Concrete crack repairing material based on phosphorus magnesium material and construction technology thereof

A technology of crack repair and construction technology, applied in the field of concrete repair, which can solve the problems of low bond strength between old and new materials, unsuitable resin infusion method, and weakened overall performance of the structure, so as to achieve low dry shrinkage and high flexural strength , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

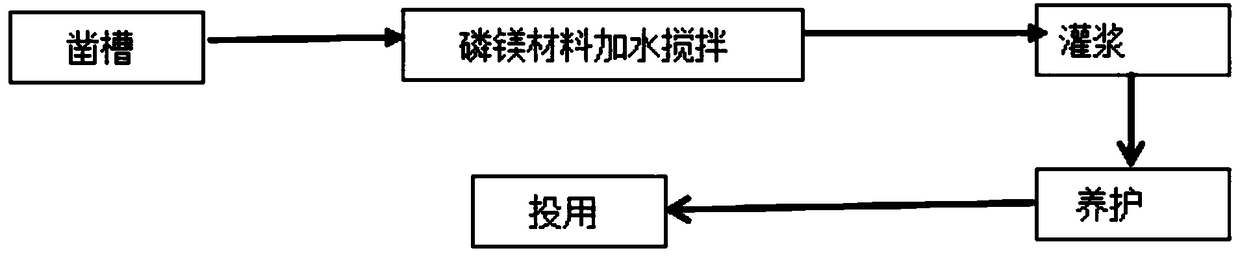

[0086] (1) Grooving: use a concrete wall slotting machine to chisel grooves along the cracks on the cracked concrete structure surface, the groove width is 35mm, the depth is 40mm, the shape is V-shaped, and the grooves are cleaned with high-pressure air;

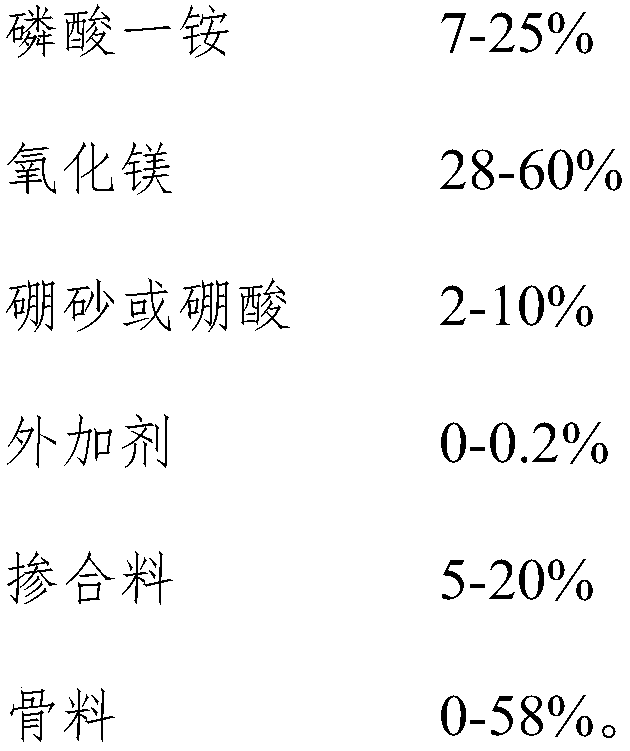

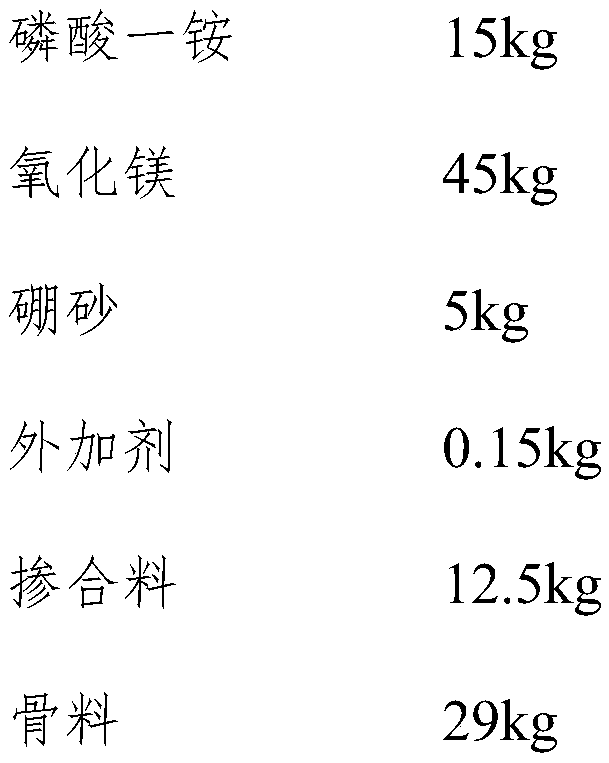

[0087] (2) Mixing material: raw materials such as monoammonium phosphate, magnesium oxide, borax, admixture, admixture, aggregate and other raw materials of the concrete crack repair material A based on phosphorus and magnesium materials are used by the metering system according to a certain amount in a specific production site. According to the proportion measurement, the phosphorus-magnesium-based dry-mixed material is prepared through the mixing and stirring system, packed and shipped to the site, and then the required amount of phosphorus-magnesium-based dry-mixed material is put into the mixing tank, and the specified amount of water is added to the tank to ensure that the fluidity is 220mm , stir evenly;

[0088] (3) ...

Embodiment 2

[0093] (1) Grooving: use a concrete wall slotting machine to chisel grooves along the cracks on the cracked concrete structure surface, the groove width is 20mm, the depth is 20mm, the shape is U-shaped, and the grooves are cleaned with high-pressure air;

[0094] (2) Mixing material: raw materials such as monoammonium phosphate, magnesium oxide, borax, admixture, admixture, aggregate and other raw materials of the concrete crack repair material A based on phosphorus and magnesium materials are used by the metering system according to a certain amount in a specific production site. According to the ratio measurement, the phosphorus-magnesium-based dry-mixed material is prepared through the mixing and stirring system, packed and shipped to the site, and then the required amount of phosphorus-magnesium-based dry-mixed material is put into the mixing tank, and the specified amount of water is added to the tank to ensure that the fluidity is 180mm , stir evenly;

[0095] (3) Grout...

Embodiment 3

[0100] (1) Grooving: use a concrete wall slotting machine to chisel grooves along the cracks on the cracked concrete structure surface, the groove width is 50mm, the depth is 60mm, the shape is V-shaped, and the grooves are cleaned with high-pressure air;

[0101] (2) Mixing material: raw materials such as monoammonium phosphate, magnesium oxide, borax, admixture, admixture, aggregate and other raw materials of the concrete crack repair material A based on phosphorus and magnesium materials are used by the metering system according to a certain amount in a specific production site. According to the ratio measurement, the phosphorus-magnesium-based dry-mixed material is prepared through the mixing system, packed and shipped to the site, and then the required amount of phosphorus-magnesium-based dry-mixed material is put into the mixing tank, and the specified amount of water is added to the tank to ensure that the fluidity is 260mm , stir evenly;

[0102] (3) Grouting: without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com