Production process of metal-based composite plate

A metal-based composite board and production process technology, applied in building materials, building components, buildings, etc., can solve the problems of inaccurate control of the curing reaction process, narrow use temperature range, long production line length, etc., to meet the requirements of the production process and Product quality, ensuring production process requirements, and improving the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

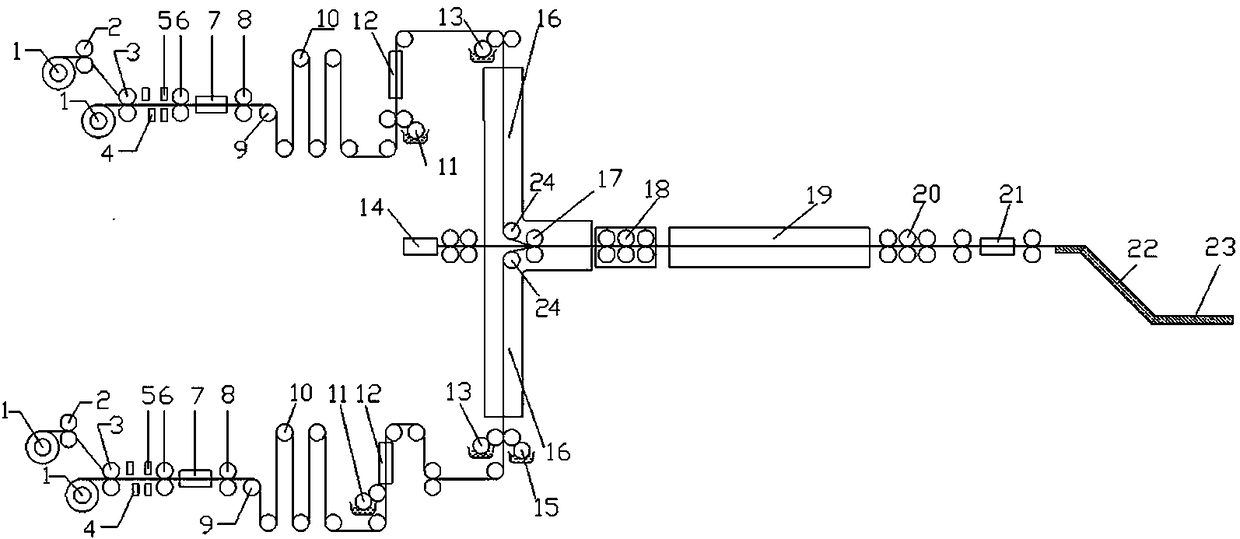

[0019] The stainless steel cold-rolled coil is uncoiled by the uncoiler 1, passes through the first pinch roll 2, the pinch flathead machine 3, and then repaired by the entrance shearing unit 4, occluded by the biting unit 5, and sent to the surface cleaning unit by the second pinch roll 6 7. Clean up the oil and dust on the surface. The cleaned metal strip enters the working range of the chemical coating machine 11 through the third pinch roller 8, the steering roller 9, and the entrance looper 10, and the chemical coating machine 11 coats the surface of the metal strip. A layer of chemical coating solution, after being dried by the chemical coating drying furnace 12, a layer of liquid polymer resin is coated on the lower surface and upper surface of the upper and lower metal strips by the respective coating machines 13 of the upper and lower layers. At the same time, the lower metal strip will be coated with a layer of liquid environmental protection paint on the lower surfac...

Embodiment 2

[0022] The stainless steel cold-rolled coil is uncoiled by the uncoiler 1, passes through the first pinch roll 2, the pinch flathead machine 3, and then repaired by the entrance shearing unit 4, occluded by the biting unit 5, and sent to the surface cleaning unit by the second pinch roll 6 7. Clean up the oil and dust on the surface. The cleaned metal strip enters the working range of the chemical coating machine 11 through the third pinch roller 8, the steering roller 9, and the entrance looper 10, and the chemical coating machine 11 coats the surface of the metal strip. A layer of chemical coating solution, after being dried by the chemical coating drying furnace 12, a layer of liquid polymer resin is coated on the lower surface and upper surface of the upper and lower metal strips by the respective coating machines 13 of the upper and lower layers. At the same time, the lower metal strip will be coated with a layer of liquid environmental protection paint on the lower surfac...

Embodiment 3

[0025] The stainless steel cold-rolled coil is uncoiled by the uncoiler 1, passes through the first pinch roll 2, the pinch flathead machine 3, and then repaired by the entrance shearing unit 4, occluded by the biting unit 5, and sent to the surface cleaning unit by the second pinch roll 6 7. Clean up the oil and dust on the surface. The cleaned metal strip enters the working range of the chemical coating machine 11 through the third pinch roller 8, the steering roller 9, and the entrance looper 10, and the chemical coating machine 11 coats the surface of the metal strip. A layer of chemical coating solution, after being dried by the chemical coating drying furnace 12, a layer of liquid polymer resin is coated on the lower surface and upper surface of the upper and lower metal strips by the respective coating machines 13 of the upper and lower layers. At the same time, the lower metal strip will be coated with a layer of liquid environmental protection paint on the lower surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com