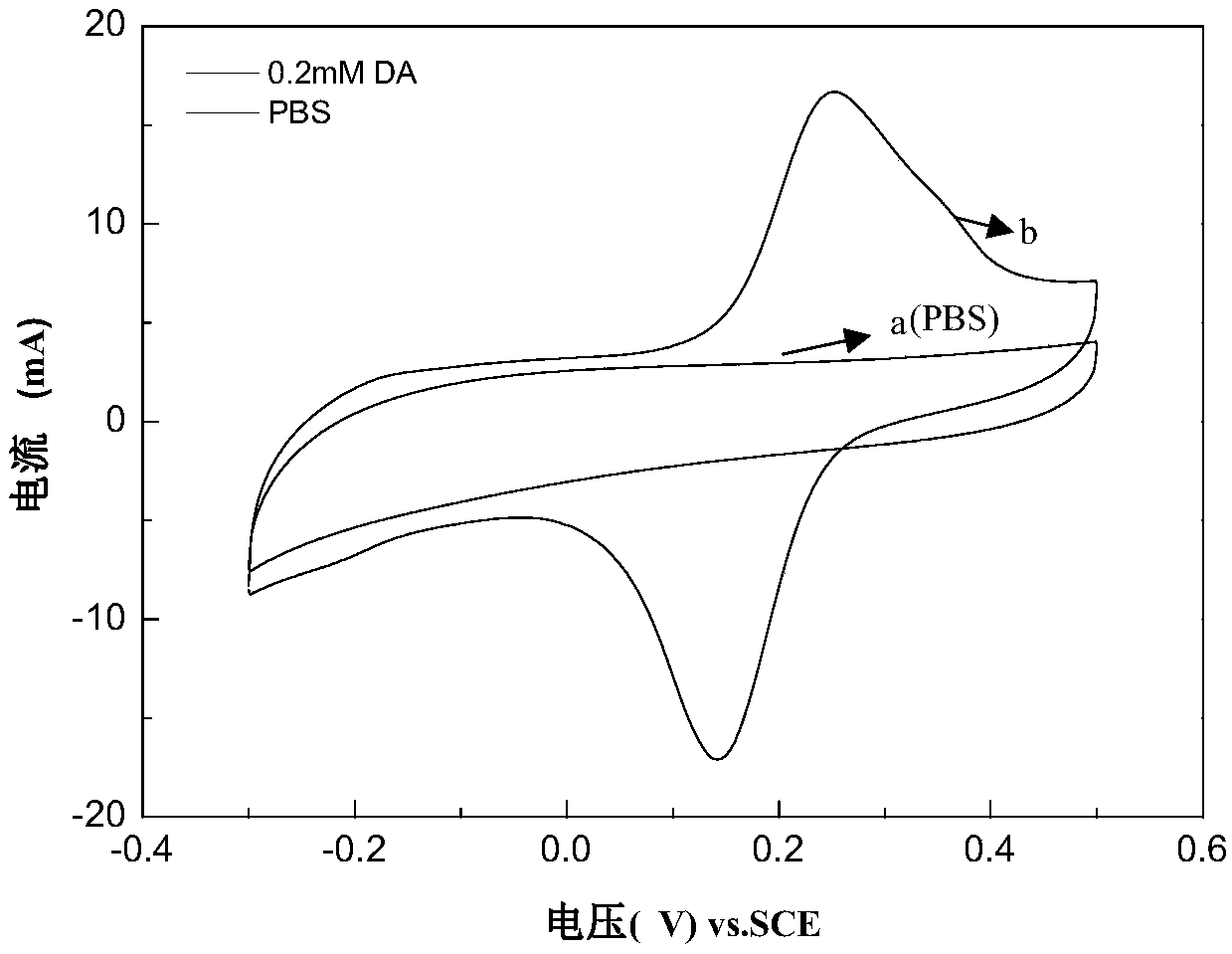

Dopamine sensor based on nitrogen doped graphene as well as preparation and application thereof

A technology of nitrogen-doped graphene and dopamine, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve problems affecting applications, high prices, and biological activity effects, and achieve low detection limits, simple preparation, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

