulfide film can be controlled.

[0029] (2) After the metal salt solution is mixed with the precursor solution described in step (1), it is coated on the substrate to obtain a substrate coated with the precursor solution...

Embodiment 1

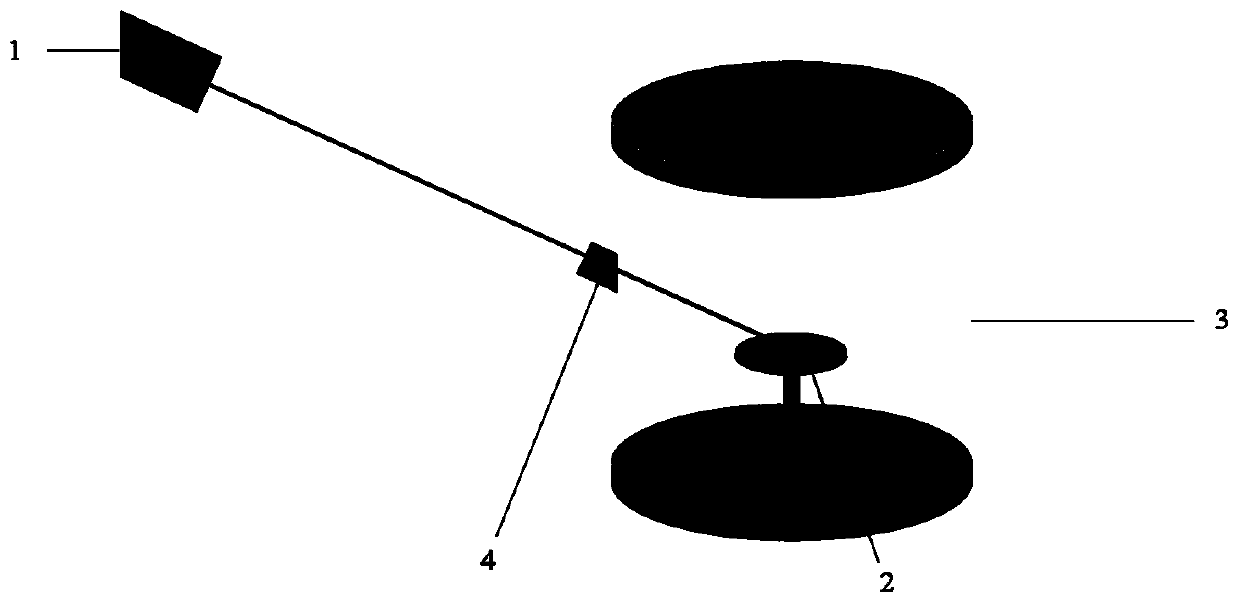

[0039] Add 200mg of thiourea, 80mg of molybdenum pentachloride, and 3.75ml of isopropanol into the flask, and stir magnetically for 1 hour to obtain a precursor solution. The rotational speed of the magnetic stirring is 1800r / min, and the temperature is 80°C. Take 0.1ml of the precursor solution and 0.1ml of gold chloride solution with a molar concentration of 5mmol / L, mix them well, spin coat them evenly on the substrate, place them in a vacuum chamber, and irradiate the substrate with a pulsed laser through the laser window. The schematic diagram of the device is as figure 1 As shown, the laser power is set to 250mJ, the radiation frequency is 3Hz, the number of pulses is 2000 times, the spot size is 3mm×3mm, and the laser moving speed is 3mm / s. After the laser irradiation is completed, the substrate is taken out from the vacuum chamber to obtain a gold-doped molybdenum disulfide thin film.

