Preparation method of alumina supporter with large porosity and high mechanical strength

A technology of alumina carrier and mechanical strength, which is applied in the direction of catalyst carrier, chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of low mechanical strength of alumina carrier and insufficient pore size, so as to reduce the force and improve the catalytic performance. Activity, the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

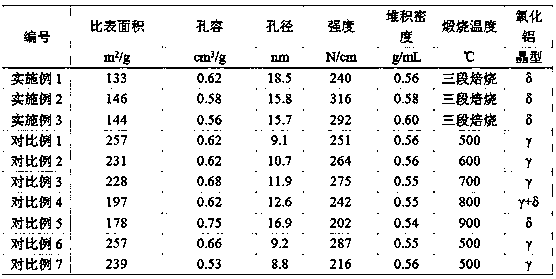

Examples

Embodiment 1

[0033] Weigh 204.0 g of pseudo-boehmite (produced by Nanhan Chemical Co., Ltd., the particle diameter is about 8 Å), add 4.5 g of scallop powder, and knead for 5 min at a speed of 50 r / min. Weigh 68 wt% of concentrated nitric acid and add it into 210 g of deionized water to prepare a dilute solution. The amount of nitric acid used is 3.0 wt%. After the powder kneading is completed, the above dilute nitric acid solution will be slowly added for 2.5 minutes, and then kneaded for 8 minutes to obtain the glued pseudo-boehmite. Then, the glued pseudo-boehmite was extruded using a four-leaf clover mold (Φ1.45 mm) at a speed of 50 r / min and a power of 130 W. Place the extruded strips at room temperature to dry for 2 hours, then put them in an oven at 120 °C, dry them for 2 hours, take them out for shaping, the speed is 400 r / min, and the length of the carrier after shaping is 0.8-1 cm. Then use a 20-mesh sieve to sieve. The roasting process adopts three-stage roasting, the first s...

Embodiment 2

[0035] Weigh 204.0 g of pseudo-boehmite (produced by South Korea Chemical Co., Ltd., the particle diameter is about 8 Å), 4.5 g of scallop powder, and knead for 5 min at a speed of 50 r / min. Nitric acid with a concentration of 68.0% was weighed and slowly added to 210 g of deionized water to prepare a dilute solution. The amount of nitric acid used was 3.0 wt%. Slowly add the dilute acid solution to the kneaded boehmite for 2.5 minutes, and keep kneading for 10 minutes to make the pseudo-boehmite fully glued into a ball, and then put it in the extruder and extrude it into strips, using a four-leaf Straw mold (Φ1.45 mm) was used to extrude the strands at a speed of 50 r / min and a power of 150 W. After extruding, let it stand at room temperature in a dark place for 336 h, take it out and dry it at 120 °C for 2 h, then carry out shaping at a speed of 450 r / min. After shaping, the length of the carrier is between 0.8-1 cm, placed in a 20-mesh standard sieve, and then put into a m...

Embodiment 3

[0037] Weigh 153.0 g of pseudoboehmite (produced by South Korea Chemical Industry Co., Ltd., the particle diameter is about 8 Å), weigh 47.0 g of PURALSB powder (produced by Sasol Germany, the grain size is 45-60 Å), and weigh the field cyanine powder 4.5 g, knead the above three for 5 min at a speed of 50 r / min. Nitric acid with a concentration of 68.0% was weighed and slowly added to 210.0 g of deionized water to prepare a dilute solution. The amount of nitric acid used was 3.0 wt%. As mentioned above, add the dilute acid solution to the kneaded pseudo-boehmite, continue kneading for 8-10 minutes to obtain a sticky pseudo-boehmite, place it in the extruder and extrude it, and the speed is 50 r / min, the power is 140 W, after the completion, it is placed at room temperature to dry for 2 h, and the strips are extruded in the form of four leaves, and the mold is Φ1.45 mm. Then put it in an oven at 120°C, dry for 2 hours, take it out, and shape it at a speed of 425 r / min. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com