Steel structure anticorrosive coating and preparation method thereof

An anti-corrosion coating, steel structure technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of harsh conditions and complex processes, achieve low equipment requirements, simple painting process, long-term effect The effect of electrochemical protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

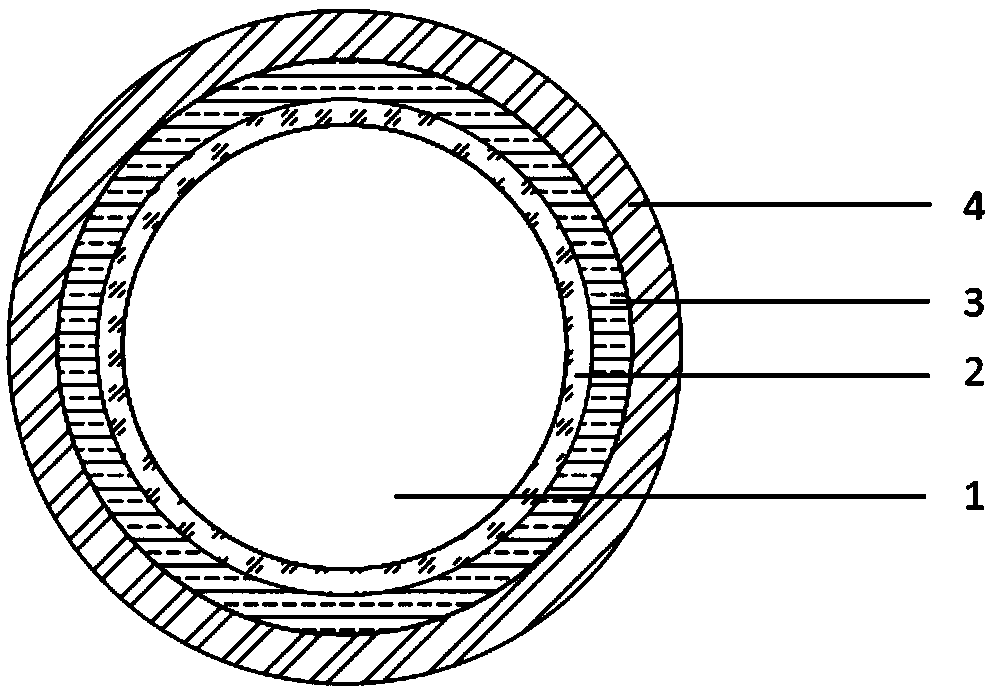

[0025] An anticorrosive coating for steel structures. Firstly, the surface of the steel structure substrate is cleaned and sandblasted to remove rust, followed by alcohol-soluble inorganic zinc-rich primer coating, polyurethane intermediate coating and fluorocarbon top coating; The alcohol-soluble inorganic zinc-rich primer is coated on the surface of the steel structure substrate, the polyurethane intermediate paint is coated on the primer, and the fluorocarbon topcoat is coated on the intermediate paint;

[0026] The mass percentages of the components of the alcohol-soluble inorganic zinc-rich primer are as follows: ethyl orthosilicate 20%, scaly zinc powder 42%, ethylene glycol 10%, butanol 12%, dilute hydrochloric acid 5%, glacial acetic acid 7%, water glass 1%, hydroxycellulose 3%;

[0027] The mass percentages of the components of the polyurethane intermediate paint are as follows: water-based polyurethane resin 43%, polycarboxylate metal salt 2.5%, sodium nitrite 1%, ethyl a...

Embodiment 2

[0036] An anticorrosive coating for steel structures. Firstly, the surface of the steel structure substrate is cleaned and sandblasted to remove rust, followed by alcohol-soluble inorganic zinc-rich primer coating, polyurethane intermediate coating and fluorocarbon top coating; The alcohol-soluble inorganic zinc-rich primer is coated on the surface of the steel structure substrate, the polyurethane intermediate paint is coated on the primer, and the fluorocarbon topcoat is coated on the intermediate paint;

[0037] The mass percentages of the components of the alcohol-soluble inorganic zinc-rich primer are as follows: 19% ethyl orthosilicate, 43% scaly zinc powder, 9% ethylene glycol, 13% butanol, 4.5% dilute hydrochloric acid, glacial acetic acid 8%, sodium pyrophosphate 1.5%, hydroxypropyl cellulose 2%,

[0038] The mass percentages of the components of the polyurethane intermediate paint are as follows: water-based polyurethane resin 44%, polycarboxylate metal salt 3.5%, sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com