A kind of high-strength high-plasticity high-entropy alloy and preparation method thereof

A technology of high-entropy alloy and high plasticity, which is applied in the field of high-entropy alloy and its preparation, can solve the problem of low strength, achieve the effect of improving strength and plasticity, promoting fine-grain strengthening, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Use fine sandpaper to remove the oxide scales on the surface of metal Co, Cr, Fe, Ni, and then use absolute ethanol to perform ultrasonic cleaning to obtain a clean metal block; weigh the total amount according to the molar ratio of 1:1:1:1 Mixed raw materials with a mass of 70g;

[0028] (2) Repeatedly smelting the weighed raw materials in a high-purity Ar gas environment in a high-vacuum arc melting furnace;

[0029] (3) The alloy melted in the step (2) is cast into an ingot at a temperature of 1000° C. for 12 hours, subjected to homogenization heat treatment, and then taken out of water and quenched to room temperature to obtain a homogenized state high-entropy alloy.

[0030] Experimental results:

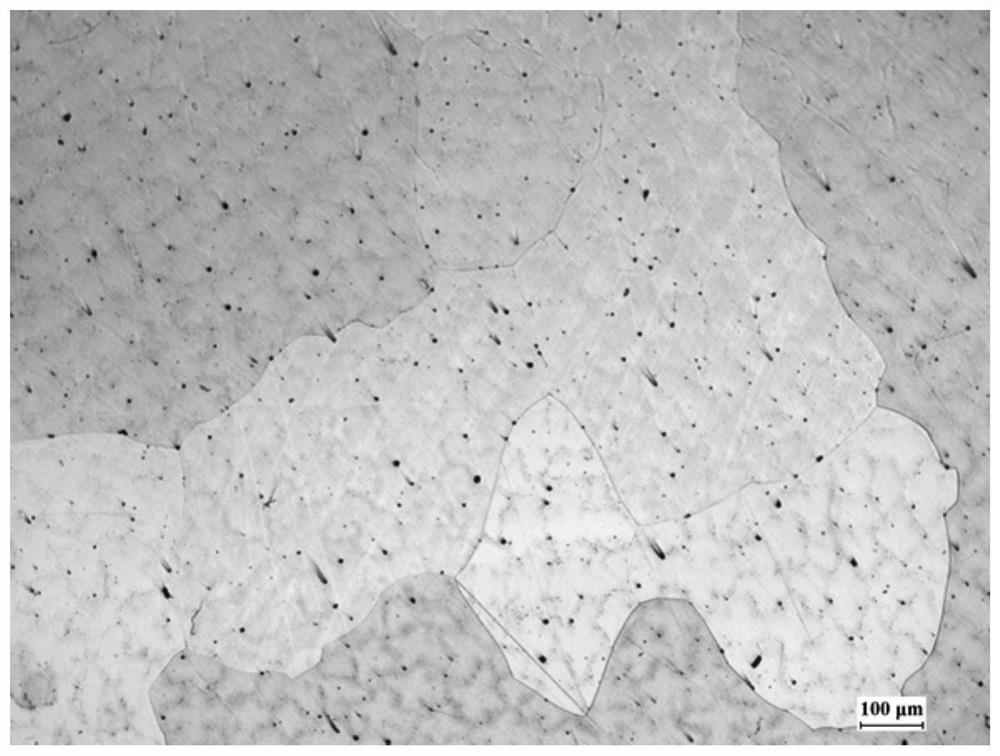

[0031] The high-entropy alloy prepared above was coarsely ground step by step with different types of sandpaper, finely ground to #1600, and then mechanically polished until there were no obvious scratches on the surface, and the alloy was corroded with a metallogra...

Embodiment 2

[0034] (1) Use fine sandpaper to remove the oxide skin on the surface of metal Co, Cr, Fe, Ni, Al-10Er, and then use absolute ethanol to perform ultrasonic cleaning to obtain a clean metal block; according to the molar ratio of 1:1:1:1 : 0.05 Weigh out the mixed raw material that total mass is 70g;

[0035] (2) Repeatedly smelting the weighed raw materials in a high-purity Ar gas environment in a high-vacuum arc melting furnace;

[0036] (3) The alloy melted in the step (2) is cast into an ingot at a temperature of 1000° C. for 12 hours, subjected to homogenization heat treatment, and then taken out of water and quenched to room temperature to obtain a homogenized state high-entropy alloy.

[0037] Experimental results:

