Diene open-loop process control system and application system thereof

A process control and metering tank technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of unstable side reactions and low diene yields, and achieve the effects of safe reactions, complete reactions, and reduced human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

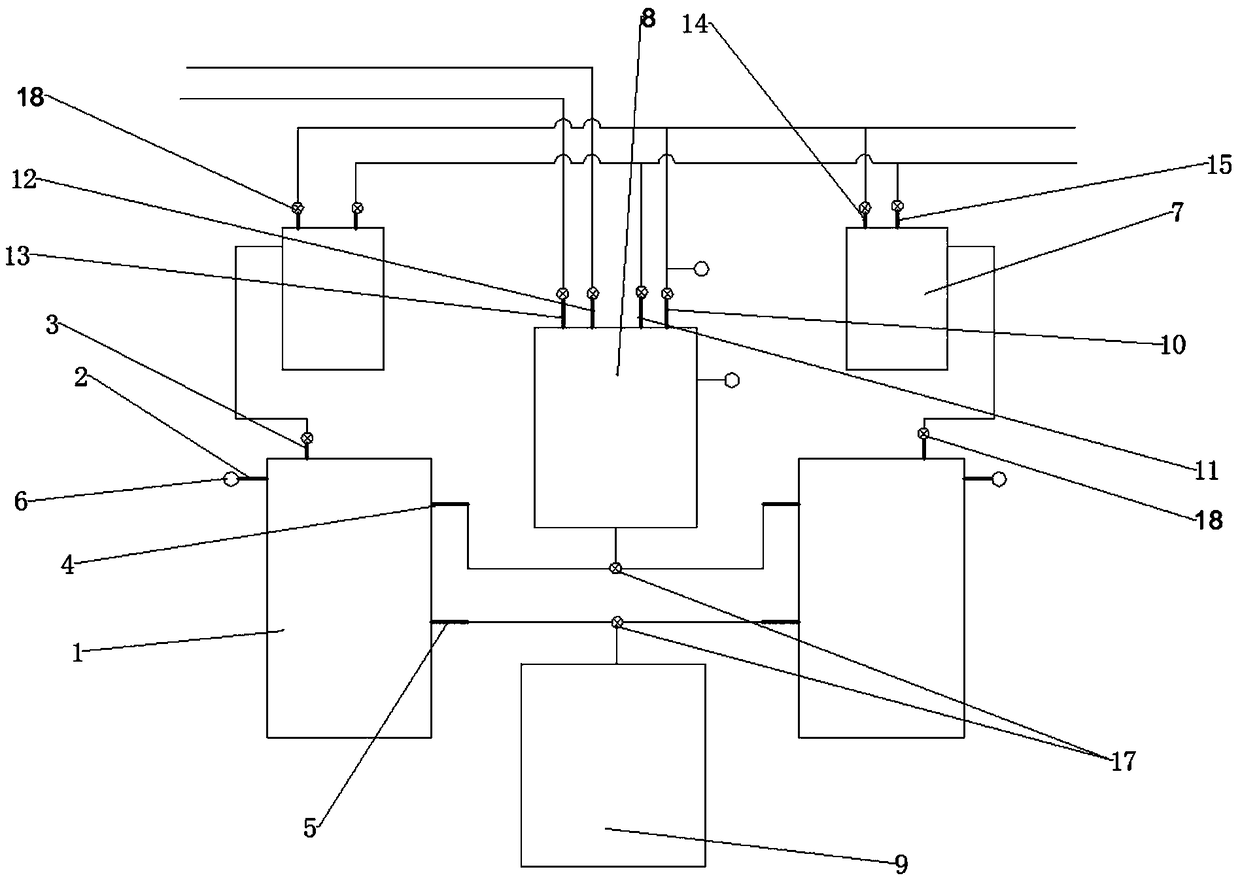

[0056] Such as Figure 1~4 , the present embodiment proposes a diene ring-opening process control system, including a first raw material tank (not shown) and a second raw material tank (not shown), the first raw material tank is stored with acid anhydride, and the second raw material tank stored in glacial acetic acid,

[0057] It also includes two open-loop tanks 1, and each open-loop tank 1 is provided with a first connecting pipe 2, a second connecting pipe 3, a third connecting pipe 4 and a fourth connecting pipe 5, wherein the two first connecting pipes 2 are respectively connected with meters 6, The two second connecting pipes 3 are jointly connected to a buffer tank 7, the two third connecting pipes 4 are connected to a metering tank 8 after converging, and the two fourth connecting pipes are connected to an oxidation tank 9 after converging, and the oxidation tank 9 is used for oxidation and hydrolysis reactions ;

