Efficient machining cooling device

A technology of mechanical processing and cooling device, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc. It can solve the problems of cumbersome operation, affecting the heating effect, high processing temperature, etc., and achieves convenient operation, convenient processing, and avoids shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

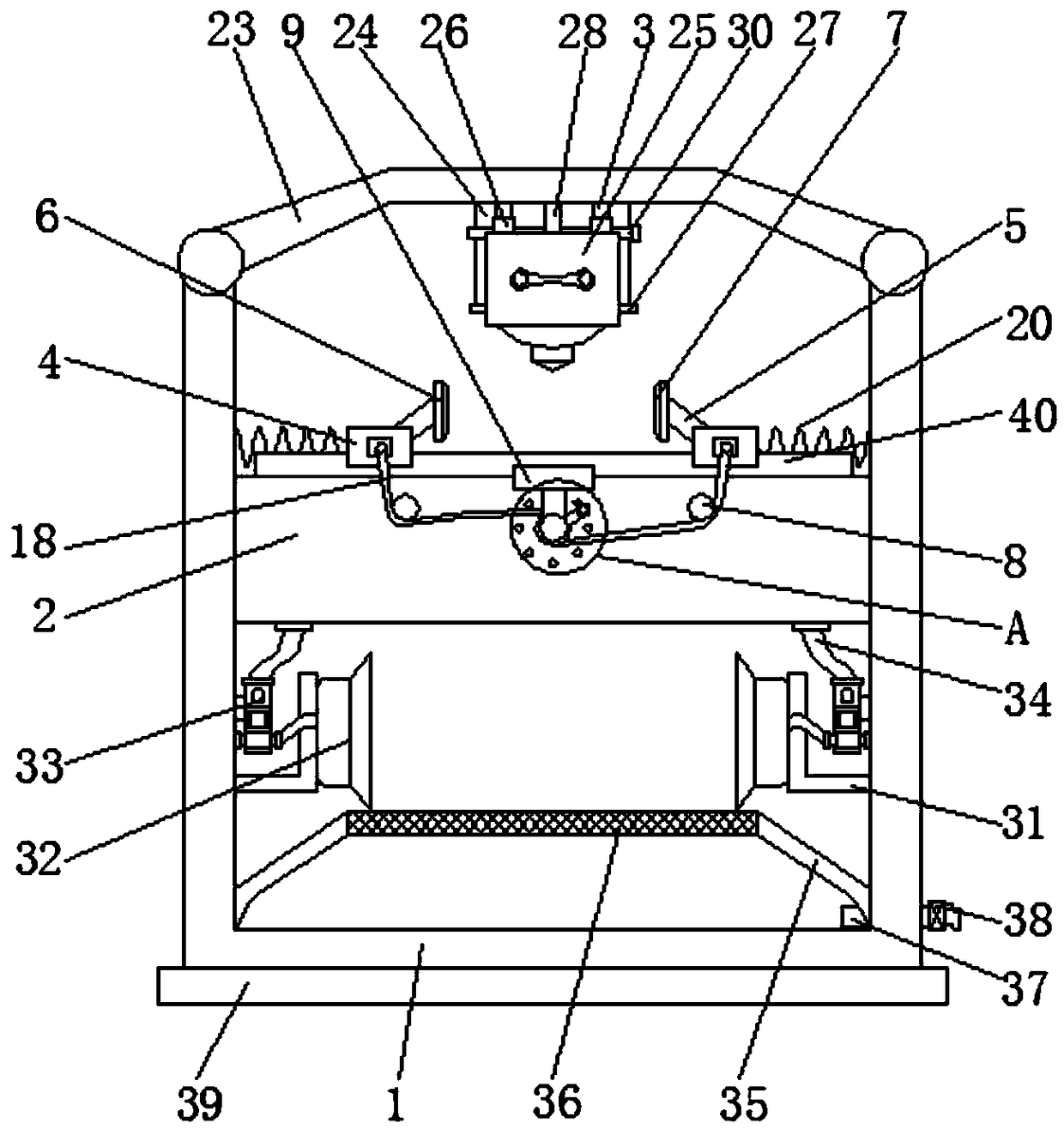

[0032] Implementation method 1, please refer to Figure 1-8, a highly efficient machining cooling device, comprising a housing 1, the top of the housing 1 is fixedly connected with a box cover 23, the bottom of the box cover 23 is fixedly connected with a connecting plate 24, and the front of the connecting plate 24 is fixedly connected with a limiting plate 28, The inner surfaces of the sliding block 26 and the limiting plate 28 are all provided with limiting holes 29, the inner surfaces of the limiting holes 29 are movably connected with the limiting rods 30, and the left and right sides of the front of the connecting plate 24 are fixedly connected with the second slide rail 3 , using the cooperation between the second slide rail 3 and the sliding block 26 can make the processing device 25 slide up and down on the second slide rail 3, and then the position of the processing device 25 can be adjusted, and then the limit rod 30 and the limit hole 29 can be used to The cooperat...