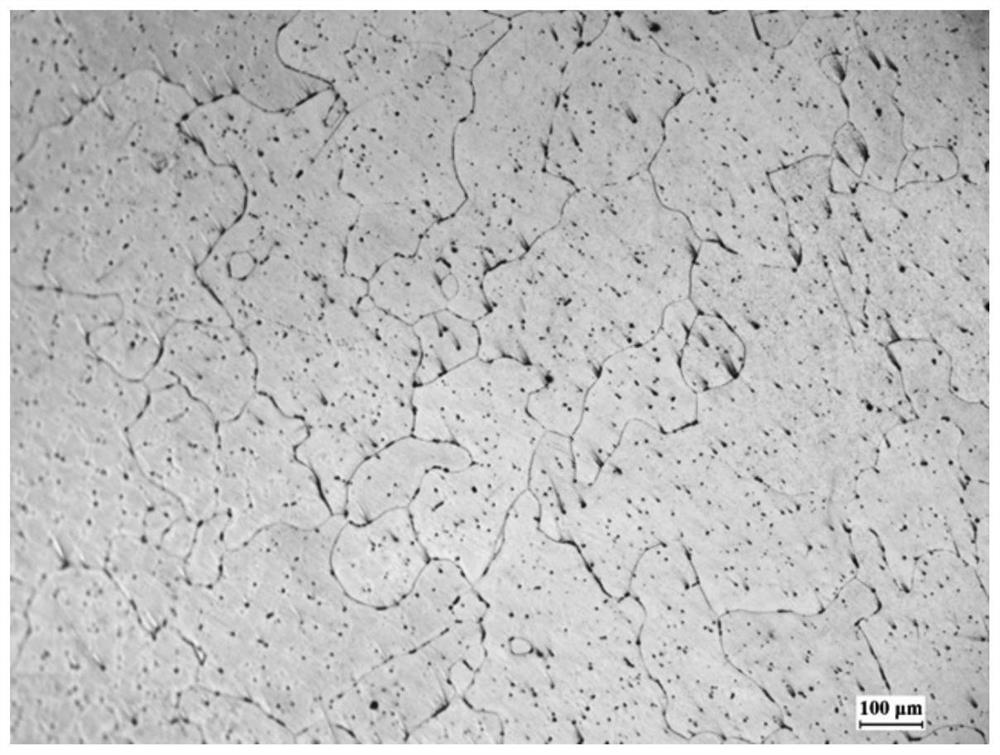

[0038] The high-entropy alloy prepared above was coarsely ground step by step with different types of sandpaper, finely ground to #1600, and then mechanically polished until there were no obvious scratches on the surface, and the alloy was corroded with a me...

Embodiment 3

[0041] A preparation method of a high-strength high-plastic high-entropy alloy, the specific steps are as follows:

[0042] (1) Use fine sandpaper to remove the oxide skin on the surface of metal Co, Cr, Fe, Ni, Al-10Er, and then use absolute ethanol to perform ultrasonic cleaning to obtain a clean metal block; according to the molar ratio of 1:1:1:1 : 0.05 Weigh out the mixed raw material that total mass is 70g;

[0043] (2) Repeatedly smelting the weighed raw materials in a high-purity Ar gas environment in a high-vacuum arc melting furnace;

[0044] (3) Casting the alloy melted in step (2) into an ingot at a temperature of 1000°C for 12 hours, performing a homogenization heat treatment, and then taking out the water and quenching to room temperature to obtain a homogenized state high-entropy alloy;

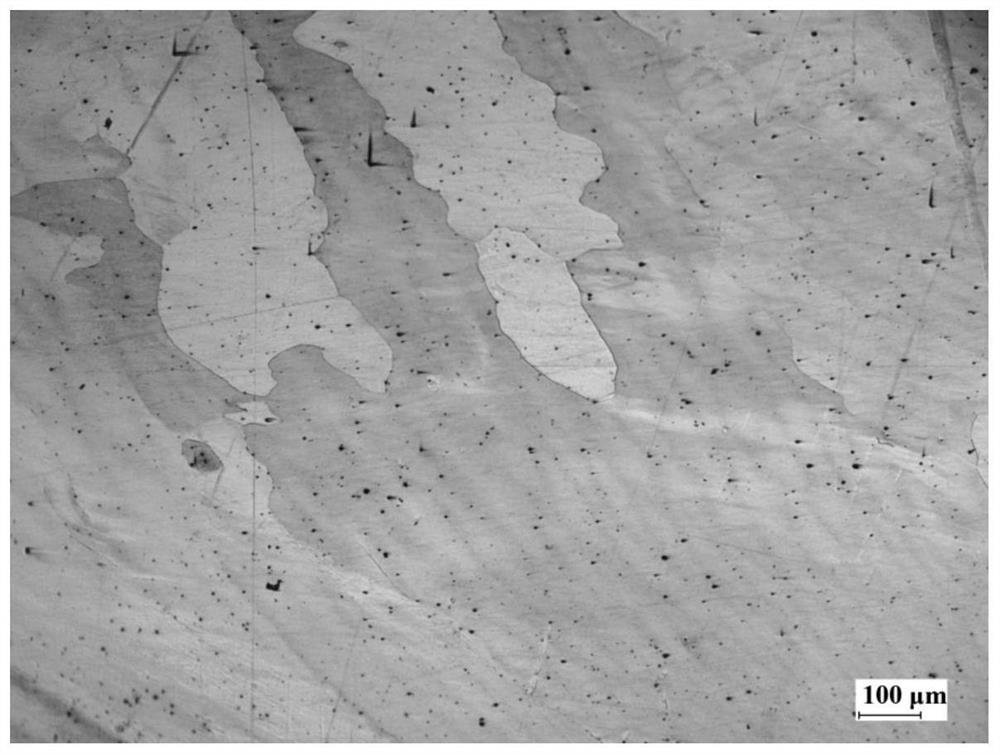

[0045] (4) Cut the homogenized heat-treated alloy ingot in step (3) into 16×16×4mm samples, and carry out 4 passes of rolling at 650°C, each time the reduction is 0.5mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com