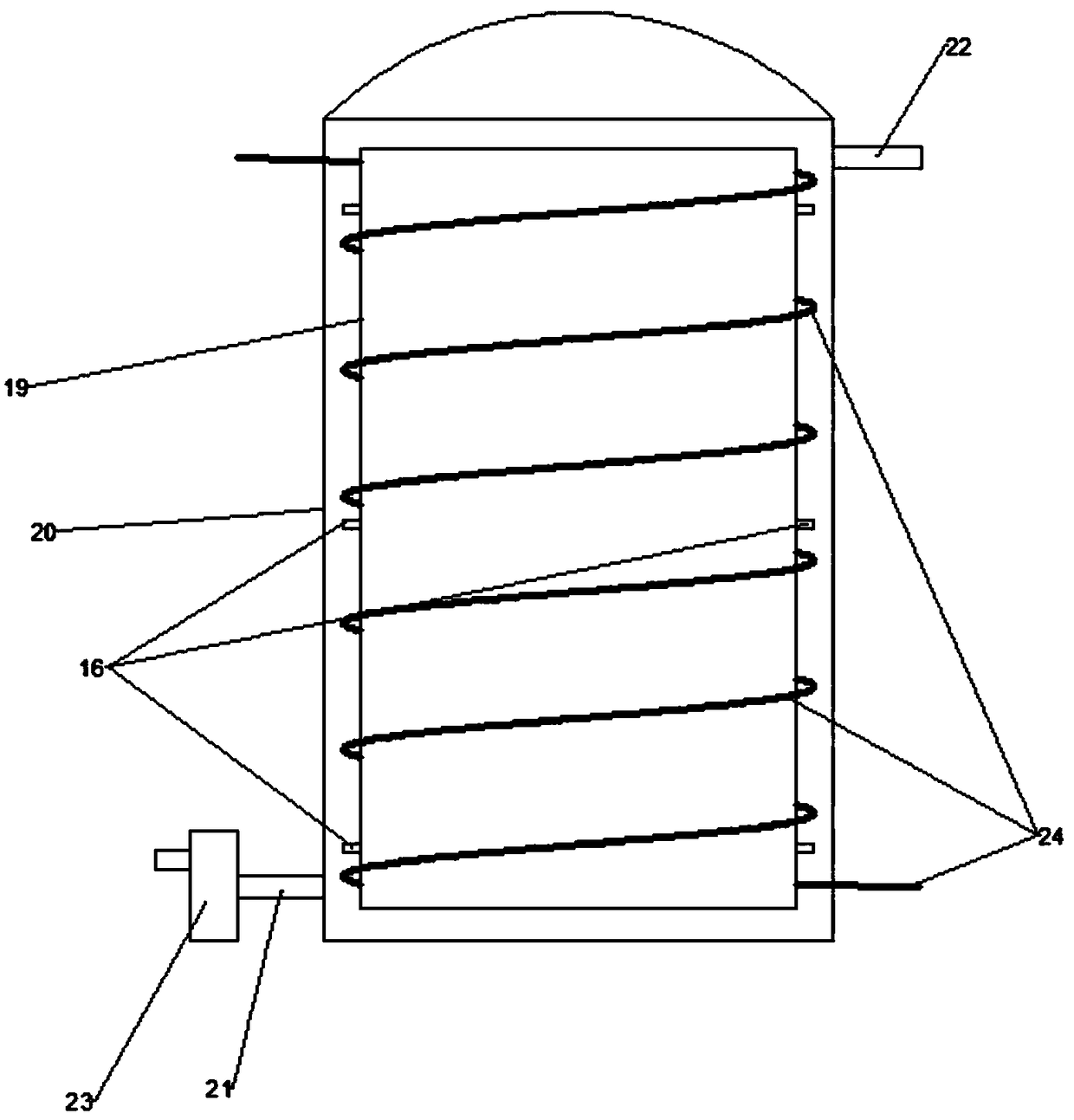

[0058] The metering tank 8 is provided with the fif...

Embodiment 2

[0089] The present embodiment except the following content, all the other parts are identical with embodiment 1; The difference is:

[0090] A method for using a diene ring-opening process control system, comprising the following steps:

[0091] S1 Add diosgenin to the two open-loop tanks 1, adjust the pressure of the metering tank 8 to -0.06Mpa, connect the metering tank 8 and the first raw material tank, and disconnect the metering tank 8 and the first raw material tank when the liquid level of the metering tank 8 shows 80%. Raw material tank;

[0092] S2 adjust the pressure of any open-loop tank 1 to -0.08Mpa, connect the open-loop tank 1 and the metering tank 8, when the liquid level of the metering tank 8 shows 2%, disconnect the open-loop tank 1 and the metering tank 8;

[0093] S3 adjusts the pressure of the metering tank 8 to -0.06Mpa, connects the metering tank 8 and the second raw material tank, and when the liquid level of the metering tank 8 shows 30%, disconnects...

Embodiment 3

[0102] The present embodiment except the following content, all the other parts are identical with embodiment 1; The difference is:

[0103] A method for using a diene ring-opening process control system, comprising the following steps:

[0104] Add diosgenin into two open-loop tanks 1 of S1, adjust the pressure of the metering tank 8 to -0.05Mpa, connect the metering tank 8 and the first raw material tank, and when the liquid level of the metering tank 8 shows 85%, disconnect the metering tank 8 and the first raw material tank. Raw material tank;

[0105] S2 adjusts the pressure of any open-loop tank 1 to -0.07Mpa, connects the open-loop tank 1 and the metering tank 8, and disconnects the open-loop tank 1 and the metering tank 8 when the liquid level of the metering tank 8 shows 5%;

[0106] S3 adjusts the pressure of the metering tank 8 to -0.05Mpa, connects the metering tank 8 and the second raw material tank, and when the liquid level of the metering tank 8 shows 35%, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com