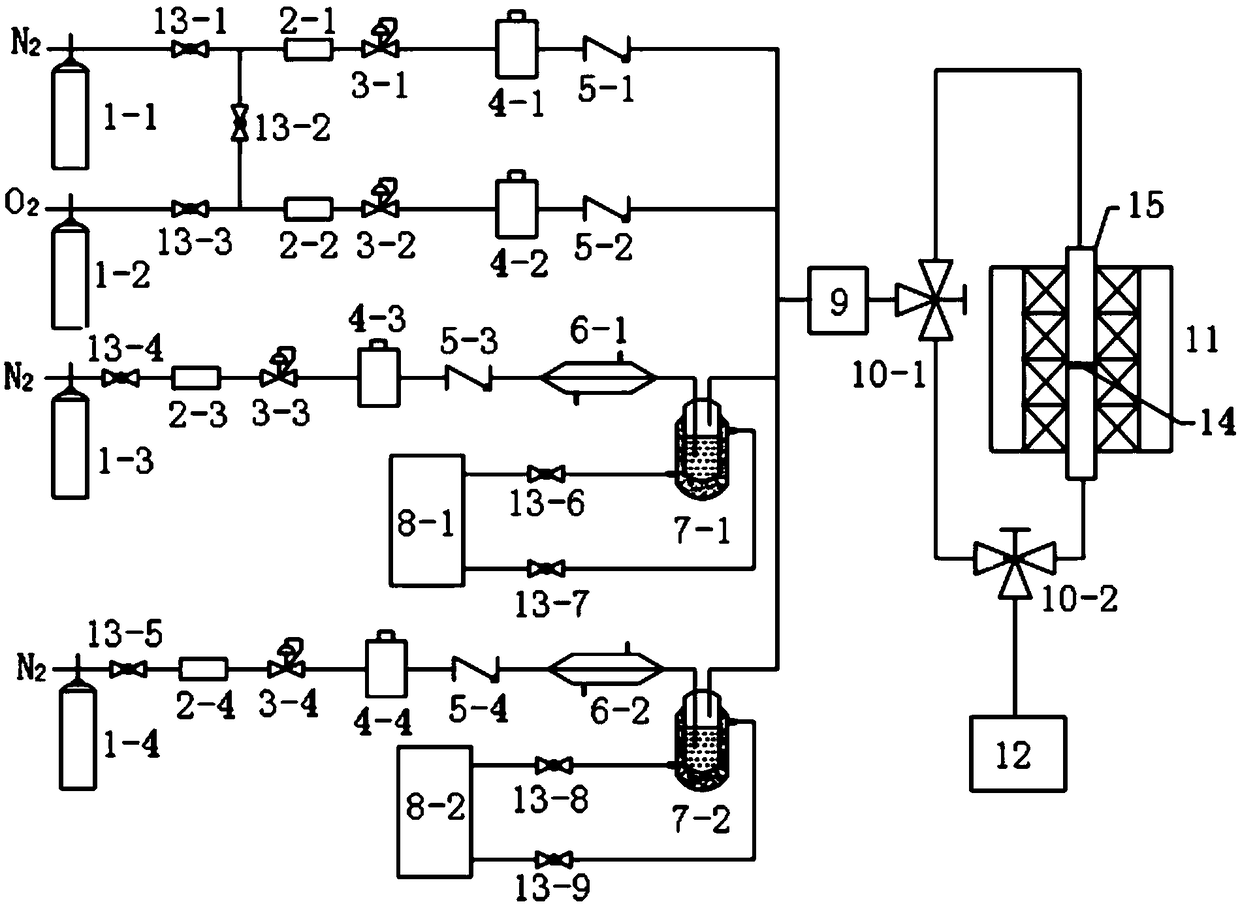

Experimental device for measuring catalytic oxidation efficiency of volatile organic compounds

A volatile organic compound, catalytic oxidation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of meeting the high temperature in the furnace and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

