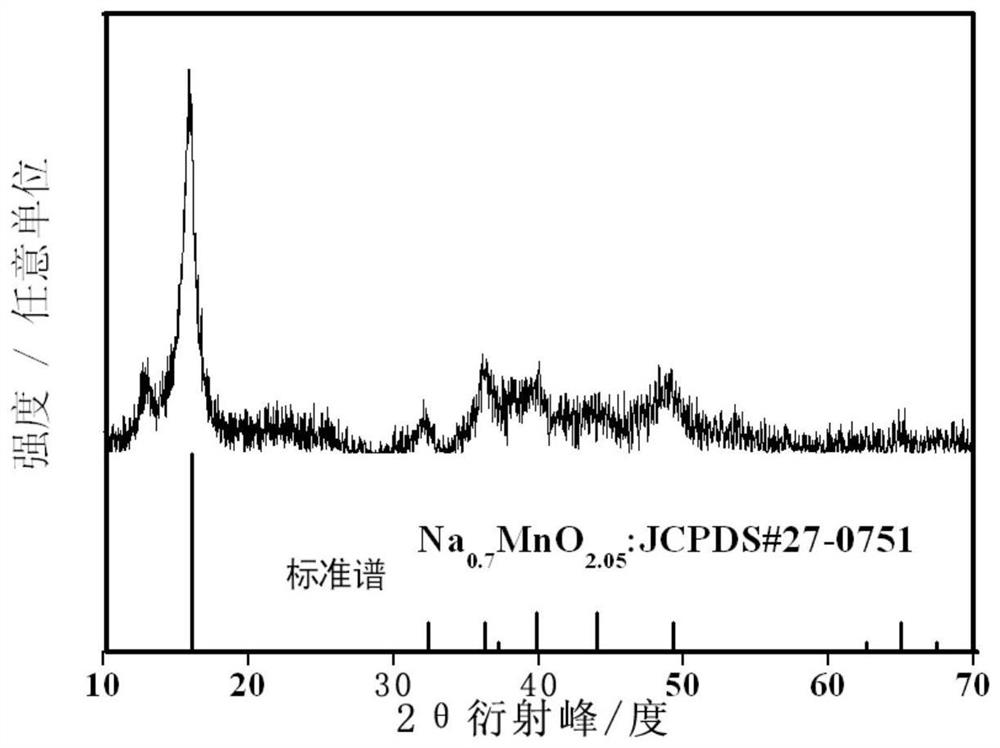

A kind of sodium manganate/graphene composite electrode material and its preparation method and application

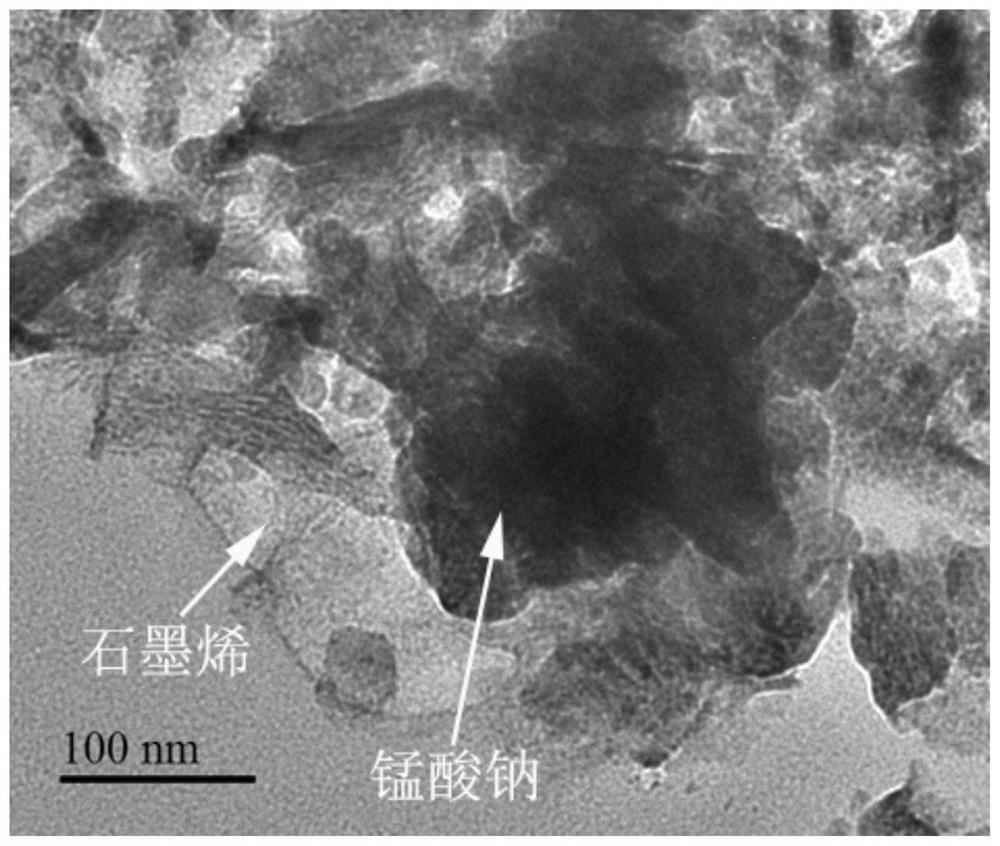

A graphene composite and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory cycle performance and low oxide activity, and achieve the improvement of electrochemical activity, reduction of side reactions, and prevention of dissolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

