Hydraulic saw for convenient electric bed cutting

A convenient electric bed and hydraulic technology, applied in the direction of sawing machine accessories, sawing machine devices, metal sawing equipment, etc., can solve the problem that the equipment cannot be kept at a certain temperature, the service time and sensitivity of the equipment are weakened, and the equipment cannot be discharged in time Heat and other problems, to reduce the frequency of maintenance, speed up the handling speed, improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

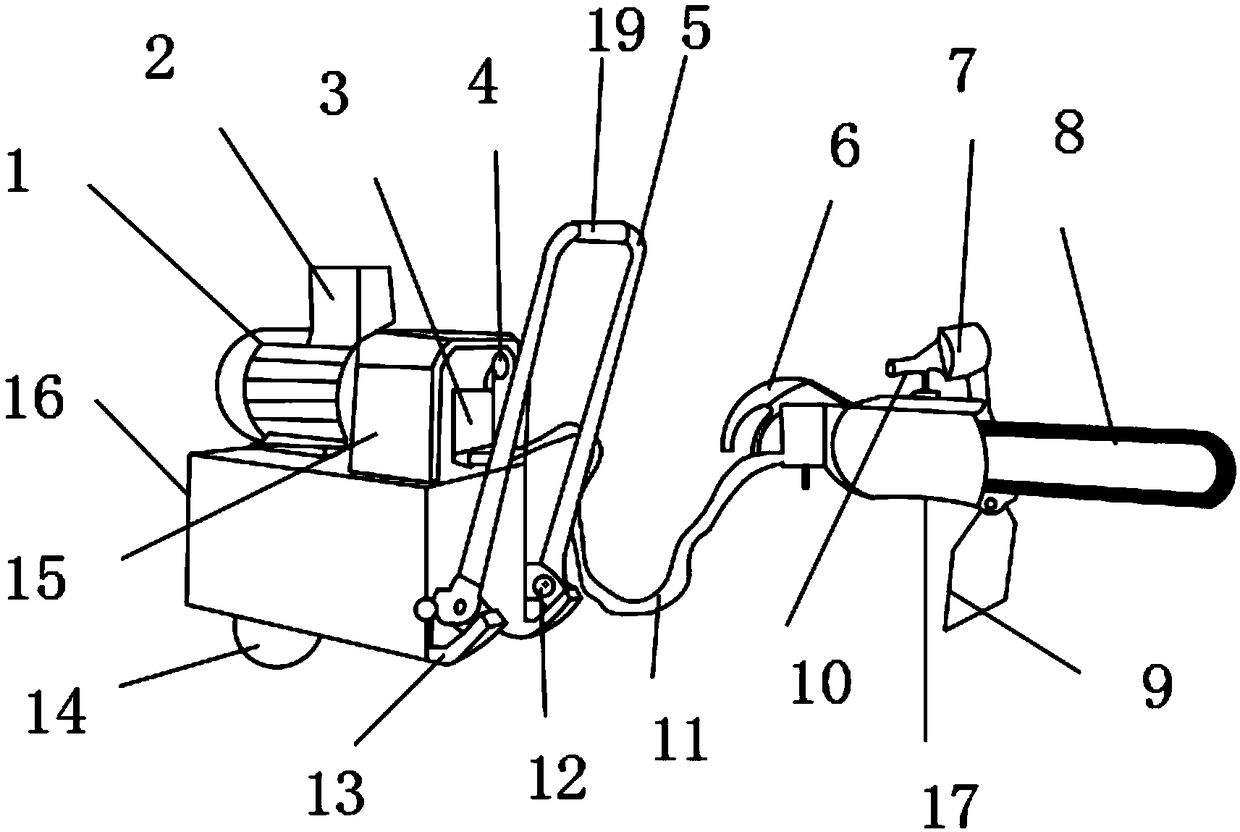

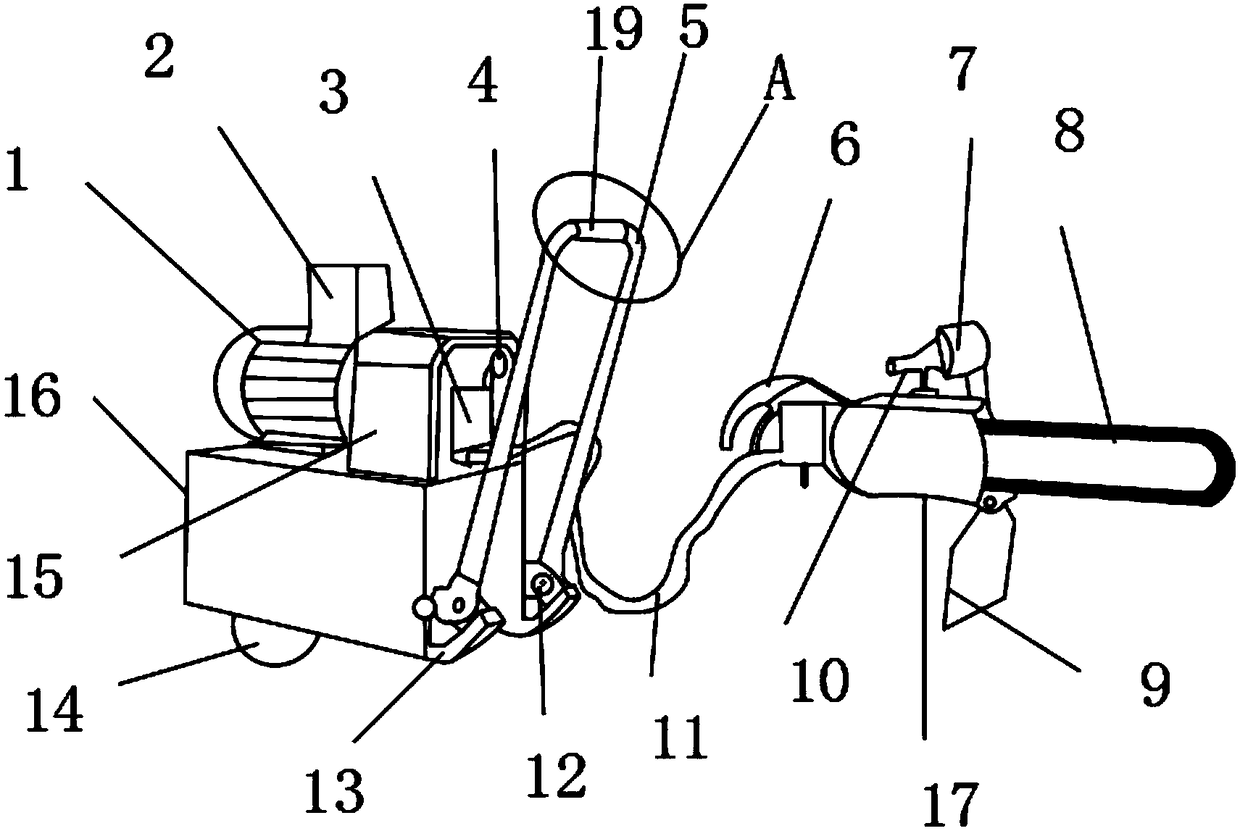

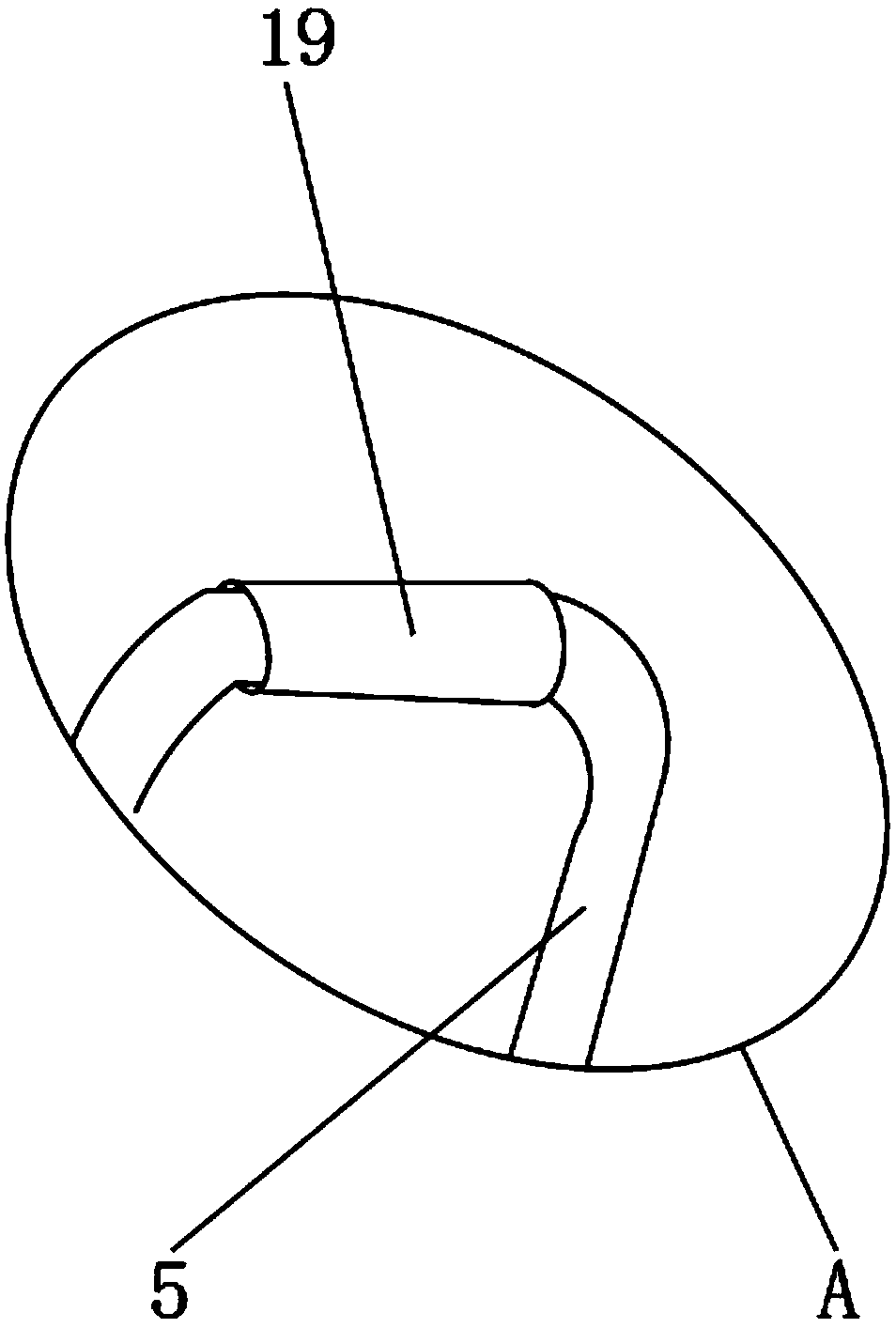

[0018] Such as Figure 1-4 As shown, a hydraulic saw that facilitates electric bed cutting includes a motor 1, an oil pipe 11, a bolt 12, and a hydraulic saw 17. A control box 2 is provided above the motor 1, and a protective plate 15 is provided on one side of the motor 1. , the bottom end of the motor 1 is provided with a fuel tank 16, and the bottom end of the fuel tank 16 is provided with a roller 14 and an anti-collision frame 13, and the upper end of the anti-collision frame 13 is provided with a rectangular pull rod 5, and the rectangular pull rod 5 passes through the bolt 12 It is movably connected with the anti-collision frame 13, and the inside of the protective plate 15 is provided with a hydraulic pump 3 and a cooling fan 18, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com