Surface acoustic wave microfluidic chip and method for forming acoustic focal region with micrometer size

A microfluidic chip and surface acoustic wave technology, applied in the field of microfluidics, can solve the problem that the spatial resolution of the ultrasonic acoustic focal region can only be millimeter-level, and achieve diversified adjustment methods, convenient control, and expanded application space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention also provides a method for preparing the above-mentioned surface acoustic wave microfluidic chip, which includes the following steps:

[0037] E01: Fabricate the first interdigital transducer and the second interdigital transducer on the surface of the piezoelectric substrate by photolithography, coating and lift-off processes;

[0038] E02: Fabrication of microfluidic systems using photolithography, casting and demolding processes;

[0039] E03: bonding the microfluidic system on the surface of the piezoelectric substrate.

[0040] Further, the specific steps of the preparation method of the above surface acoustic wave microfluidic chip are as follows:

[0041] 1) Preparation of surface acoustic wave chip: prepare interdigitated electrodes on the piezoelectric substrate material, the preparation process includes one or more of electron beam evaporation, magnetron sputtering, lift-off, soft lithography, through the above process ...

Embodiment 1

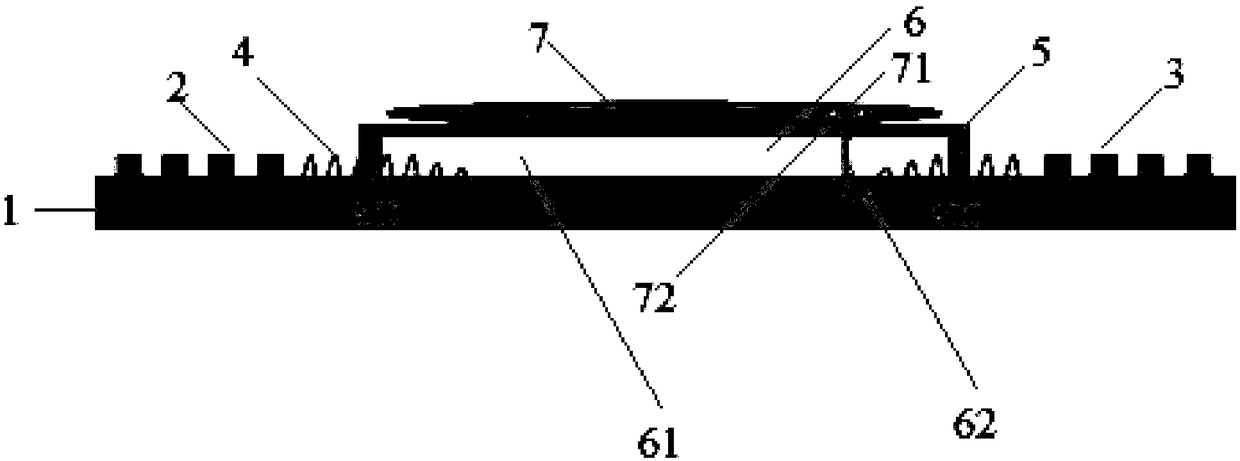

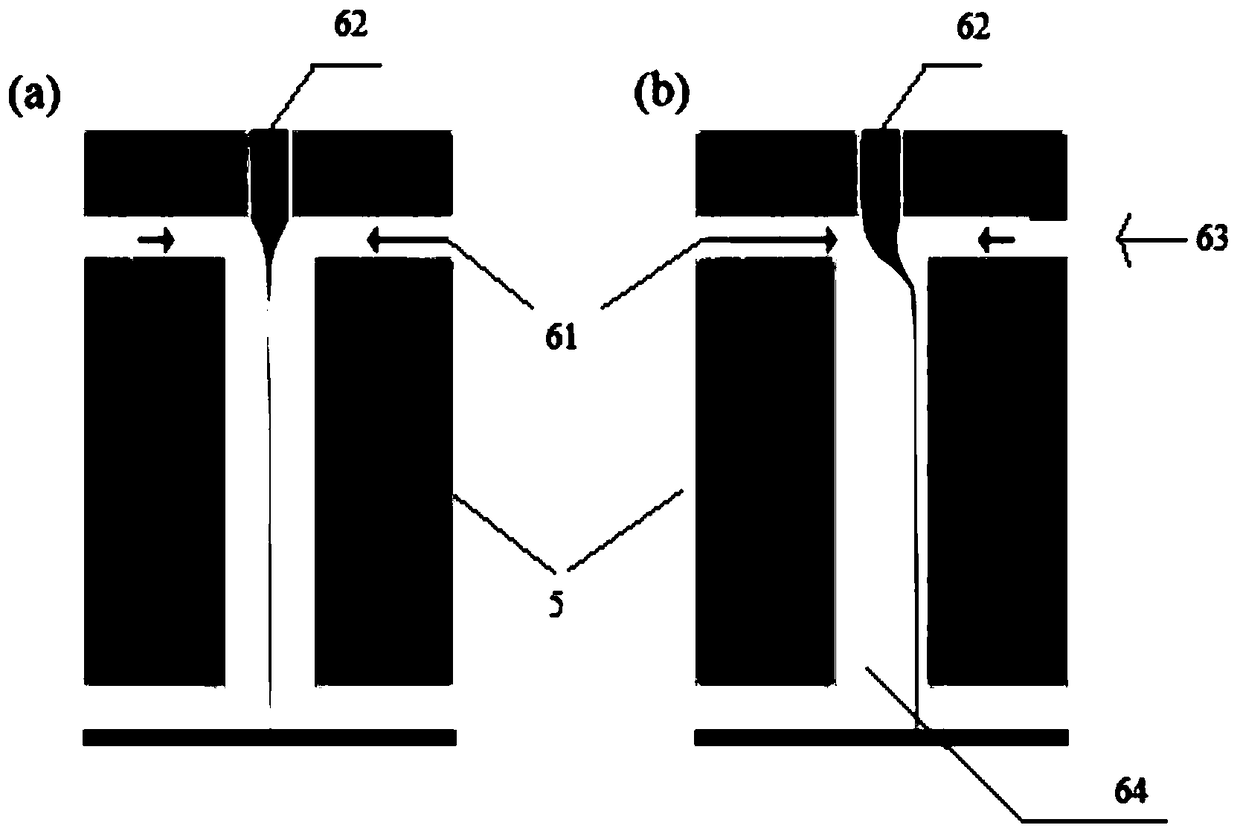