Embodiment approach 2

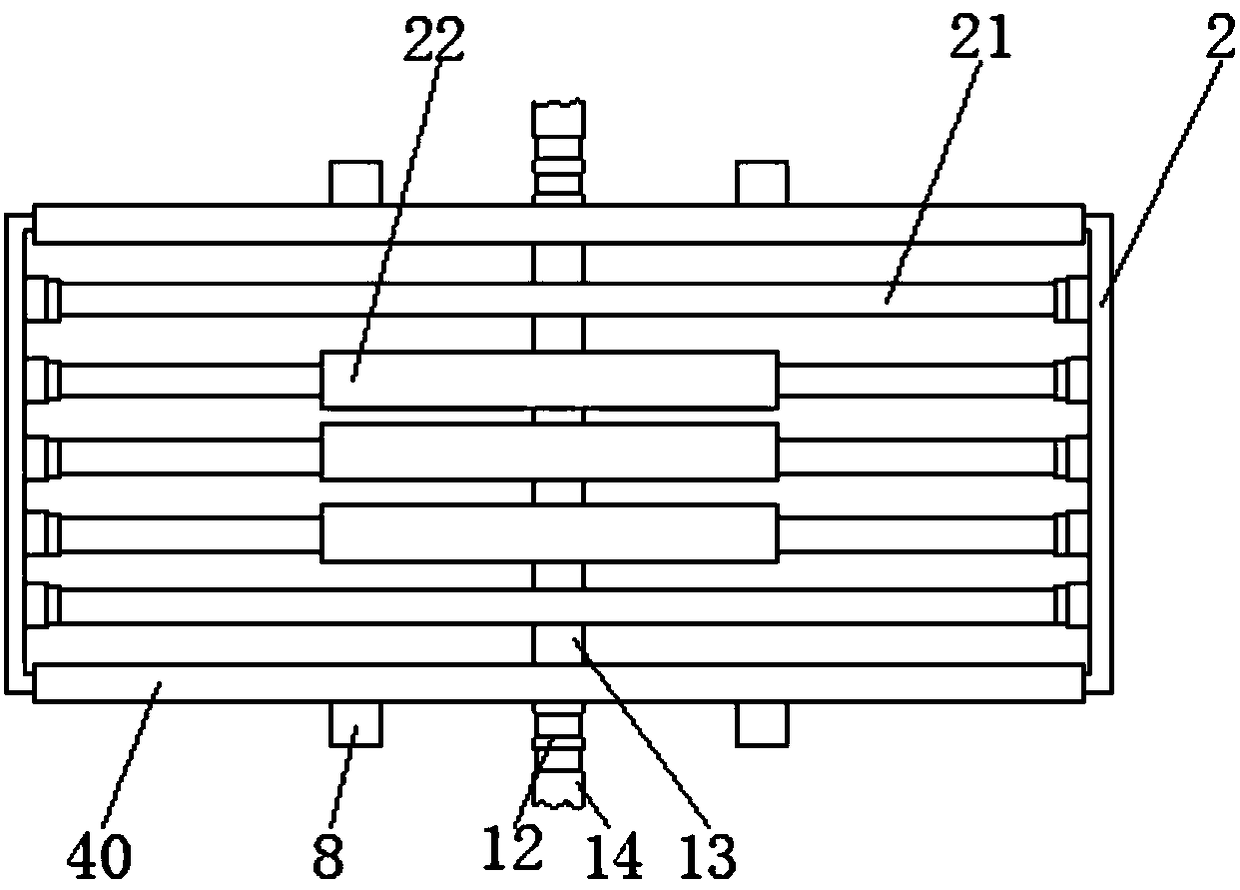

[0033] Implementation mode two, please refer to Figure 1-8 , a high-efficiency mechanically processed cooling device, comprising a casing (1), characterized in that: a cooling box (2) is fixedly connected to the inside of the casing (1), and the front and rear sides of the cooling box (2) are both The first sliding rail (40) is fixedly connected, the two first sliding rails (40) are slidingly connected with a sliding plate (4), and the opposite sides of the two sliding plates (4) are fixedly connected with a support plate (5), and the side of the support plate (5) away from the sliding plate (4) is fixedly connected with a splint (6), and one side of the splint (6) is fixedly connected with a buffer plate (7), and the cooling box The front and