Ultralow-temperature rolling preparation method for deformed Al-Mg alloy with ultrahigh Mg content

An ultra-low temperature and alloy technology, applied in the field of materials, can solve the problems that the porosity and porosity of the as-cast structure cannot be eliminated, damage the plasticity of the Al-Mg alloy, and the grains of the as-cast state cannot be refined, so as to achieve the accumulation and strengthening of dislocations. Grain boundary strengthening effect, effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

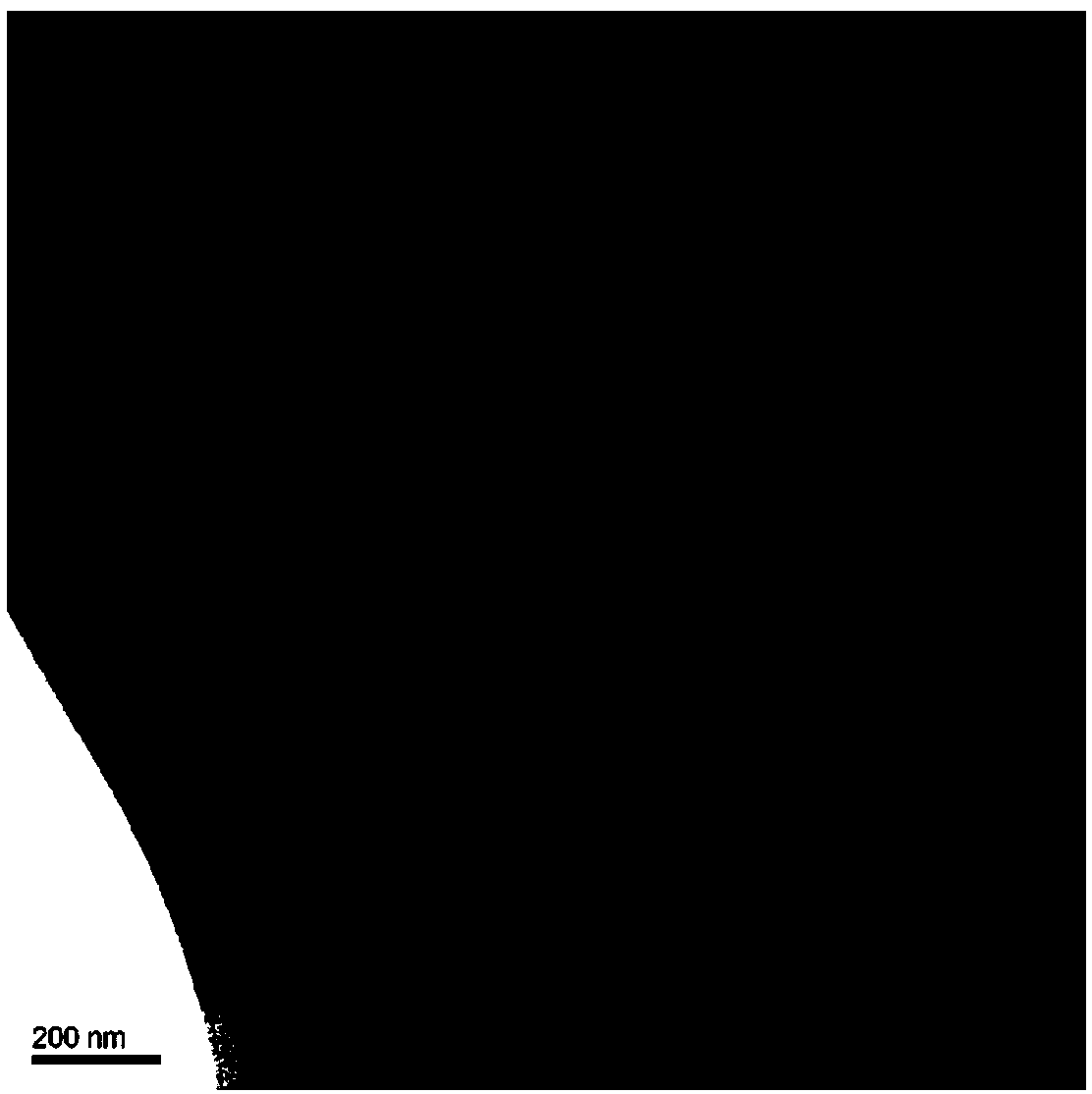

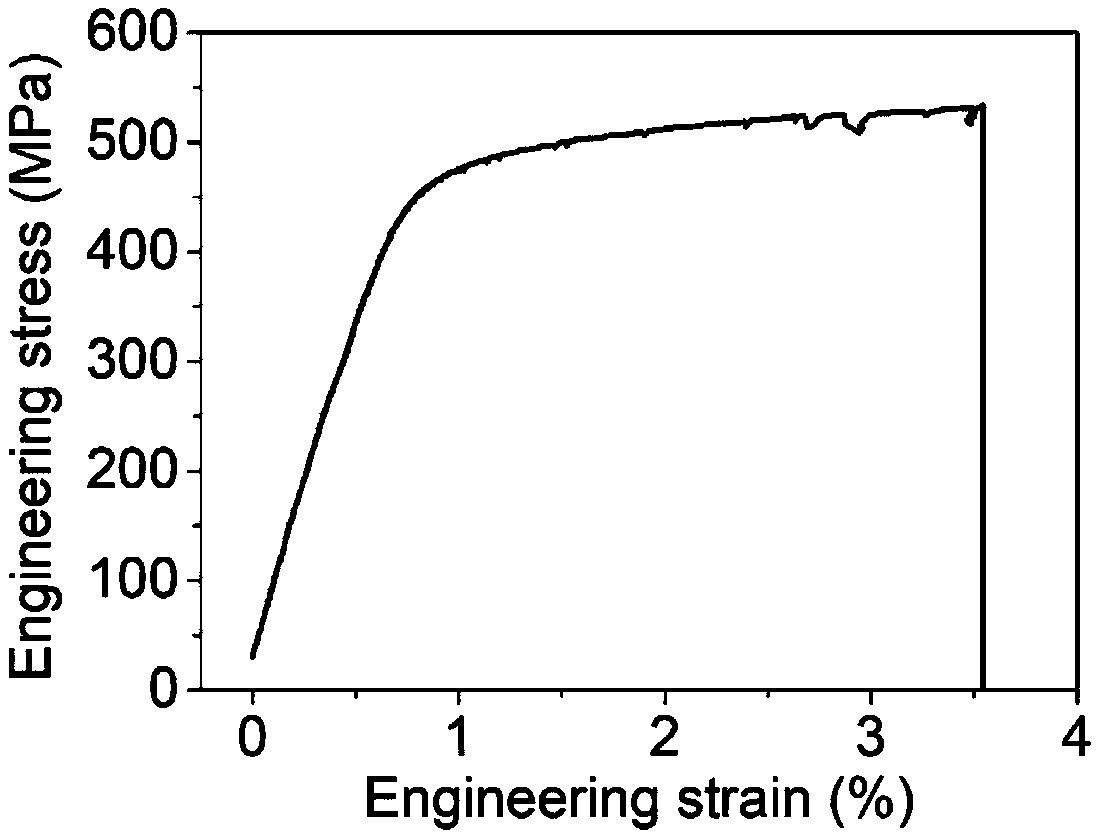

Embodiment 1

[0034] Add pure Mg and pure Al to a vacuum resistance melting furnace according to the mass percentage of Mg at 11% for smelting. Electromagnetic stirring makes the liquid Al-11wt.% Mg alloy (wt.% represents mass percentage) uniform in composition, and poured into the cast iron mold Obtained Al-11wt.% Mg alloy ingot. First, in a nitrogen protective atmosphere heating furnace, the ingot is heated to a temperature of 425°C, which is 80°C lower than the solidus temperature of the Al-11wt.%Mg alloy, 505°C. At this time, the Al-11wt.%Mg alloy is in a single-phase solid solution. State, keep it at this temperature for 8 hours, and homogenize the composition of the ingot. Next, the Al-11wt.%Mg alloy ingot with the homogenized composition was placed in a hot-pressing furnace protected by nitrogen, kept at 425°C and 75MPa for 2.5 hours, and then densified by hot pressing. Eliminate pores in cast alloys. Then, the Al-11wt.%Mg alloy that has been homogenized and densified in composition...

Embodiment 2