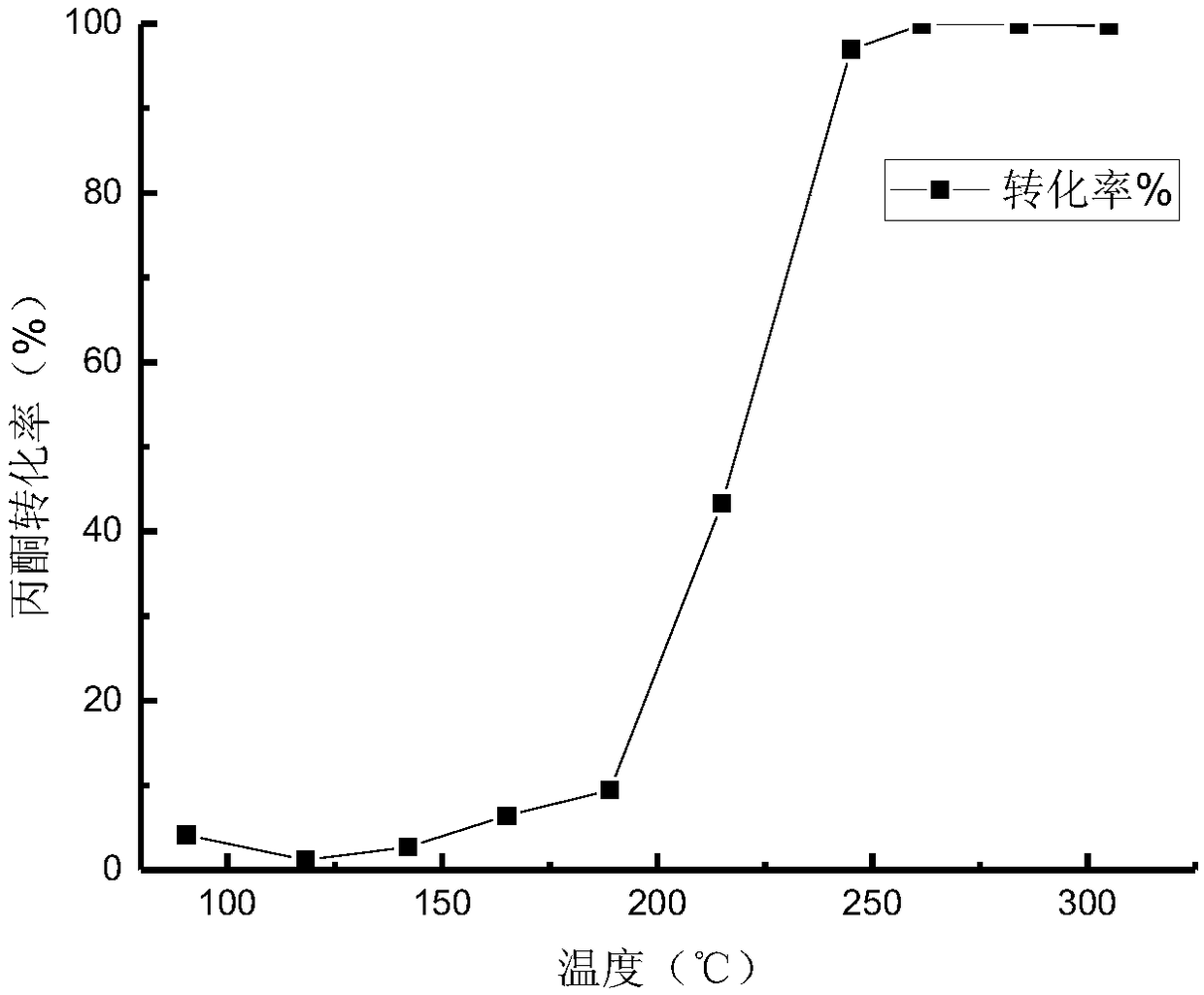

Embodiment 1

[0047] The selection of equipment and materials in Example 1 is as follows: the target VOCs used is acetone, and the catalyst is a noble metal catalyst prepared by an equal volume impregnation method. The active component of the noble metal catalyst is Pt, and the carrier is TiO 2 , the added cocatalyst component is Ce(NO 3 ) 3 . Acetone was analytically pure acetone produced by Tianjin Yuanli Chemical Co., Ltd.

[0048] The gas chromatograph in the gas chromatograph system 12 is a GC9790 II gas chromatograph, and the detector configured by the gas chromatograph is a hydrogen flame ionization detector.

[0049] Set the temperature of constant temperature circulator A 6-1 to 0°C to maintain a stable acetone inlet concentration. Adjust the three-way ball valve A10-1 and the three-way ball valve B10-2, so that the gas path directly connected between the two three-way ball valves A and B is opened, and the gas path entering the reaction tube 15 is closed. Acetone, O 2 The mi...

