Environment-friendly type water purifying agent for industrial sewage and preparation method thereof

A technology of industrial sewage and water purifier, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of insignificant treatment effect, high treatment cost, and long treatment cycle, and achieve Excellent water purification effect, the effect of improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

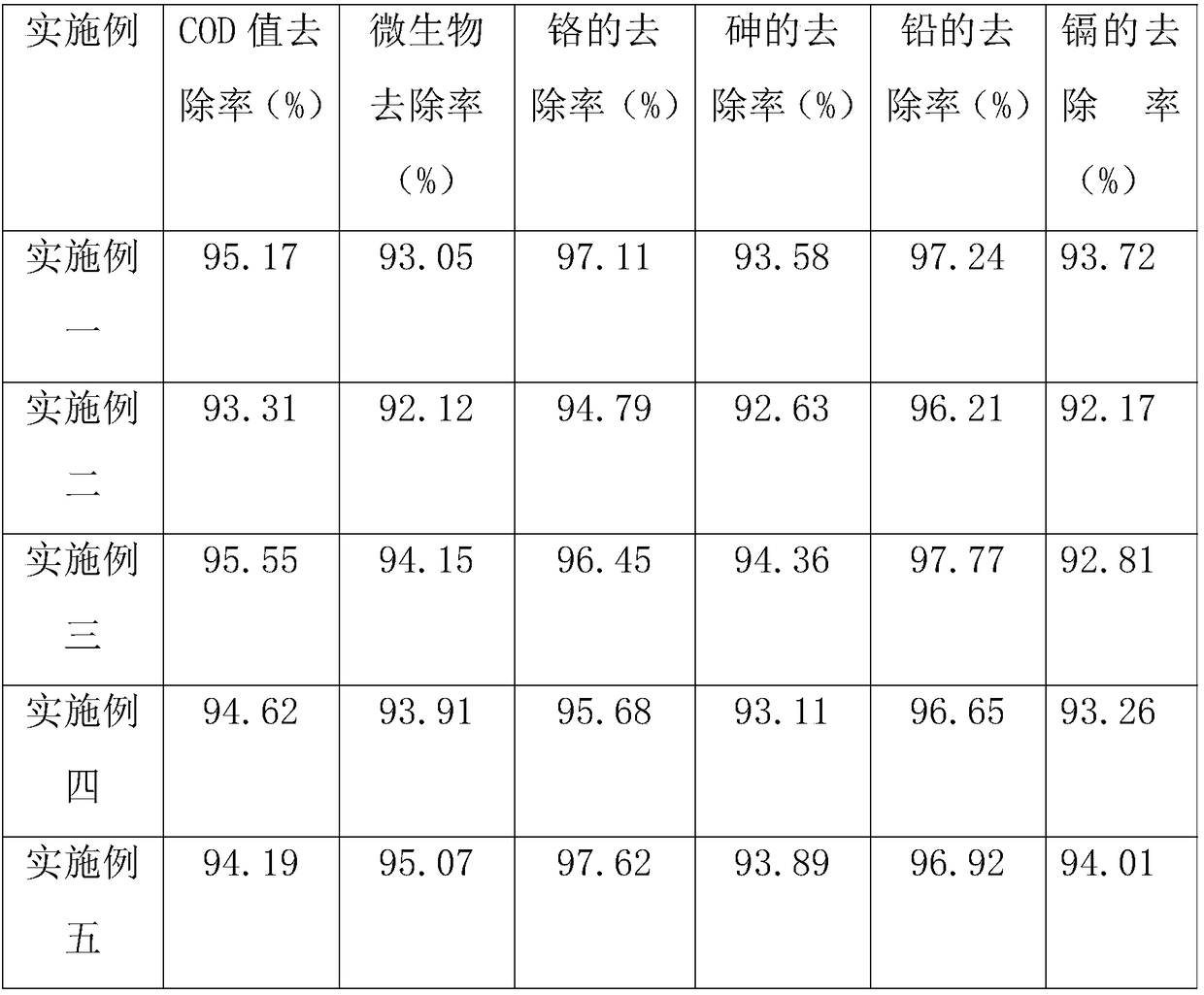

Examples

Embodiment 1

[0040] This embodiment provides an environment-friendly water purifier for industrial sewage. The raw materials of the water purifier include the following components in parts by weight: 38 parts of porous magnetic polyacrylamide microspheres, 20 parts of modified coconut shell charcoal, sulfonic acid 17 parts of coal, 10 parts of sepiolite, 11 parts of zeolite, 8 parts of bamboo, 8 parts of bran, 6 parts of sodium lignosulfonate, 5 parts of chitosan, 1.5 parts of polyepoxysuccinic acid, mulberry white bark 3 servings, 1.5 servings of Magnolia.