[0037] Add pure Mg and pure Al to a vacuum induction melting furnace according to 14% of the mass percentage of Mg for smelting. The electromagnetic stirring effect of the induction melting furnace itself makes the composition of the liquid Al-14wt.% Mg alloy uniform, and then it is poured into a cast iron mold. Al-14wt.% Mg alloy ingot. First, in a nitrogen protective atmosphere heating furnace, the ingot is heated to a temperature of 430°C which is 45°C lower than the solidus temperature of the Al-14wt.%Mg alloy at 475°C. At this time, the Al-14wt.%Mg alloy is in a single-phase solid solution. State, keep it at this temperature for 12 hours, and homogenize the composition of the ingot. Next, the Al-14wt.%Mg alloy ingot with the homogenized composition is subjected to hot extrusion at 430°C with an area shrinkage ratio of 6, to completely eliminate the pores in the cast alloy. Then, the Al-14wt.%Mg alloy that has been homogenized and densified in composition is reheated in a ...

Embodiment 3

[0040] Add pure Mg and pure Al to a vacuum induction melting furnace at 11% of the mass percentage of Mg for smelting. The electromagnetic stirring effect of the induction melting furnace makes the composition of the liquid Al-11wt.% Mg alloy uniform, and then it is poured into a cast iron mold. Al-11wt.% Mg alloy ingot. First, in a nitrogen protective atmosphere heating furnace, the ingot is heated to a temperature of 425°C, which is 80°C lower than the solidus temperature of the Al-11wt.%Mg alloy, 505°C. At this time, the Al-11wt.%Mg alloy is in a single-phase solid solution. State, keep it at this temperature for 8 hours, and homogenize the composition of the ingot. Next, the Al-11wt.%Mg alloy ingot with the homogenized composition is hot-rolled at 425°C to a total thickness reduction of 50% to completely eliminate the pores in the cast alloy. Then, the Al-11wt.%Mg alloy that has been homogenized and densified in composition is reheated in a nitrogen atmosphere heating furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com