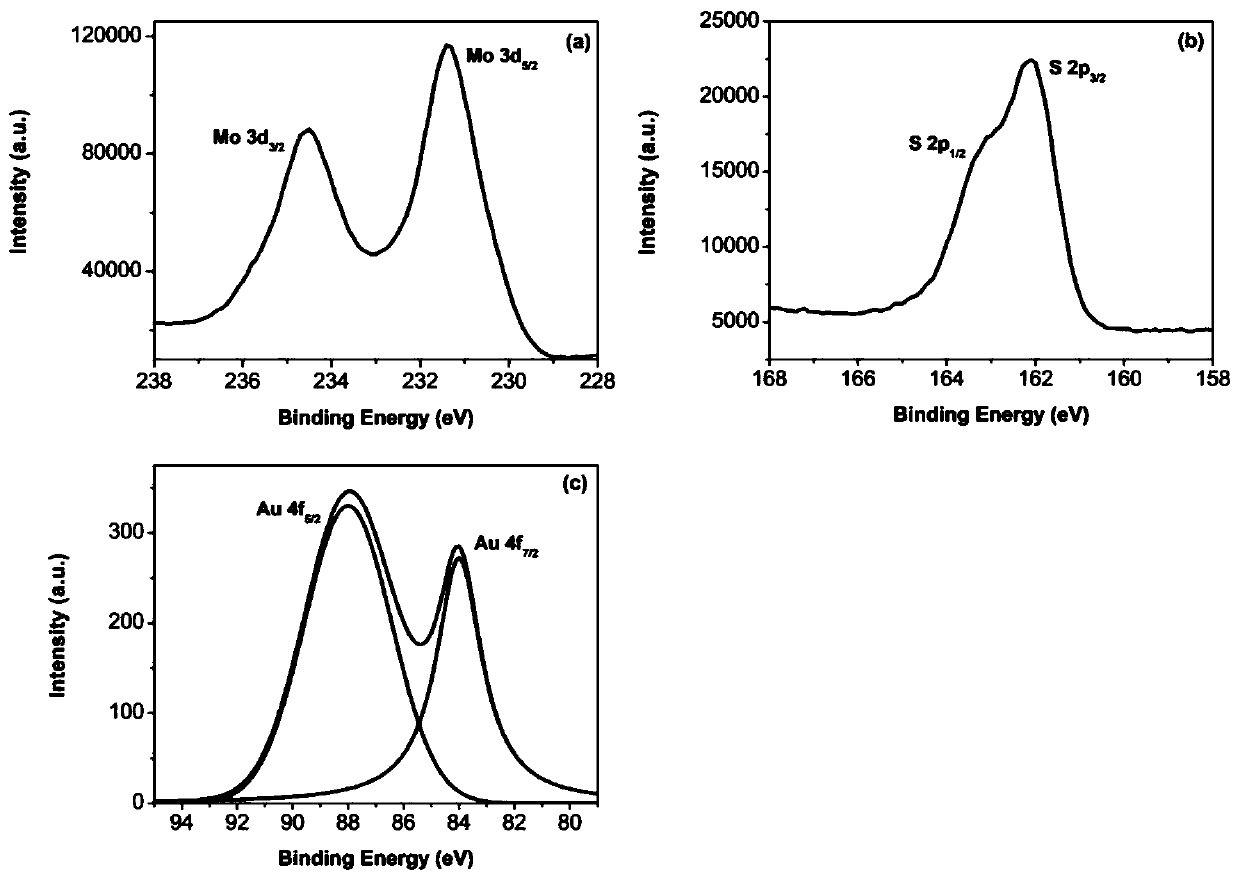

[0040] figure 2 It is the XPS figure of the gold-doped molybdenum disulfide film...

Embodiment 2

[0042] Add 200mg of thiourea, 60mg of molybdenum pentachloride, and 3.75ml of isopropanol into the flask, and stir magnetically for 1.5 hours to obtain a precursor solution. The rotational speed of the magnetic stirring is 1600r / min, and the temperature is 80°C. Take 0.1ml of the precursor solution and 0.1ml of the gold chloride solution with a molar concentration of 1mmol / L, fully mix, evenly spin-coat it on the substrate, and then place it in a vacuum chamber, and irradiate the substrate with a pulsed laser through the laser window. Set the laser power to 250mJ, the radiation frequency to 3Hz, the number of pulses to 2500 times, the spot size to 3mm×3mm, and the laser moving speed to 3mm / s. After the laser irradiation is completed, the substrate is taken out from the vacuum chamber to obtain a gold-doped molybdenum disulfide thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com