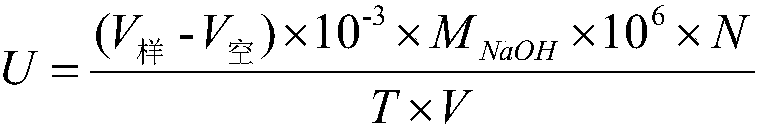

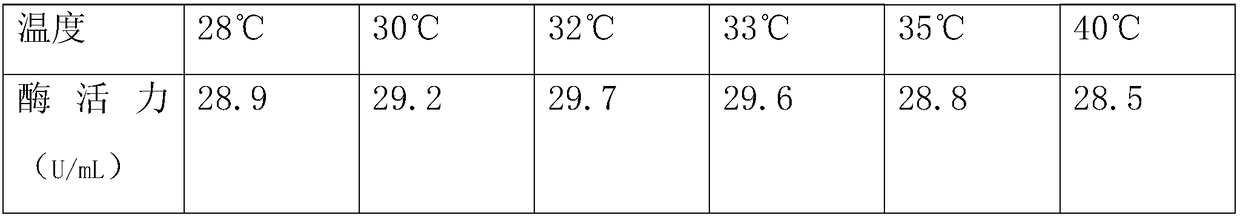

[0041] In the present embodiment, the preparation method of the modified coconut shell charcoal is: according to the mass ratio of 1:2.5, mixing coconut shell charcoal and the lipase liquid produced by the mixed fermentation of Pseudomonas aeruginosa and yeast, and then placing it at a rotating speed of In a shaking table of 155r / min, treated at 32°C for 5h, filtered and dried to obtain modified coconut shell charcoal;

[0042] Where...

Embodiment 2

[0057] This embodiment provides an environmentally friendly water purifying agent for industrial sewage. The raw materials of the water purifying agent include the following components in parts by weight: 35 parts of porous magnetic polyacrylamide microspheres, 20 parts of modified coconut shell charcoal, sulfonic acid 15 parts of coal, 10 parts of sepiolite, 10 parts of zeolite, 8 parts of bamboo, 6 parts of bran, 6 parts of sodium lignosulfonate, 4.5 parts of chitosan, 1.5 parts of polyepoxysuccinic acid, mulberry white bark 2 servings, Magnolia 1.5 servings.

[0058] In the present embodiment, the preparation method of the modified coconut shell charcoal is: according to the mass ratio of 1:2.5, mixing coconut shell charcoal and the lipase liquid produced by the mixed fermentation of Pseudomonas aeruginosa and yeast, and then placing it at a rotating speed of In a shaking table of 155r / min, treated at 32°C for 5h, filtered and dried to obtain modified coconut shell charcoal...

Embodiment 3

[0064] This embodiment provides an environment-friendly water purifier for industrial sewage. The raw materials of the water purifier include the following components in parts by weight: 38 parts of porous magnetic polyacrylamide microspheres, 22 parts of modified coconut shell charcoal, sulfonic acid 17 parts of coal, 11 parts of sepiolite, 11 parts of zeolite, 10 parts of bamboo, 8 parts of bran, 8 parts of sodium lignosulfonate, 5 parts of chitosan, 2 parts of polyepoxysuccinic acid, mulberry white bark 3 servings, 2 servings of Magnolia.

[0065] In the present embodiment, the preparation method of the modified coconut shell charcoal is: according to the mass ratio of 1:2.5, mixing coconut shell charcoal and the lipase liquid produced by the mixed fermentation of Pseudomonas aeruginosa and yeast, and then placing it at a rotating speed of In a shaking table of 155r / min, treated at 32°C for 5h, filtered and dried to obtain modified coconut shell charcoal;

[0066] Wherein,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com