Vitamin E selenium microcapsule tablet and preparation method and application thereof

A technology of vitamins and microcapsules, which can be used in applications, anti-toxins, and pill delivery. It can solve the problems of cell membrane and cell wall peroxidation damage, activity reduction, etc., and achieve the effects of preventing human cell damage, easy absorption, and improving immunity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

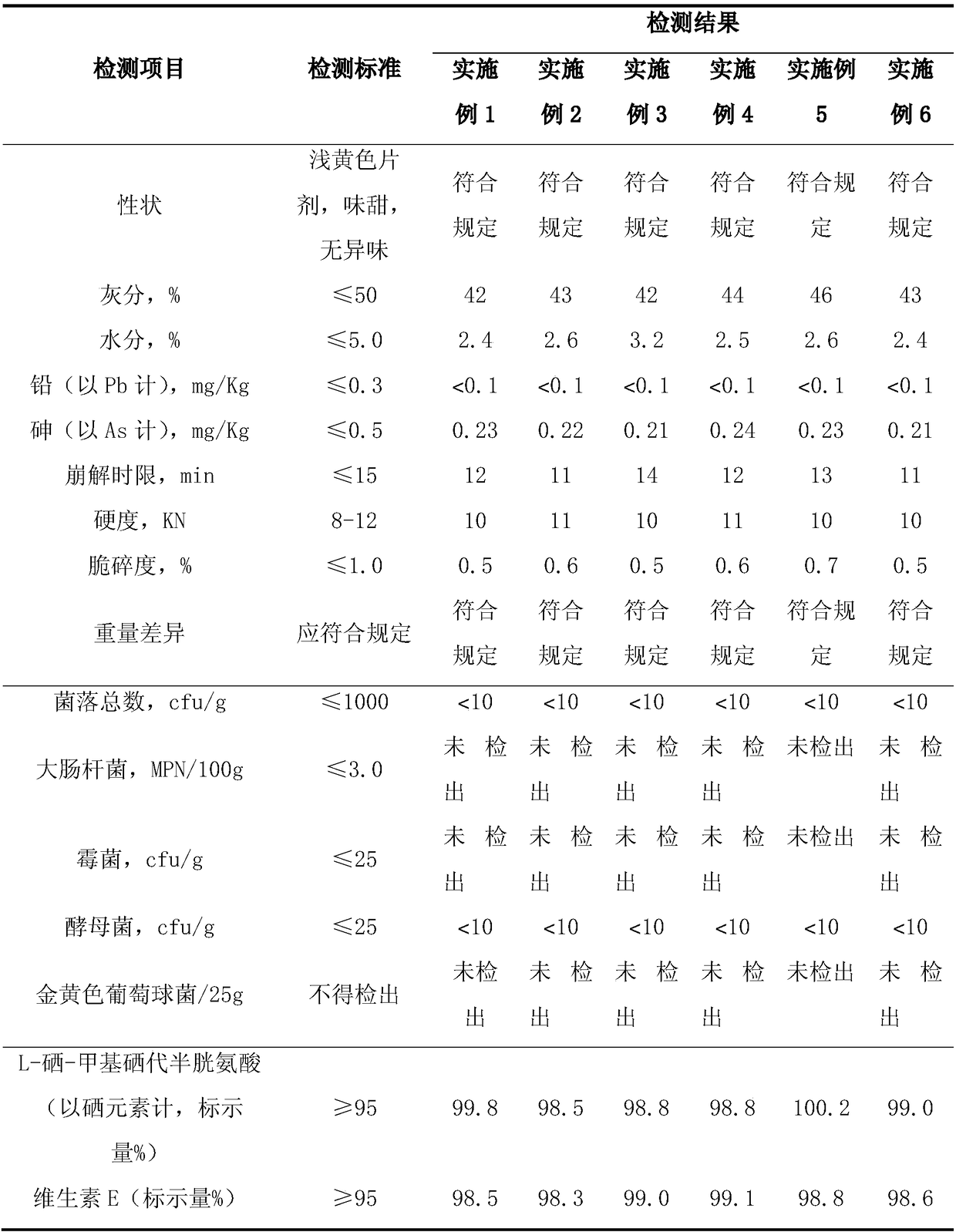

Examples

Embodiment 1

[0023] Grind L-selenium-methylselenocysteine, vitamin E microcapsules (50% content), microcrystalline cellulose, dextrin, and sugar powder in advance, and pass through a 60-mesh sieve; Selenocysteine, vitamin E microcapsules (50% content) are mixed according to the mass ratio of 0.035:15, then add microcrystalline cellulose that mass ratio is 5:5:10: dextrin: powdered sugar mixes, and then Add 7.5% PVP aqueous solution with a mass ratio of 1 and stir evenly to prepare a soft material (the degree to which the prepared soft material can be held tightly with hands can be formed into agglomerates, and can be cracked by pressing with fingers); the prepared soft material is passed through a 14-mesh sieve Net granulation, and then drying in a vacuum oven at 40°C, the moisture content is controlled at 2%, and then passing through a 18-mesh sieve to remove broken parts. The granules that will make, add the magnesium stearate that mass ratio is 0.1:0.1: Talcum powder, fully mix, then be...

Embodiment 2

[0025] Grind L-selenium-methylselenocysteine, vitamin E microcapsules (50% content), microcrystalline cellulose, dextrin, and sugar powder in advance, and pass through a 100-mesh sieve; L-selenium-methylselenocysteine Selenocysteine, vitamin E microcapsules (50% content) are mixed according to the mass ratio of 0.005:5, then add microcrystalline cellulose that mass ratio is 15:25:25: dextrin: powdered sugar mixes, and then Add a 7.5% PVP aqueous solution with a mass ratio of 3 and stir evenly to prepare a soft material (the degree to which the prepared soft material reaches is that it can form agglomerates when held tightly by hand, and can be split by pressing with fingers); the prepared soft material is passed through a 20-mesh sieve Net granulation, then drying in a vacuum drying oven at 65°C, the moisture content is controlled at 8%, and then passing through a 24-mesh sieve to remove broken parts. The granules that will make, add the magnesium stearate that mass ratio is 1...

Embodiment 3

[0027] Grind L-selenium-methylselenocysteine, vitamin E microcapsules (50% content), microcrystalline cellulose, dextrin, and sugar powder in advance, and pass through an 80-mesh sieve; L-selenium-methylselenocysteine Selenocysteine, vitamin E microcapsules (50% content) are mixed according to the mass ratio of 0.010:10, then add microcrystalline cellulose that mass ratio is 10:20:20: dextrin: powdered sugar mixes, and then Add a 7.5% PVP aqueous solution with a mass ratio of 2 and stir evenly to prepare a soft material (the degree to which the prepared soft material reaches is that it can form agglomerates when held tightly by hand, and can be split by pressing with fingers); the prepared soft material is passed through a 18-mesh sieve Net granulation, then drying in a vacuum drying oven at 50°C, the moisture content is controlled at 6%, and then passing through a 20-mesh sieve to remove broken parts. The granules that will make, add the magnesium stearate that mass ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com