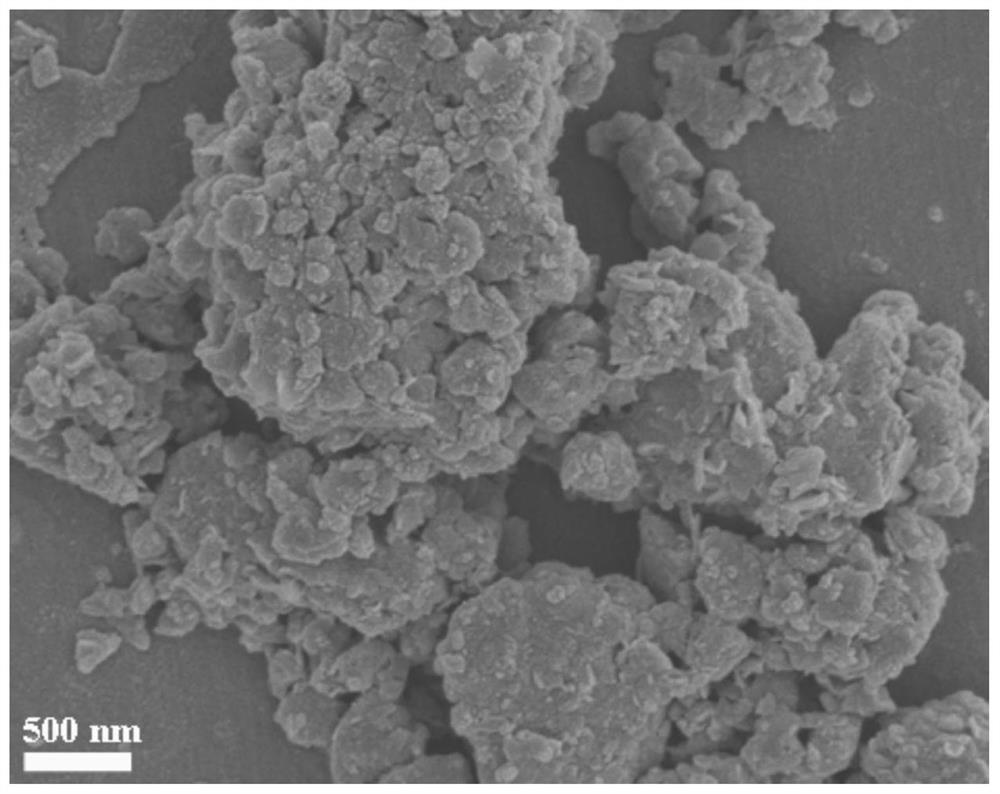

[0031] Press Na 0.7 MnO 2 f 0.05 The target product, the stoichiometric ratio of MnO 2 , NaF and Na 2 CO 3 (Na 2 CO 3 Excessive 2.5%) through dry vibration ball milling for 60 minutes, the vibration frequency is 20Hz, and then the powder is pressed into a block under a pressure of 2MPa; The heating rate was raised to 500°C, and pre-fired at 500°C for 5 hours, and then cooled to room temperature with the furnace; after the preliminary grinding of the pre-calcined product obtained above, the second vibration ball milling was carried out for 60 minutes, the vibration frequency was 20Hz, and then Press the powder into a block under pressure; place the pre-fired block above in a tube furnace, raise the temperature to 850°C at a heating rate of 5°C / min in an air atmosphere, and burn at 850°C for 12 hours, then Cool to room temperature with the furnace; mix the above-mentioned graphene and fluorine-doped sodium manganate particles at a weight ratio of 1:10, and perform the thi...

Embodiment 2

[0043] Press Na 0.7 MnO 1.95 f 0.1 The target product, the stoichiometric ratio of MnO 2 , NaF and Na 2 CO 3 (Na 2 CO 3 Excessive 2.5%) through dry vibration ball milling for 60 minutes, the vibration frequency is 20Hz, and then the powder is pressed into a block under a pressure of 2MPa; The heating rate was raised to 500°C, and pre-fired at 500°C for 5 hours, and then cooled to room temperature with the furnace; after the preliminary grinding of the pre-calcined product obtained above, the second vibration ball milling was carried out for 60 minutes, the vibration frequency was 20Hz, and then Press the powder into a block under pressure; put the above-mentioned pre-calcined block in a tube furnace, raise the temperature to 800°C at a heating rate of 5°C / min in an air atmosphere, and burn at 800°C for 15 hours, then Cool to room temperature with the furnace; mix the above-mentioned graphene and fluorine-doped sodium manganate particles at a weight ratio of 1:8, and per...

Embodiment 3

[0045] Press Na 0.7 MnO 1.90 f 0.15 The target product, the stoichiometric ratio of MnO 2 , NaF and Na 2 CO 3 (Na 2 CO 3 Excessive 2.5%) through dry vibration ball milling for 60 minutes, the vibration frequency is 20Hz, and then the powder is pressed into a block under a pressure of 2MPa; The heating rate was raised to 500°C, and pre-fired at 500°C for 5 hours, and then cooled to room temperature with the furnace; after the preliminary grinding of the pre-calcined product obtained above, the second vibration ball milling was carried out for 60 minutes, the vibration frequency was 20Hz, and then Press the powder into a block under pressure; put the above-mentioned pre-calcined block in a tube furnace, raise the temperature to 900°C at a heating rate of 5°C / min in an air atmosphere, and burn at 900°C for 10 hours, then Cool to room temperature with the furnace; mix the above-mentioned graphene and fluorine-doped sodium manganate particles at a weight ratio of 1:12, perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com