Biomass charcoal bar with high calorific value

A biochar, high calorific value technology, applied in the direction of biofuel, waste fuel, solid fuel, etc., can solve the problems affecting people's life, traffic accidents, air pollution, etc., to reduce slagging corrosion, strong anti-slagging ability, The effect of less ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

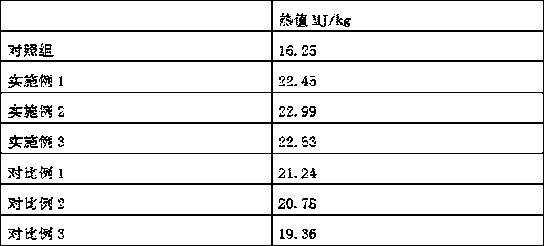

Examples

Embodiment 1

[0017] A kind of high calorific value biomass charcoal rod, after crushing corn stalks, corn stalk powder is obtained, and then the corn stalk powder is treated with a silane coupling agent solution, and then the treated corn stalk powder is modified by a copolymer , and then carbonized in a pyrolysis furnace to obtain biomass charcoal, and then press the biomass charcoal to obtain carbon rods.

[0018] Further, the particle size of the corn stalk powder is 50 mesh.

[0019] Further, the corn stalk powder is treated with a silane coupling agent solution as follows: the corn stalks are soaked in a 70°C water bath for 2 hours with a 5.5% mass fraction of an organosilane coupling agent solution, then filtered, and dried to a constant weight , you can.

[0020] Further, the preparation method of the copolymer is:

[0021] Add tetraethyl orthosilicate and ethanol into the reaction kettle at a mass ratio of 12:3.3, stir at a speed of 500r / min, and then add deionized water dropwise...

Embodiment 2

[0028] A kind of high calorific value biomass charcoal rod, after crushing corn stalks, corn stalk powder is obtained, and then the corn stalk powder is treated with a silane coupling agent solution, and then the treated corn stalk powder is modified by a copolymer , and then carbonized in a pyrolysis furnace to obtain biomass charcoal, and then press the biomass charcoal to obtain carbon rods.

[0029] Further, the particle size of the corn stalk powder is 50 mesh.

[0030] Further, the corn stalk powder is treated with a silane coupling agent solution as follows: the corn stalks are soaked in a 70°C water bath for 2 hours with a 5.5% mass fraction of an organosilane coupling agent solution, then filtered, and dried to a constant weight , you can.

[0031] Further, the preparation method of the copolymer is:

[0032] Add tetraethyl orthosilicate and ethanol into the reaction kettle at a mass ratio of 12:3.3, stir at a speed of 500r / min, and then add deionized water dropwise...

Embodiment 3

[0039] A kind of high calorific value biomass charcoal rod, after crushing corn stalks, corn stalk powder is obtained, and then the corn stalk powder is treated with a silane coupling agent solution, and then the treated corn stalk powder is modified by a copolymer , and then carbonized in a pyrolysis furnace to obtain biomass charcoal, and then press the biomass charcoal to obtain carbon rods.

[0040] Further, the particle size of the corn stalk powder is 50 mesh.

[0041] Further, the corn stalk powder is treated with a silane coupling agent solution as follows: the corn stalks are soaked in a 70°C water bath for 2 hours with a 5.5% mass fraction of an organosilane coupling agent solution, then filtered, and dried to a constant weight , you can.

[0042] Further, the preparation method of the copolymer is:

[0043]Add tetraethyl orthosilicate and ethanol into the reaction kettle at a mass ratio of 12:3.3, stir at a speed of 500r / min, and then add deionized water dropwise....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com