Material for microwave deiced road surface and preparation method thereof

A microwave and wave absorbing agent technology is applied in the field of new microwave deicing pavement materials and their preparation, as well as in the field of road pavement. The effect of high surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

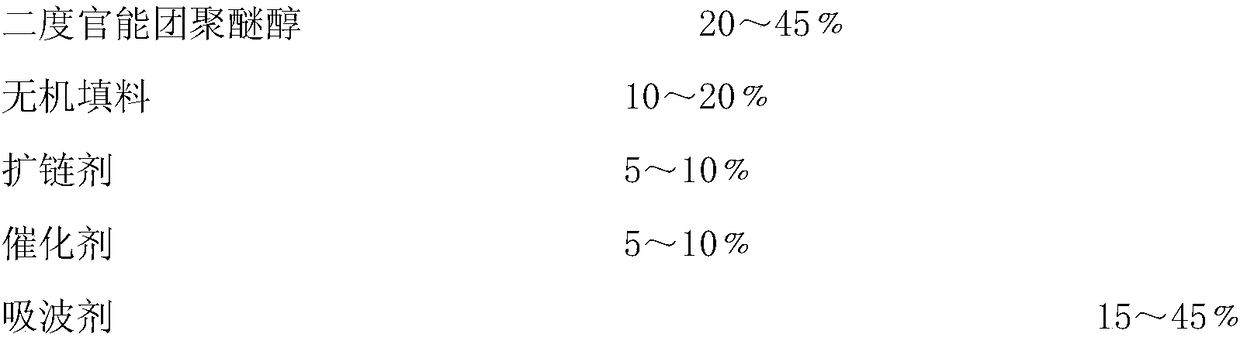

Method used

Image

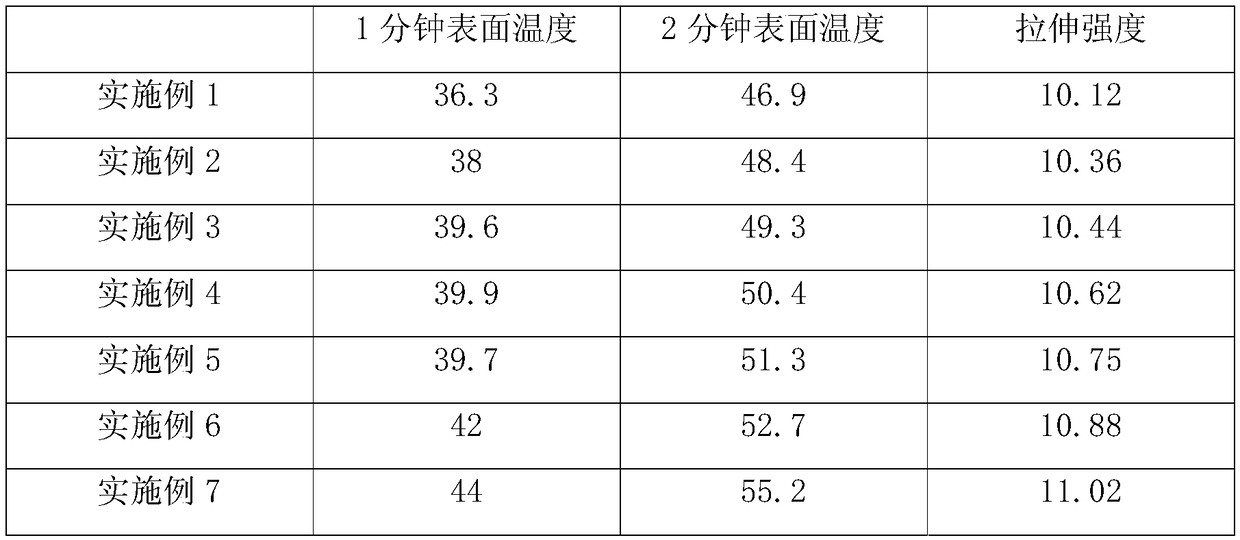

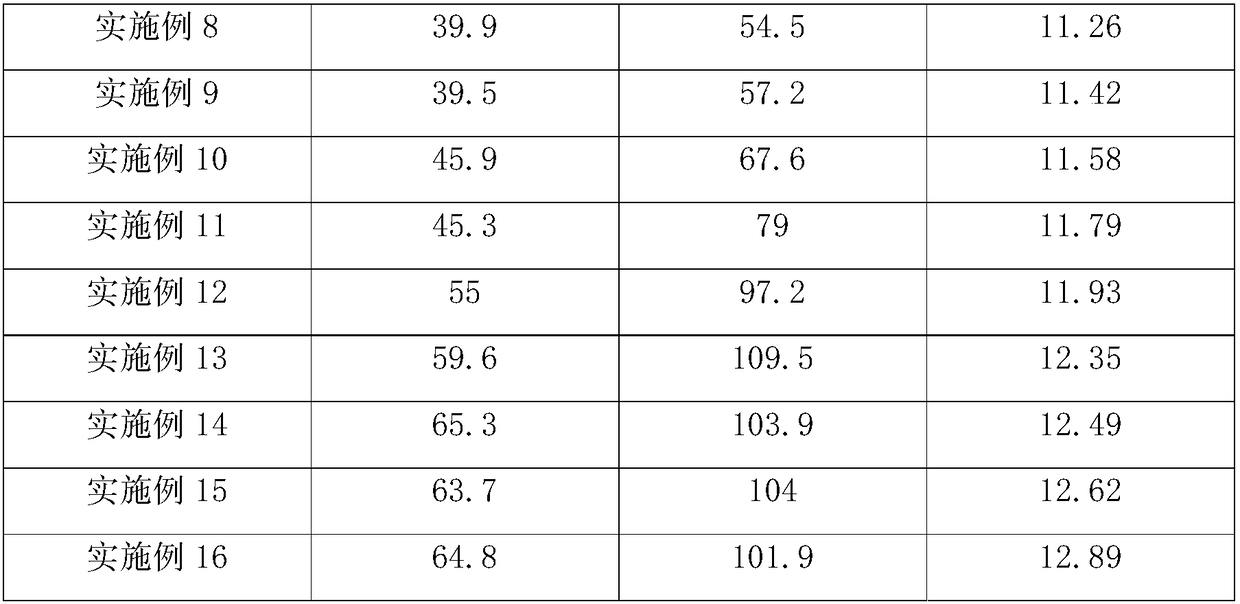

Examples

Embodiment 1

[0021] Component A: Weigh 20 g of xylene methane diisocyanate (functionality 2.7) and 10 g of xylene methane diisocyanate (functionality 2.1), blend at 500 r / min for 15 min, and discharge.

[0022] Component B: Take 32.6g of two-degree functional group alcohol PPG400 polypropylene glycol, 5.3g of dibutyltin dilaurate, 3.6g of isophorone diamine, 2.5g of silicon dioxide, 4.5g of halloysite, 3.5g of carbonyl iron powder, Stir and disperse for 30 minutes under the condition of 800r / min, and discharge.

[0023] Weigh and mix components A and B at a mass ratio of 2:3. The performance test results are shown in Table 1.

Embodiment 2

