A kind of foamed carbon film and preparation method thereof

A carbon film and bubble technology, applied in the field of foamed carbon film and its preparation, can solve the problems of poor sound regulation, poor temperature resistance of the film, slow cooling speed, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

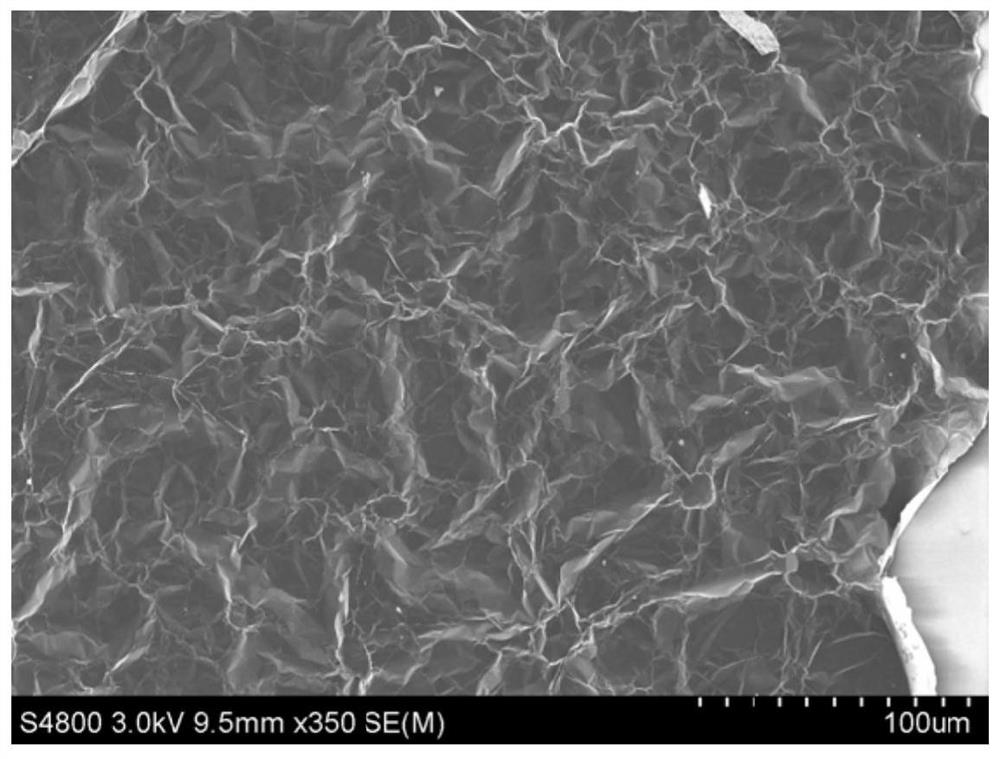

[0027] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 0.5ug / mL, and anodized aluminum oxide (AAO) was used as a substrate to form a film with a thickness of 600nm.

[0028] (2) Place the graphene oxide film attached to the AAO film in a closed container, and fumigate with HI steam at 60°C for 10 h.

[0029] (3) The above-mentioned reduced graphene oxide film is sublimated and evaporated at 100° C., and the solid transfer agent camphor is evenly coated on the surface of the graphene film, and heated for a period of time at a temperature below the melting point of the solid transfer agent by 5 degrees. Put the graphene film coated with the solid transfer agent at room temperature, and the graphene film will be automatically separated from the AAO film.

[0030] (4) Slowly volatilize the solid transfer agent from the graphene film supported by the solid transfer agent obtained above at a temperature at which the solid transfer agent...

Embodiment 2

[0040] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 10ug / mL, and anodized aluminum oxide (AAO) was used as a substrate to form a film with a thickness of 200nm.

[0041] (2) Place the graphene oxide film attached to the AAO film in a closed container, and fumigate with HI steam at 100°C for 1 h.

[0042] (3) The above-mentioned reduced graphene oxide film is melted and coated at a low temperature (52° C.), and the solid transfer agent paraffin is evenly coated on the surface of the graphene film, and heated for a period of time at a temperature lower than the melting point of the solid transfer agent by 5 degrees. time. Put the graphene film coated with the solid transfer agent at room temperature, and the graphene film will be automatically separated from the AAO film.

[0043] (4) Slowly volatilize the solid transfer agent supported graphene film obtained above at 120° C. to obtain an independent self-supporting reduced grap...

Embodiment 3

[0053] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 2ug / mL, and anodized aluminum oxide (AAO) was used as a substrate to form a film with a thickness of 280nm by suction filtration.

[0054] (2) Put the graphene oxide film attached to the AAO film in an airtight container, and use HI steam at 80°C for 9h.

[0055] (3) The method of coating the above-mentioned reduced graphene oxide film solution uniformly coats the solid transfer agent aluminum chloride on the surface of the graphene film, and heats for a period of time at a temperature below the melting point of the solid transfer agent by 5 degrees. Put the graphene film coated with the solid transfer agent at room temperature, and the graphene film will be automatically separated from the AAO film.

[0056] (4) Slowly volatilize the solid transfer agent by the graphene film supported by the solid transfer agent obtained above at 180° C. to obtain an independent self-supporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com