A metal-organic framework mil-160 film and its preparation method and application

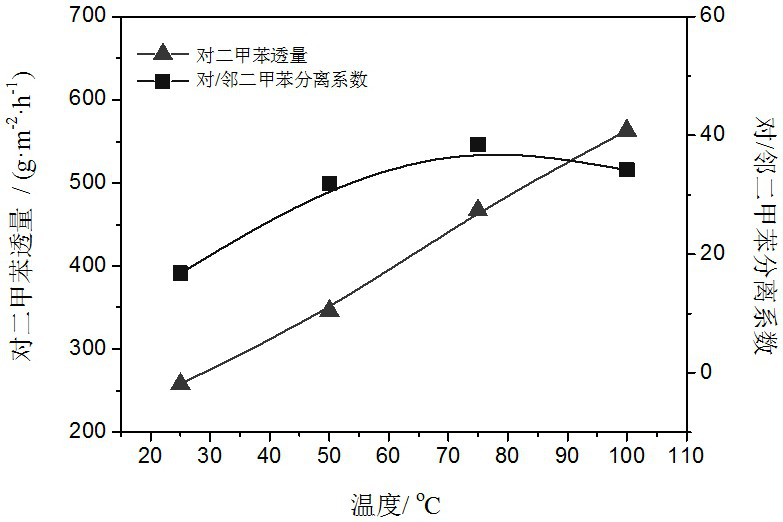

A metal-organic framework, porous alumina technology, applied in organic chemistry, chemical instruments and methods, membrane technology, etc., can solve the problems of low paraxylene flux, defects, pinhole intergranular, etc., and achieve high selective separation performance , the effect of high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

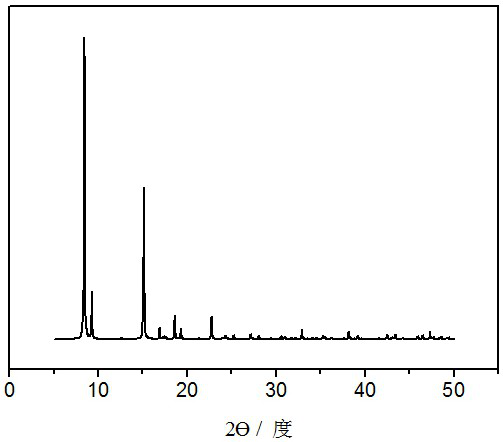

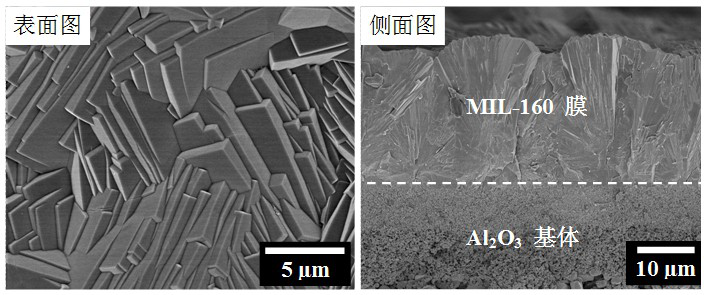

[0022] MIL-160 membranes were synthesized as follows

[0023] Step 1. Modification of Porous Alumina Matrix by Dopamine Functionalization

[0024] Dissolve 0.5 g of dopamine hydrochloride in 70 mL of distilled water, stir and mix evenly, then add tris to control the pH of the solution to 8.5. The washed and dried porous alumina matrix was put into the dopamine buffer solution, reacted at room temperature for 24 hours, rinsed with distilled water and ethanol, and dried at room temperature for 24 hours before use.

[0025] Step 2: MIL-160 film preparation

[0026] Dissolve 0.2g of aluminum trichloride hexahydrate, 0.13g of 2,5-furandicarboxylic acid, and 0.12g of sodium formate in 15g of distilled water, stir magnetically until the solution is clear, and then stir overnight to prepare MIL-160 membrane synthesis solution; Pour the synthesis solution into the reaction kettle with the dopamine-modified porous alumina substrate in step 1. After the reaction kettle was sealed, it ...

Embodiment 2

[0028] MIL-160 films were synthesized as follows:

[0029] Step 1: Modification of Porous Alumina Matrix by Dopamine Functionalization

[0030] Dissolve 0.5 g of dopamine hydrochloride in 70 mL of distilled water, stir and mix evenly, then add tris to control the pH of the solution to 9. Put the washed and dried porous alumina matrix into the dopamine buffer solution, react at room temperature for 20 h, rinse with distilled water and ethanol, and dry at room temperature for 24 h before use.

[0031] Step 2: MIL-160 film preparation

[0032]Dissolve 0.2g of aluminum trichloride hexahydrate, 0.26g of 2,5-furandicarboxylic acid, and 0.12g of sodium formate in 15g of distilled water, stir magnetically until the solution is clear, and then stir overnight to prepare MIL-160 membrane synthesis solution; Pour the synthesis solution into the reaction kettle with the dopamine-modified porous alumina substrate in step 1. After the reaction kettle was sealed, it was placed in an oven a...

Embodiment 3

[0034] MIL-160 films were synthesized as follows:

[0035] Step 1: Modification of Porous Alumina Matrix by Dopamine Functionalization

[0036] With embodiment 1 step 1.

[0037] Step 2: MIL-160 film preparation

[0038] Dissolve 0.2g of aluminum trichloride hexahydrate, 0.26g of 2,5-furandicarboxylic acid, and 0.08g of sodium hydroxide in 15g of distilled water, magnetically stir until the solution is clear, and then stir overnight to prepare MIL-160 film synthesis liquid; pour the synthesis liquid into the reactor with the dopamine-modified porous alumina substrate in step 1. After the reaction kettle was sealed, it was placed in an oven and reacted at 100° C. for 24 hours. After the reaction, take it out, rinse it with distilled water, and dry it at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com