[0052] A surface acoustic wave microfluidic chip, such as figure 1 with figure 2 As shown, it includes a piezoelectric substrate 1 and a first interdigital transducer 2 and a second interdigital transducer 3 arranged on the piezoelectric substrate 1, and the piezoelectric substrate 1 is also provided with a micrometer for forming an acoustic focal region. A fluidic control system 5, the microfluidic system 5 is between the first IDT 2 and the second IDT 3; the microfluidic system 5 is provided with a closed internal flow channel 6, the internal flow channel 6 The bottom of the piezoelectric substrate 1, and the inner channel 6 includes a first channel 63 and a second channel 64 (see figure 2 ), the first flow channel 63 and the second flow channel 64 are on the same horizontal plane and contain parts perpendicular to each other, the first flow channel 63 is provided with the first fluid 61 of low acoustic impedance, and the second flow channel 64 is provided with a high-aco...

Embodiment 2

[0054] A method for forming an acoustic focal region, such as figure 1 with figure 2 shown, including the following steps:

[0055] S11: Provide the above-mentioned surface acoustic wave microfluidic chip according to Embodiment 1 of the present invention;

[0056] S12: Prepare the biological sample 7 to be tested, place the biological sample 7 on the top of the microfluidic system 5 on the surface acoustic wave microfluidic chip, and overlap with the second fluid 62;

[0057] S13: The surface acoustic wave 4 is transmitted through the first interdigital transducer 2 and the second interdigital transducer 3, and the surface acoustic wave 4 is not conducted through the first fluid 61 and the second fluid 62, in the microfluidic system 5 An independent acoustic wave region is formed and transmitted to the biological sample 7 at the top of the microfluidic system 5 to form an acoustic focal region, which can be obtained in the biological sample 7-stimulated neurons 71 and unst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com