Systems and methods for producing superabsorbent polymers

A manufacturing system, superabsorbent technology, applied in the field of superabsorbent polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description sets forth exemplary methods, parameters, etc. It should be appreciated, however, that the description is not intended as a limitation on the scope of the invention, but rather is provided as a description of illustrative embodiments.

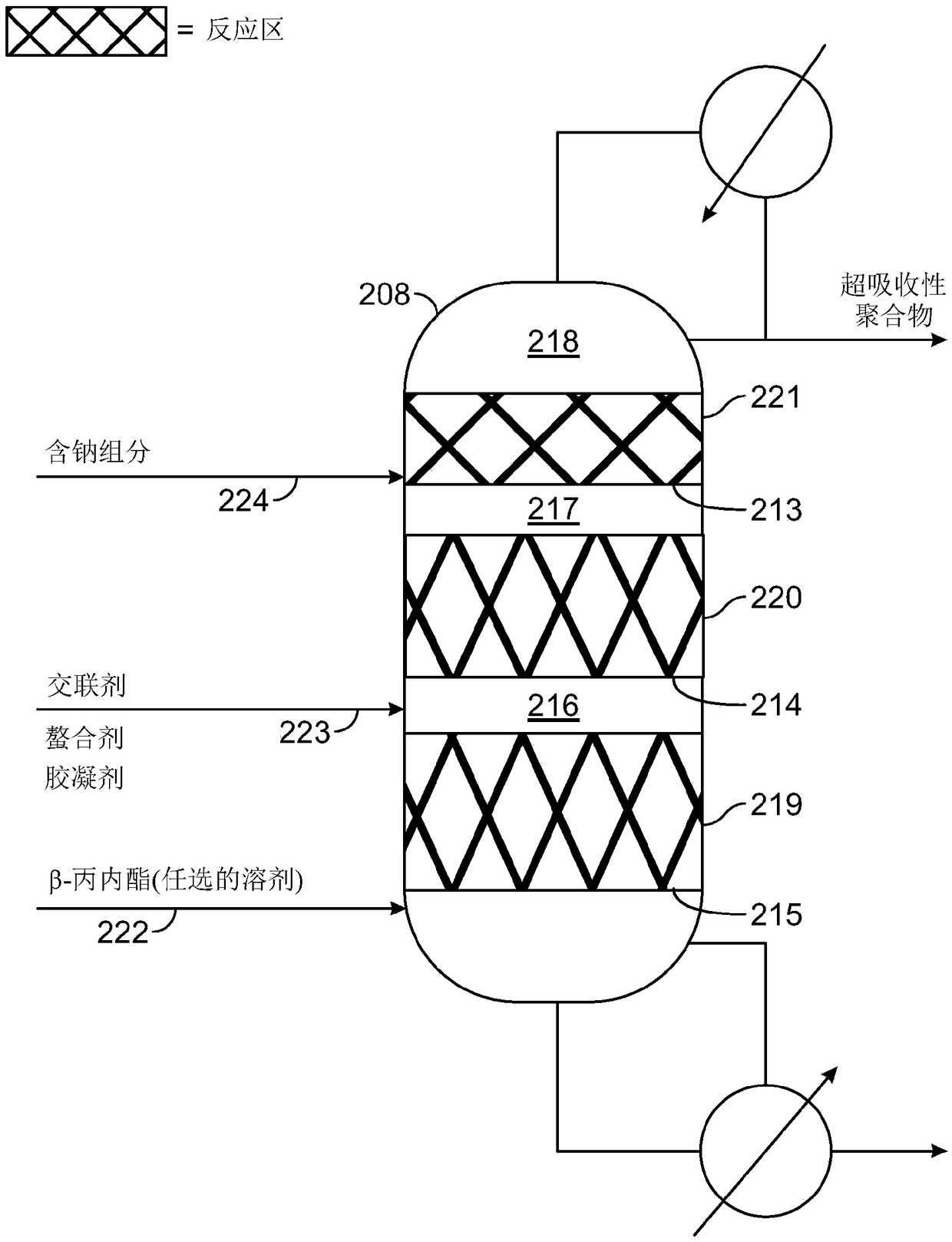

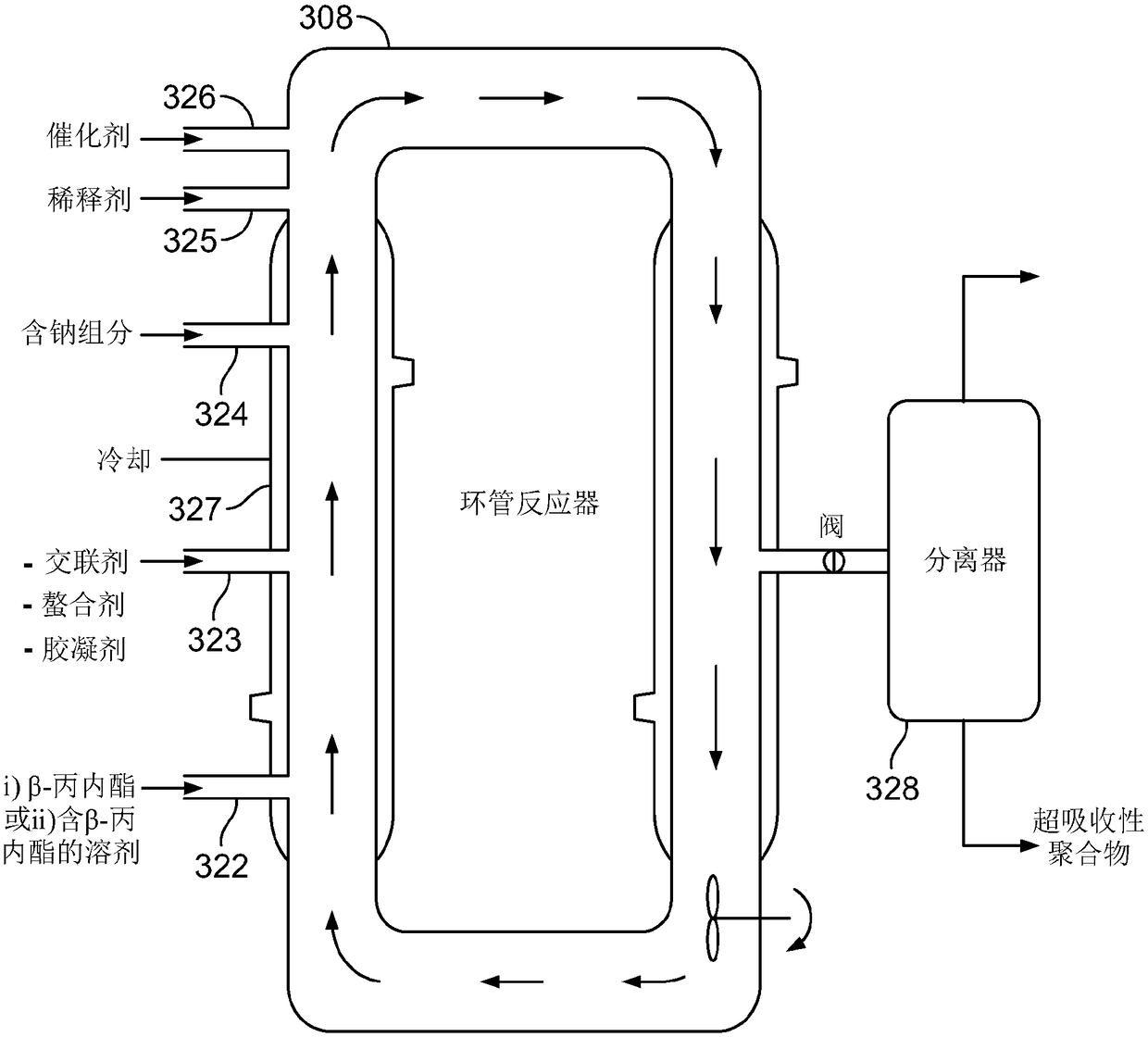

[0022] Provided herein are systems and methods for making superabsorbent polymers ("SAPs") from beta-propiolactone ("BPL"). For example, ethylene oxide ("EO") can be carbonylated, for example, with carbon monoxide ("CO") in the presence of a carbonylation catalyst to produce BPL. BPL can be polymerized in the presence of a polymerization catalyst to produce polypropiolactone ("PPL"). In addition, PPL can be thermally decomposed to produce acrylic acid "AA", including, for example, glacial acrylic acid "GAA". BPL, PPL, AA or combinations thereof can be used to make SAP.

[0023] refer to figure 1 , depicting an exemplary system for making SAP from carbon monoxide and ethylene oxide. Carbon monoxide ("CO") s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com