Decontamination emulsion for hard surface cleaning and preparation method thereof,

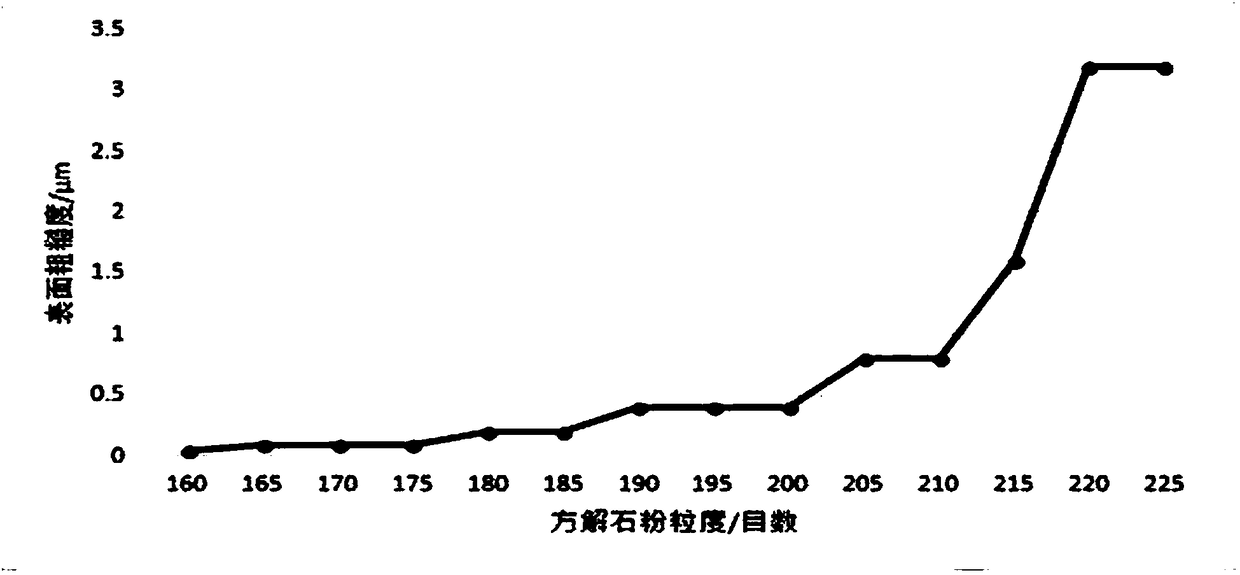

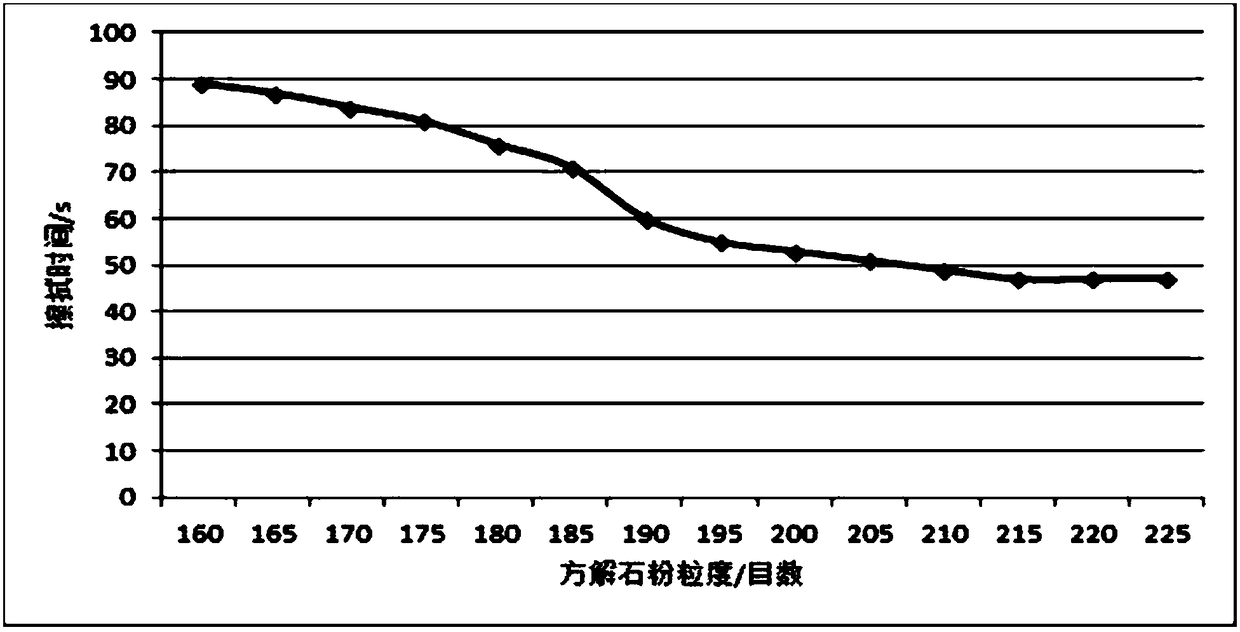

A hard surface and clean technology, applied in the field of detergent, can solve the problems of high transportation cost, hard hardness, large calcium carbonate particles, etc., and achieve the effect of reducing wear, moderate hardness, and good granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of decontamination emulsion that is used for hard surface cleaning adopts following method to obtain:

[0039] (1) Pre-mixing: Add 22.1kg deionized water into the batching kettle and heat to 90°C, then add 7kg sodium dodecylbenzenesulfonate, 7kg fatty alcohol polyoxyethylene ether, 0.18kg disodium edetate , 0.06kg sodium silicate, 0.06kg sodium gluconate and 30kg particle size are 200 mesh calcite powder, stirred for 15min at a rotating speed of 525r / min;

[0040] (2) Preparation: Add 0.3kg of isothiazolinone preservative, 1.2kg of urea with a nitrogen content of 46%, 7kg of glycerol polyoxyethylene ether, 1.4kg of ethanol, 0.93kg of triethanolamine, 0.47 kg chitosan, 0.2kg essence and 22.1kg deionized water were stirred at a speed of 250r / min for 55min, then abrasives were added and stirred at a speed of 350r / min for 75min to obtain a decontamination emulsion for hard surface cleaning.

Embodiment 2

[0041] Embodiment 2: a kind of decontamination emulsion that is used for hard surface cleaning adopts following method to obtain:

