Fabrication method of porous micro-scaffold and its application in tissue regeneration and repair

A technology of tissue regeneration and production method, applied in the field of regenerative medicine, can solve the problems of undeveloped stem cell survival, expansion, directed differentiation, injectable three-dimensional porous micro-scaffold, etc., to promote stem cell proliferation, improve adherence performance, small physical effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Example 1 Preparation of Sodium Alginate Three-Dimensional Porous Microscaffold

[0107] 1.1. Preparation of sodium alginate three-dimensional porous scaffold (AS)

[0108] Sodium alginate (alginate) used in this study was RGD polypeptide (GGGGRGDASSP, purchased from Shanghai Qiangyao).

[0109] Modification method of RGD-alginate (RA):

[0110] Add EDC / NHS to sodium alginate solution, stir at room temperature for 4 hours, add RGD polypeptide and stir well, and then stand at 4°C overnight; then transfer the solution to a dialysis bag (3.5kDa) for dialysis for 3 days, then freeze-dry for 24 hours to obtain RA ; Sealed and stored at -20°C.

[0111] Dissolve 2.0g RA in 100mL deionized water, transfer it to a 24-well plate after fully dissolved, 0.5ML / well, then place the plate in a 4°C refrigerator for 2h, and a -20°C refrigerator for 8h, then freeze-dry for 24h . After freeze-drying was completed, calcium chloride (2%, w / v) solution was added into the well plate, 1 ...

Embodiment 2

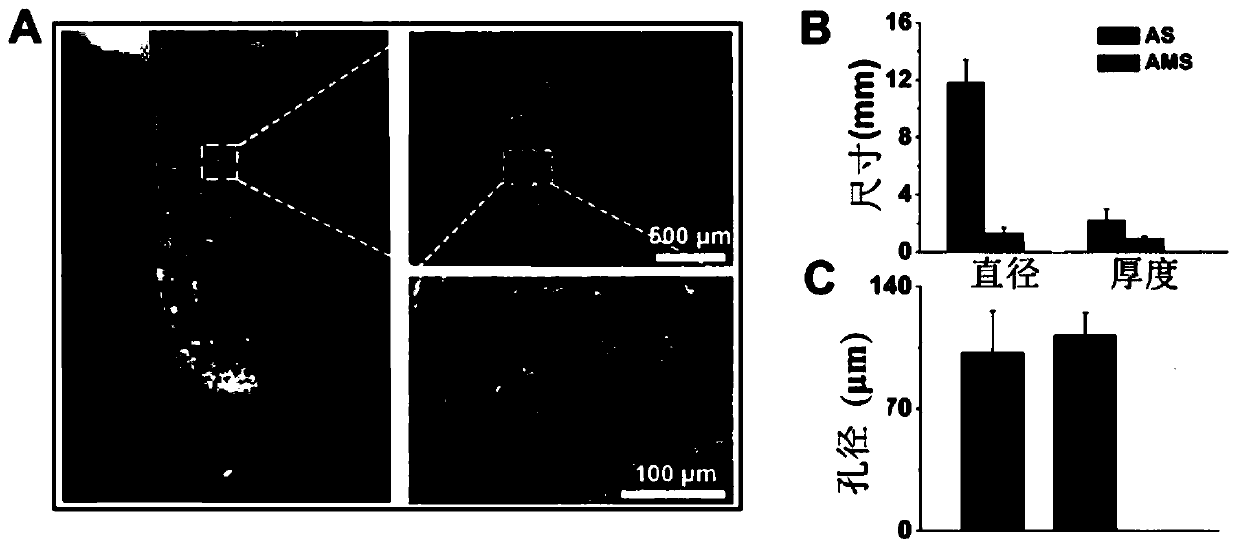

[0115] Example 2 Characterization of Sodium Alginate Three-dimensional Porous Microscaffold

