Preparation method of ultra-fine and large-height-width-ratio grid transparent electrode

A transparent electrode, high-to-width ratio technology, used in equipment for making conductive/semiconductor layers, cable/conductor manufacturing, circuits, etc., which can solve problems such as poor stability, limited large size, and limited viscosity of printing materials , to ensure the stability and improve the stability of the electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

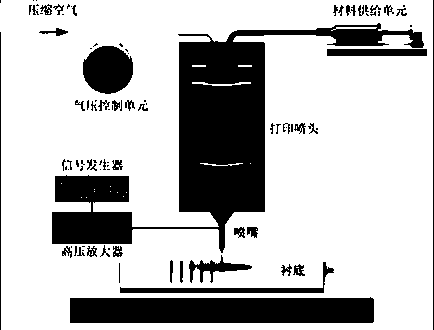

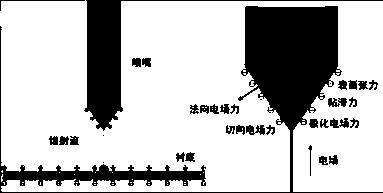

Method used

Image

Examples

Embodiment 1

[0062] In this embodiment, nano-silver particles are used as the main component of the printing material. The printing material is composed of organic solvents, thickeners, surfactants and nano-silver particles dispersedly distributed.

[0063] The concrete process of this embodiment is as follows

[0064] S1: print initialization

[0065] Put the nano-silver paste into the material supply unit, wherein the nano-silver paste is composed of four sizes of nano-silver particles of 20nm, 60nm, 80nm and 100nm according to the mass fraction of 20wt.%, 30wt.%, 30wt.%, 20wt.%. The viscosity of the silver paste is 13000 cP, the silver content is 65wt.%, the surface tension is 44dyne / cm, and the volume resistivity is 5.5×10 -6 Ω·cm. The AC pulse power supply is connected to the nozzle, and the nozzle adopts a stainless steel needle with an inner diameter of 60 μm. Move the nozzle to the initial printing position, set the distance between the nozzle and the substrate as 0.3 mm, and s...

Embodiment 2

[0074] In this embodiment, a mixture of silver nanoparticles and graphene is used as the main component of the printing material. The printing material is composed of an organic solvent, a thickener, a surfactant, and dispersedly distributed nano-silver particles, nano-silver particles and graphene.

[0075] S1: print initialization

[0076] Put the nano-silver paste and graphene into the material supply unit, wherein the nano-silver paste uses 20nm, 60nm, 80nm and 100nm four sizes of nano-silver particles according to the mass fraction of 20wt.%, 30wt.%, 30wt.%, 20wt.%. Composition, the viscosity of nano-silver paste is 18000cP, the silver content is 70wt.%, the surface tension is 50dyne / cm, and the volume resistivity is 5.0×10 -6 Ω·cm. The mass fraction of graphene is 10%. The AC pulse power supply is connected to the nozzle, and the inner wall of the nozzle is coated with conductive material with an inner diameter of 30 μm. Move the nozzle to the initial printing positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com