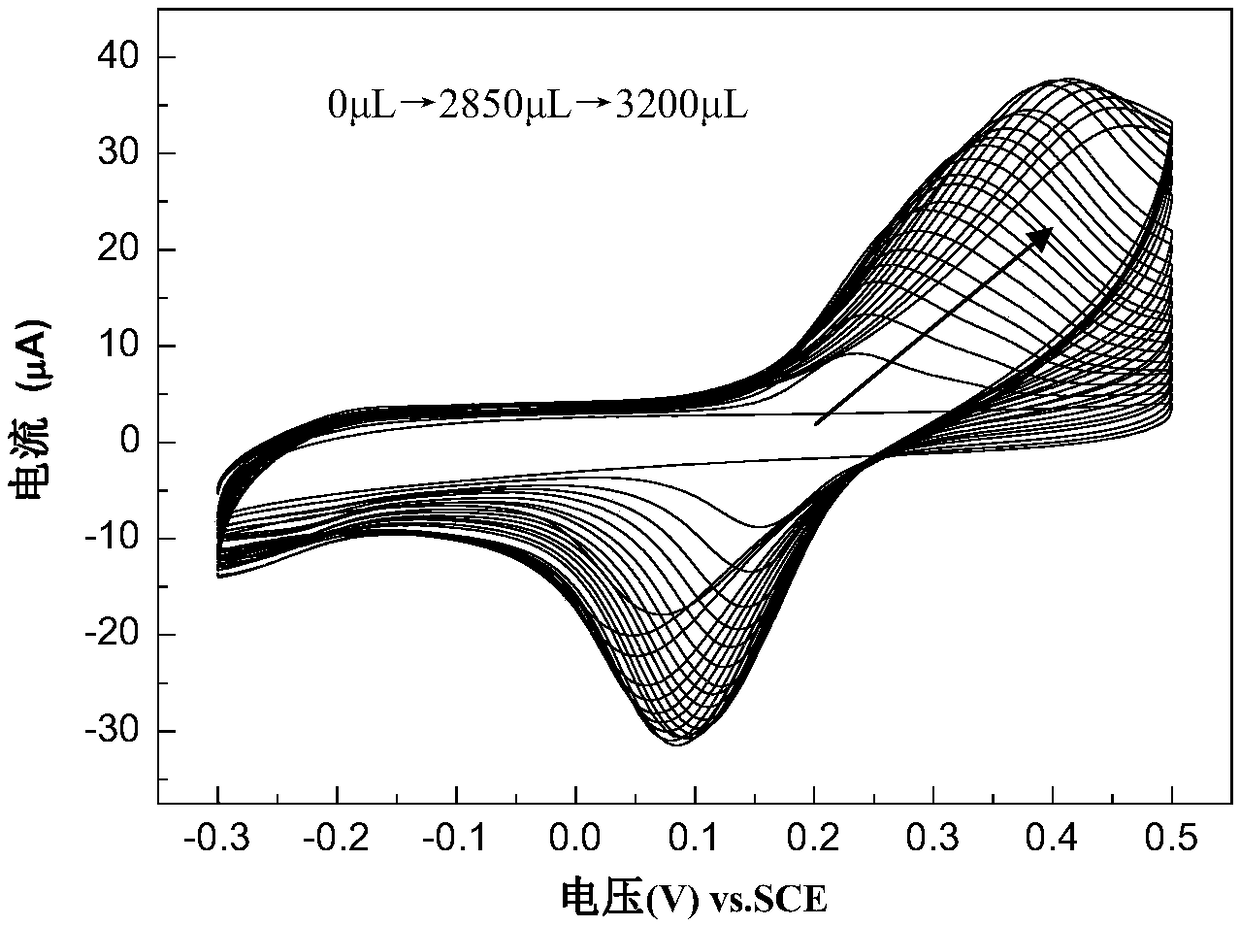

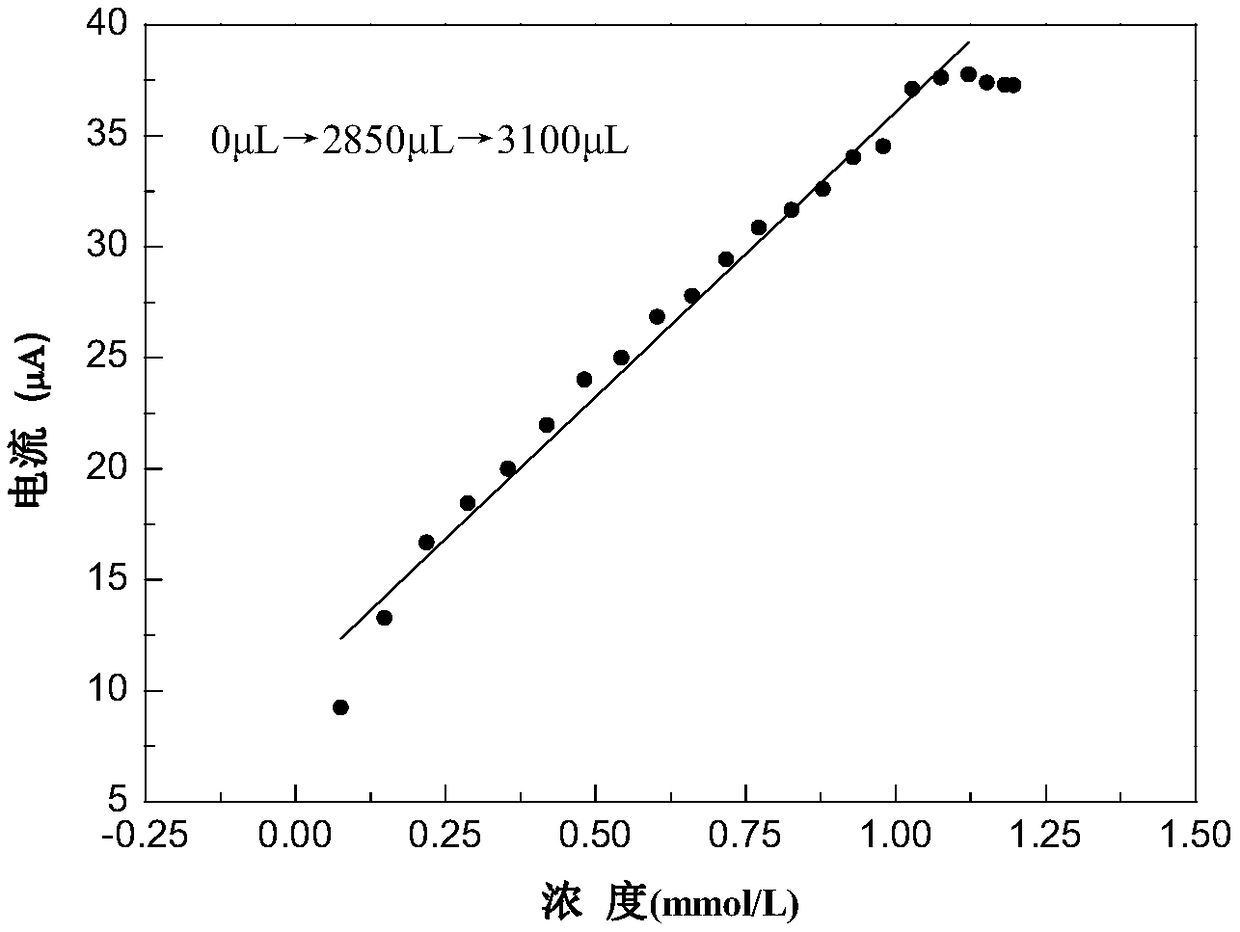

Examples

Embodiment 1

[0039] A preparation method of a dopamine sensor based on nitrogen-doped graphene, comprising the following steps:

[0040] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, taken out, rinsed with distilled water, and dried at room temperature to obtain a pretreated glassy carbon electrode;

[0041](2) Ultrasonically peel 100mg of graphene oxide in 50mL of deionized water for 4h (ultrasonic power is 100W), add 0.25mL of aniline, stir well and continue ultrasonication for 30min; under low temperature stirring (8°C), add 5mL containing 0.625g of ammonium persulfate (APS) 0.5M HCl (5mL of 0.5M HCl+0.625g ammonium persulfate), continue to stir at low temperature for 6 hours, then transfer to a hydrothermal reaction kettle, conduct a hydrothermal r...

Embodiment 2

[0047] A preparation method of a dopamine sensor based on nitrogen-doped graphene, comprising the following steps:

[0048] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, taken out, rinsed with distilled water, and dried at room temperature to obtain a pretreated glassy carbon electrode;

