Profile structure of elevator car ceiling lamp and elevator car ceiling lamp

A technology for elevator cars and profiles, which is applied to elevators, transportation and packaging in buildings. It can solve the problems of customers feeling uncomfortable, increasing the height of the ceiling, increasing the number of lamps, etc., and achieves simple process, improved comfort, and reduced The effect of the dark zone phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

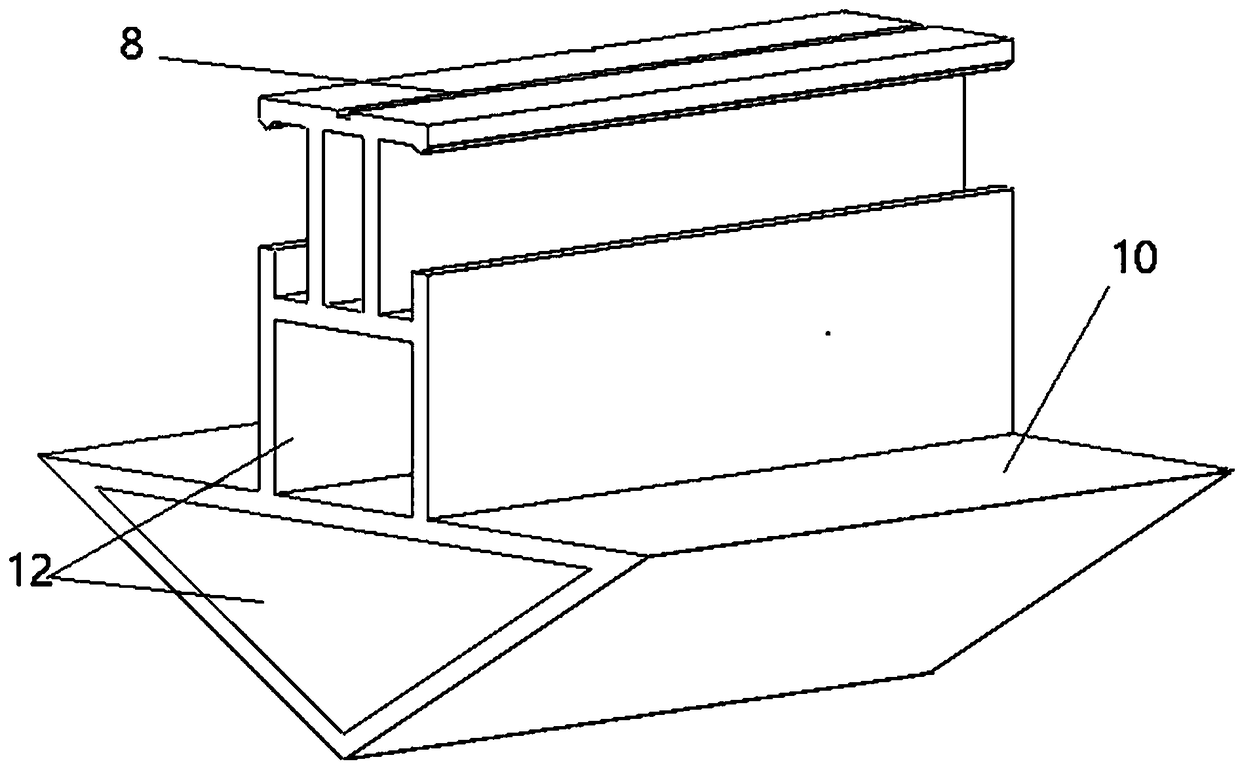

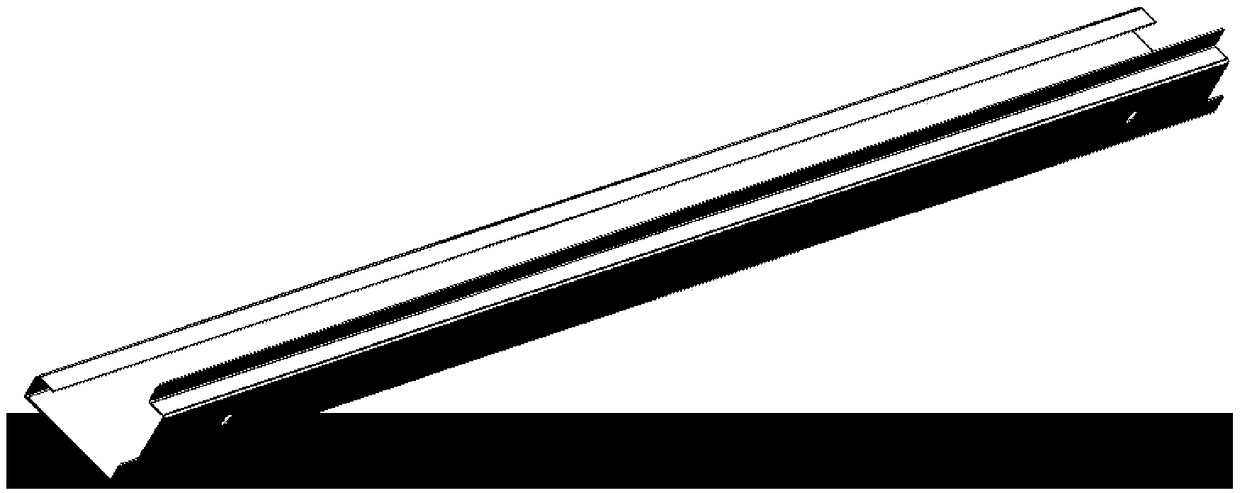

[0026] Embodiment: As shown in the accompanying drawings, this elevator car dome light profile structure mainly includes a lamp fixing card 7, a punching positioning groove 8, a reinforcement hole 9, a lamp mounting surface 10, an assembly positioning groove 11, and a mounting rod through groove 12 , profile A13, profile B14, a reinforcing hole 9 is set in the middle of the profile A13, a lamp fixing card 7 is above the reinforcing hole 9, a lamp mounting surface 10 is set outside the lower part of the reinforcing hole 9, and multiple punching holes are provided on both sides and the upper side of the profile A13 for positioning Slot 8, assembly positioning groove 11 is set on the inner side of the bottom of the profile A13, the lamp fixing card 7 is on both sides of the upper end of the profile B14, the lower part of the lamp fixing card 7 is connected to the installation rod through groove 12, and the upper surface on both sides of the installation rod through groove 12 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com