[0025] Component A: Weigh 20 g of xylene methane diisocyanate (functionality 2.7) and 10 g of xylene methane diisocyanate (functionality 2.1), blend at 500 r / min for 15 min, and discharge.

[0026] Component B: Take 31.8g of two-degree functional group alcohol PPG400 polypropylene glycol, 5.4g of dibutyltin dilaurate, 3.2g of isophorone diamine, 2.3g of silicon dioxide, 4.8g of halloysite, 4.3g of carbonyl iron powder, Stir and disperse for 30 minutes under the condition of 800r / min, and discharge.

[0027] Weigh and mix components A and B at a mass ratio of 2:3. The performance test results are shown in Table 1.

Embodiment 3

[0029] Component A: Weigh 20 g of xylene methane diisocyanate (functionality 2.7) and 10 g of xylene methane diisocyanate (functionality 2.1), blend at 500 r / min for 15 min, and discharge.

[0030] Component B: take 32.7g of two-degree functional group alcohol PPG400 polypropylene glycol, 5.3g of dibutyltin dilaurate, 3.3g of isophorone diamine, 2.1g of silicon dioxide, 4.4g of halloysite, 4.9g of carbonyl iron powder, Stir and disperse for 30 minutes under the condition of 800r / min, and discharge.

[0031] Weigh and mix components A and B at a mass ratio of 2:3. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com