[0049] (2) Add 100 mg of graphene oxide into 50 mL of deionized water and ultrasonically peel for 4 hours, add 0.5 mL of aniline, stir evenly and continue ultrasonication for 30 min, add 5 mL of 0.5 M solution containing 1.25 g of ammonium persulfate (APS) under low temperature stirring (8°C). HCl, continue to stir at low temperature for 6 hours, then transfer to the reaction kettle, heat at 180°C for 16 hours, filter, wash with distilled water several ti...

Embodiment 3

[0058] A preparation method of a dopamine sensor based on nitrogen-doped graphene, comprising the following steps:

[0059] (1) The glassy carbon electrode with a diameter of 3 mm is sequentially filled with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water, and then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, taken out, rinsed with distilled water, and dried at room temperature to obtain a pretreated glassy carbon electrode;

[0060] (2) Add 100 mg of graphene oxide into 50 mL of deionized water for ultrasonic peeling for 4 h, add 1 mL of aniline, stir well and continue ultrasonication for 30 min, then add 5 mL of 0.5 M HCl containing 2.5 g of ammonium persulfate (APS) under low temperature stirring (8°C) , continue to stir at low temperature for 6 hours, then transfer to the reaction kettle, heat at 180°C for 16 hours, filter, wash with distilled water several times, dry in va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com