rear sides of (2) are all rotatably connected with guide posts (8), the front and rear sides of the cooling box (2) are all fixedly connected with fixed blocks (9), and the bottom of the fixed block (9) is fixedly connected with A conn...

Embodiment approach 3

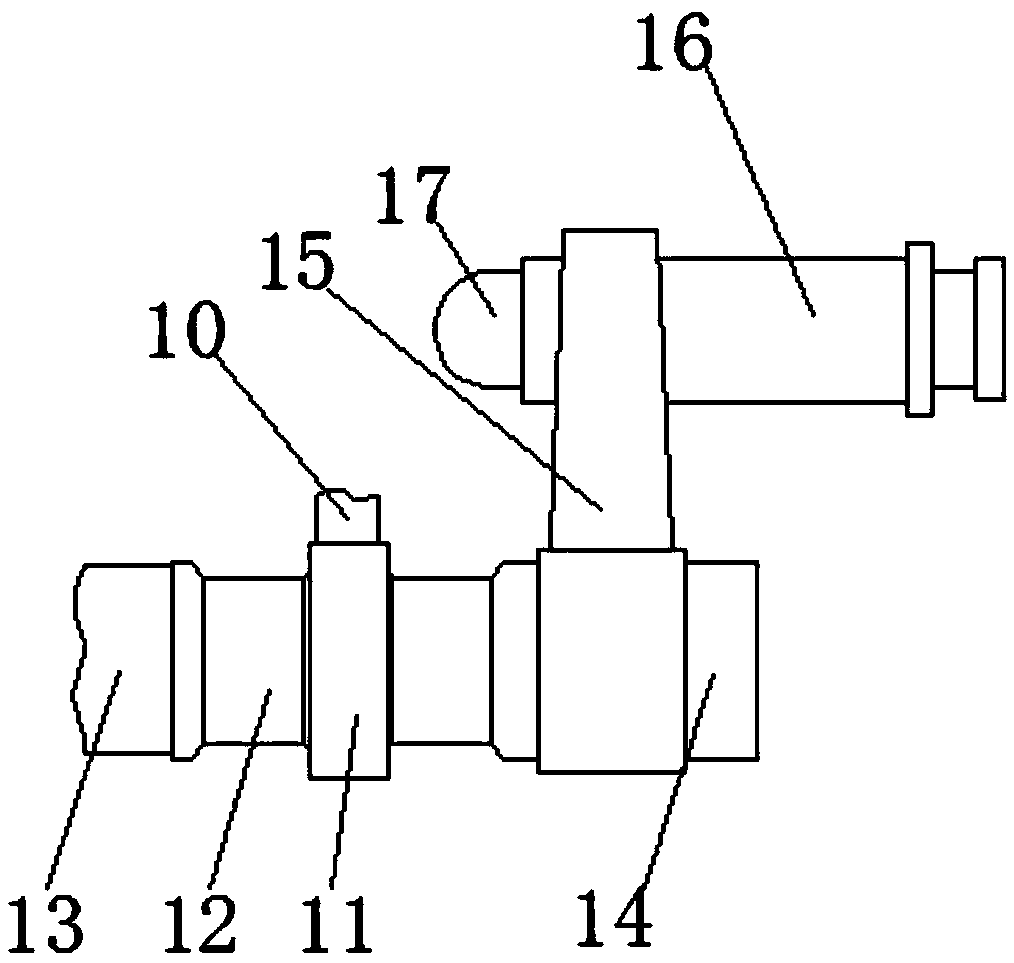

[0034] Implementation Mode 3, please refer to Figure 1-8 , a highly efficient machining cooling device, one end of the outer surface of the winding post (12) is fixedly connected with a rotating rod (14), and the outer surface of the rotating rod (14) is fixedly connected with a rocker (15) , the inner surface of the rocker (15) is fixedly connected with a handle (16), and the inner surface of the handle (16) is slidably connected with a limiting post (17).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com