Composite preparation die made from high-performance wrought magnesium alloy

A deformed magnesium alloy, high-performance technology, applied in the field of magnesium alloy processing, can solve the problems of low density and toughness, inability to fully develop the potential of material performance, coarse grains of materials, etc., and achieve huge development potential and dynamic precipitation effect Significant, fine and uniform grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

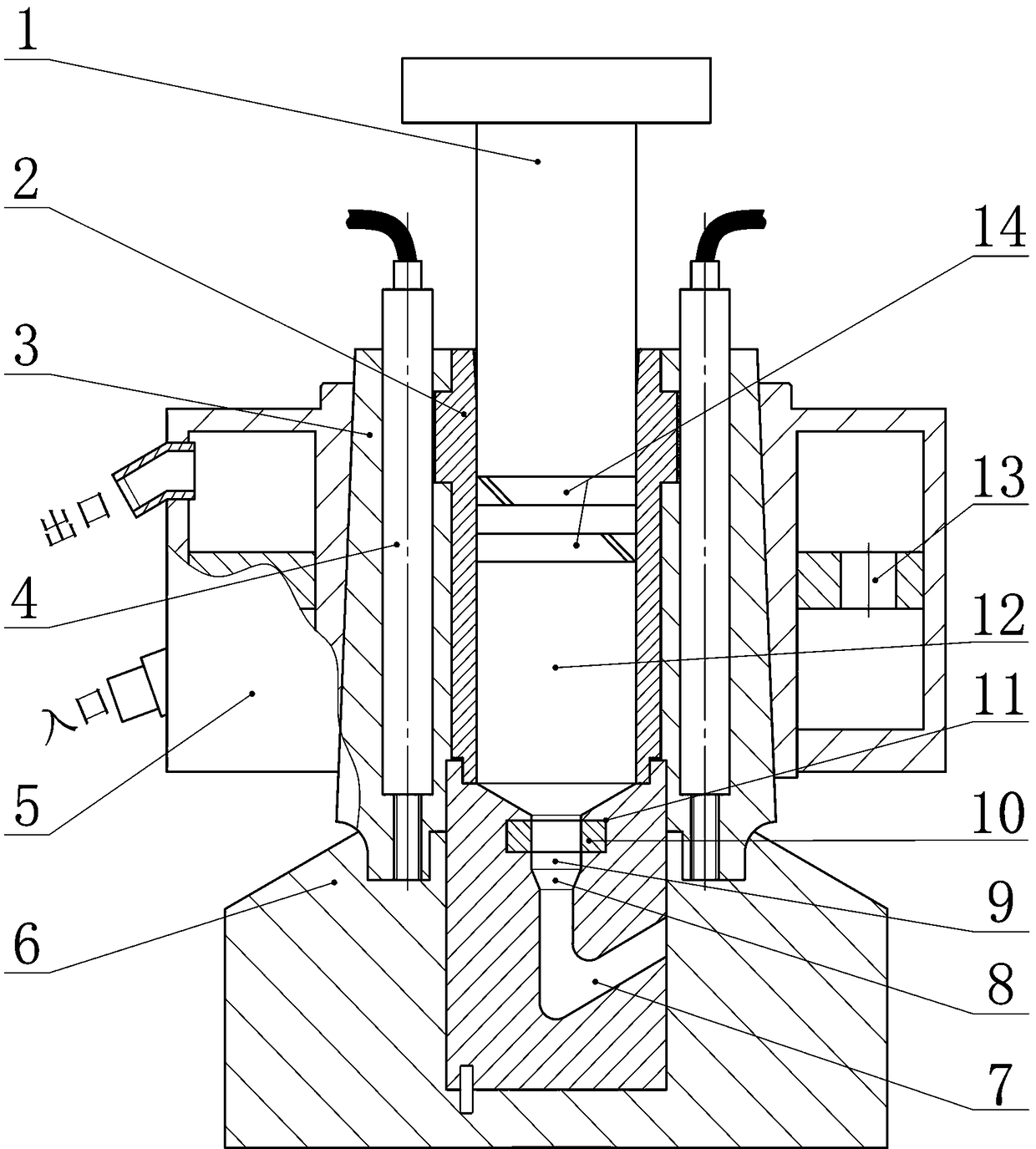

[0027] In order to illustrate the shape and structure of the present invention more clearly, ZK60-1Yb deformed magnesium alloy is used as an example material below, and the present invention is further described in detail in conjunction with the accompanying drawings.