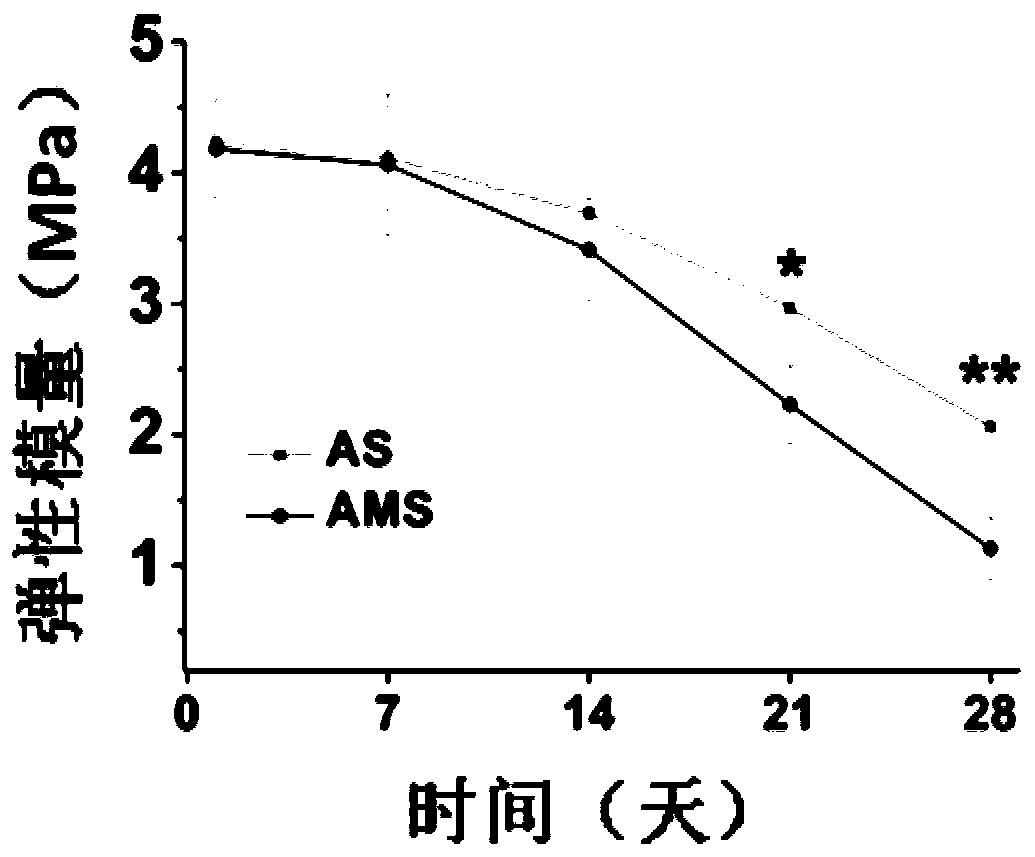

[0116] Scanning electron microscopy (SEM; S-4800; Hitachi, Japan) was used to characterize the microstructure (pore size, porous morphology, etc.) To measure the elastic modulus of each scaffold.

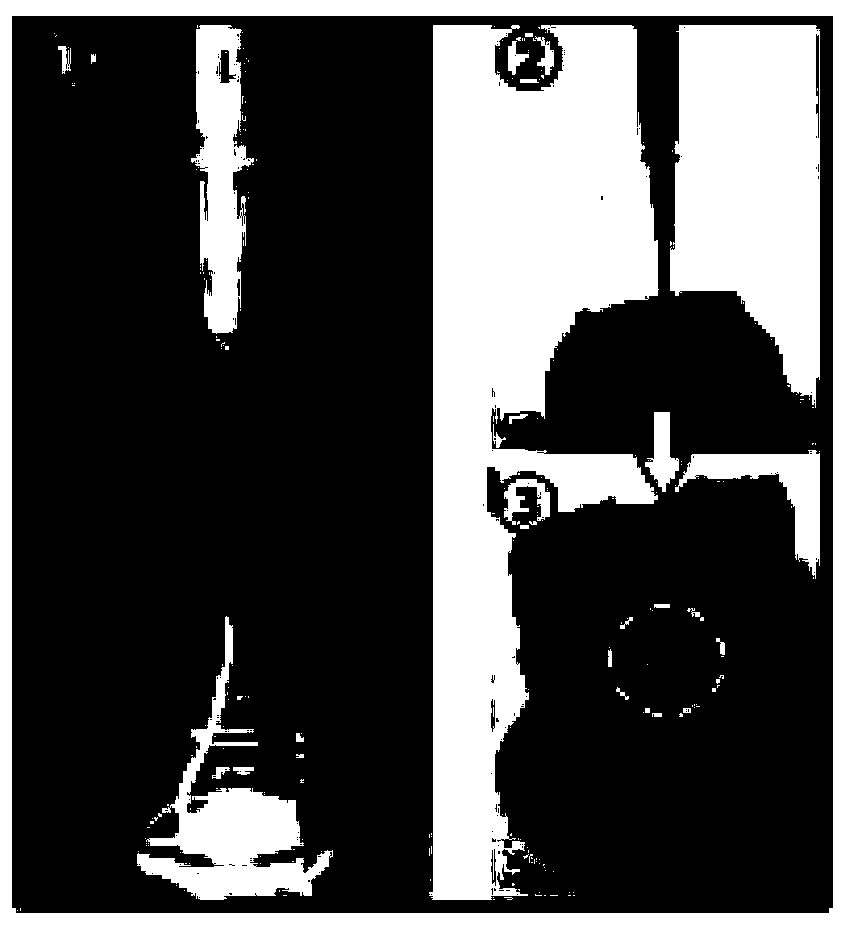

[0117] Soak the freeze-dried micro-scaffold in PBS, after it fully absorbs water and swells, filter off the PBS, add a little low-concentration sodium alginate solution to the micro-scaffold and mix well, then transfer to a syringe (1mL size) for freeze-drying . For in vivo experiments, just add the cell suspension to the micro-scaffold and mix well before injection. Injectability was verified with dense tissue.

[0118] Experimental results:

[0119] like figure 1 As shown in A, SEM results show that AMS has a three-dimensional porous structure with high connectivity, and its pore structure is not damaged; as figure 1 As shown in B-1C, the size of the scaffold is about 1 mm, and th...

Embodiment 3

[0122] Embodiment 3 injectable AMS preparation

[0123] The prepared AMS was soaked in PBS at 4°C for 48h; then the PBS was filtered off, the AMS was transferred to a 1ml syringe, the injection plunger was plugged, and sealed and stored at 4°C after freeze-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com