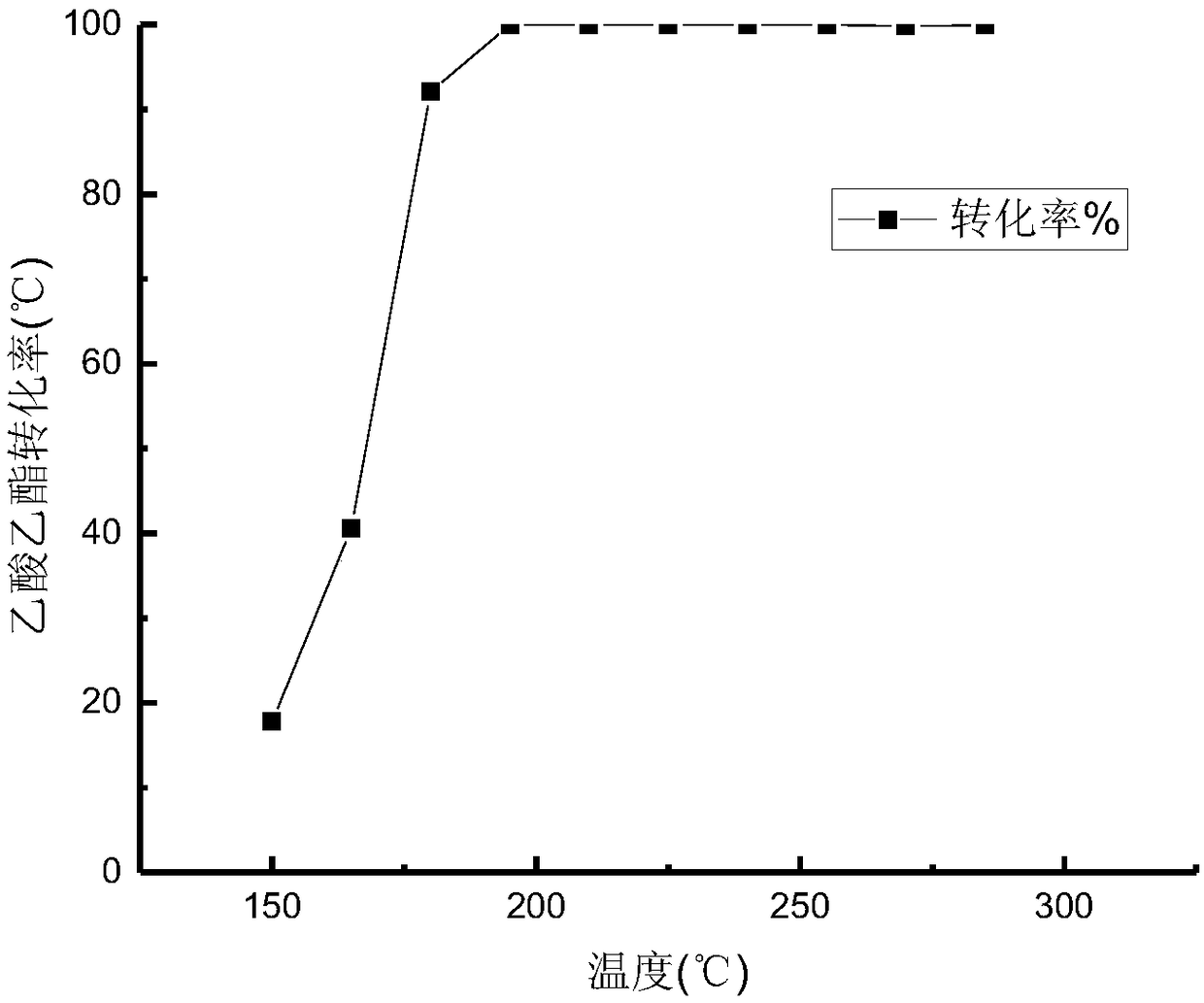

Embodiment 2

[0054] The selection of each equipment and material in this embodiment 2 is as follows: the target VOCs used is ethyl acetate, and the catalyst is a hydrotalcite catalyst. The hydrotalcite catalyst is Co(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 Co / Al LDHs prepared by titration of O and alkali solution, the preparation process is: preparation solution I: Co(NO 3 ) 2 ·6H 2 O(29.103g) and Al(NO 3 ) 3 9H 2 O (7.5026g), the molar concentration ratio is 5:1, configured into a 250ml solution, the total concentration is 0.48mol / L. Preparation of Solution II: NaOH (0.24mol, 9.6g) and NaOH 2 CO 3 (0.04mol, 4.2396g), made into 250ml solution. Add solution I and solution II dropwise to a beaker with an appropriate amount of deionized water at the same time, and stir vigorously at the same time, adjust the drop rate of solutions I and II to control the pH of the mixed solution to 10-11, and suspend the obtained solution after the addition is completed The solution was placed in a d...

Embodiment 3

[0062] This implementation case 3 mainly explores the influence of water vapor on the catalyst activity. The selection of equipment and materials in the experiment is as follows: the target VOCs used is acetone, and the Pt catalyst and acetone are the same as those in Example 1. The gas chromatograph adopts GC9790Ⅱ type gas chromatograph, and the detector configured by the gas chromatograph is a hydrogen flame ionization detector.

[0063] The external circulation temperature of the saturated generator A 7-1 (acetone bubbling bottle) was set to 0°C, and the external circulation temperature of the saturated generator B7-2 (water vapor bubbling bottle) was set to 70°C. Adjust the three-way ball valve A 10-1 and the three-way ball valve B 10-2 so that the gas path directly connected between the two three-way ball valves A and B is opened, and the gas path entering the reaction tube 15 is closed. h 2 O, acetone, and O 2 The mixed gas directly enters the gas chromatography system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com