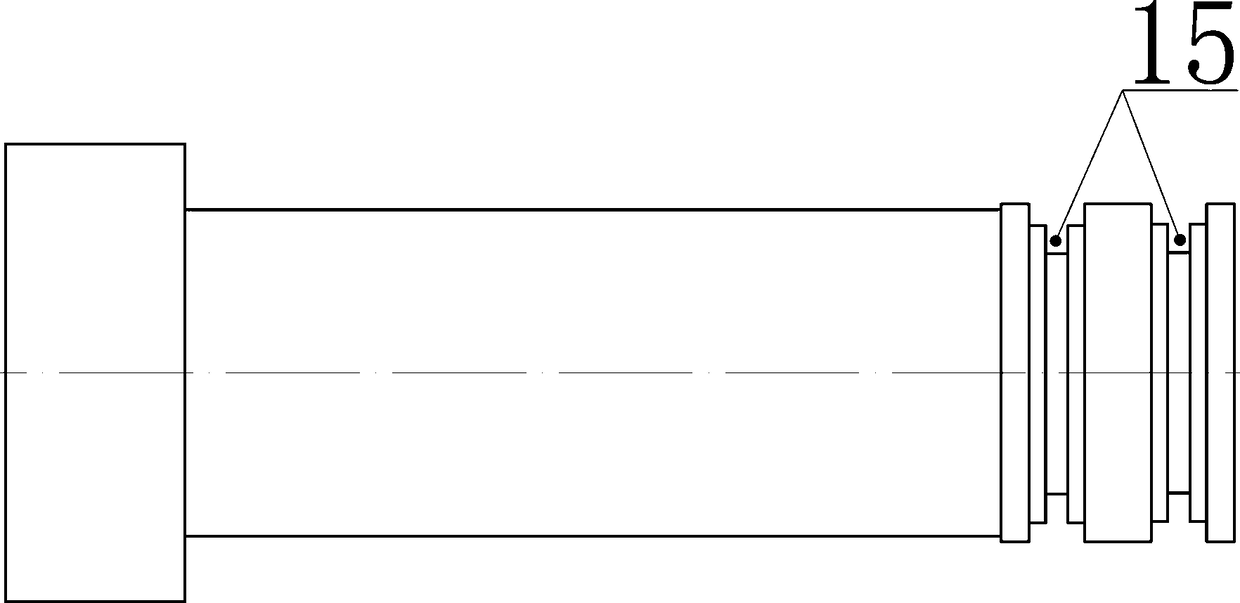

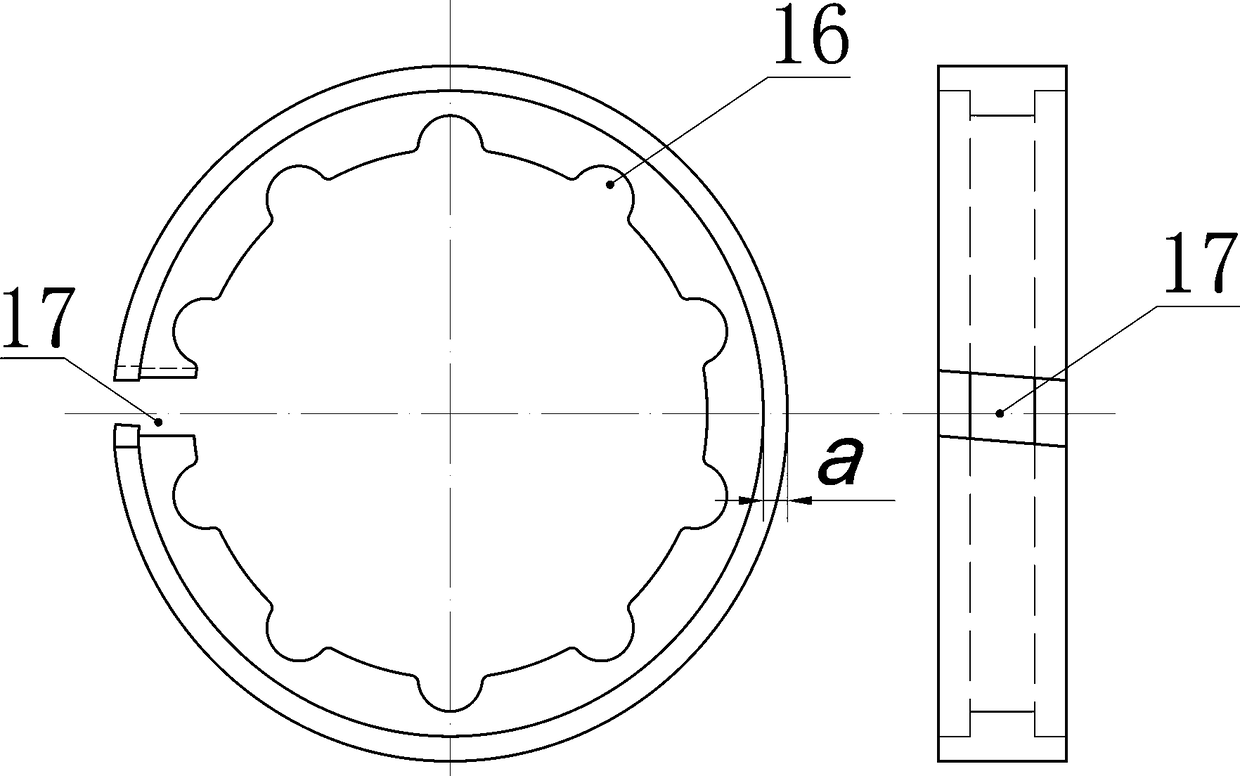

[0028] Such as figure 1 As shown, a composite mold for the preparation of a high-performance wrought magnesium alloy, which integrates gold melting, high-specific-pressure controlled-speed condensation, diameter-reducing extrusion, and equal-diameter angular extrusion; Pressing cavity 9, reduced-diameter extrusion belt 8 and equal-diameter angular extrusion cavity 7, wherein the upper end of the cavity 12 is arranged with a matching punch 1, and a movable insert is arranged in the area of the lower end extrusion cavity 9 The plate 10 is provided with an inner sleeve 2 and a heating jacket 3 covering the inner sleeve on the outer periphery. Eight heating pipes 4 are evenly arranged in the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com