[0042] (1) Pre-mixing: Add 22.5kg deionized water into the batching kettle and heat to 85°C, then add 4kg sodium dodecylbenzenesulfonate, 4kg fatty alcohol polyoxyethylene ether, 0.06kg disodium edetate , 0.02kg sodium silicate, 0.02kg sodium gluconate and 20kg particle size are 200 mesh calcite powder, stirred for 20min at a rotating speed of 500r / min;

[0043] (2) Preparation: Add 0.1kg of isothiazolinone preservative, 0.9kg of urea with a nitrogen content of 46%, 4kg of glycerol polyoxyethylene ether, 0.9kg of ethanol, 1.27kg of triethanolamine, 0.63 kg chitosan, 0.1kg essence and 22.5kg deionized water were stirred at a speed of 200r / min for 60min, then abrasives were added and stirred at a speed of 300r / min for 60min to obtain a decontamination emulsion for hard surface cleaning.

Embodiment 3

[0044] Embodiment 3: a kind of decontamination emulsion that is used for hard surface cleaning adopts following method to obtain:

[0045] (1) Pre-mixing: add 22.4kg deionized water into the batching kettle and heat to 85°C, then add 10kg sodium dodecylbenzenesulfonate, 10kg fatty alcohol polyoxyethylene ether, 0.3kg disodium edetate , 0.1kg sodium silicate, 0.06kg sodium gluconate and 39kg particle size are 200 mesh calcite powder, stirred for 10min at a rotating speed of 550r / min;

[0046] (2) Preparation: Add 0.5kg of isothiazolinone preservative, 1.5kg of urea with a nitrogen content of 46%, 10kg of glycerol polyoxyethylene ether, 1.9kg of ethanol, 0.33kg of triethanolamine, 0.17 kg chitosan, 0.3kg essence and 22.4kg deionized water were stirred at a speed of 300r / min for 50min, then abrasives were added and stirred at a speed of 400r / min for 60min to obtain a decontamination emulsion for hard surface cleaning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com