Perovskite composite film, light emitting diode and preparation method of perovskite composite film

A technology of light-emitting diodes and composite thin films, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low quantum efficiency and achieve the effect of improving film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

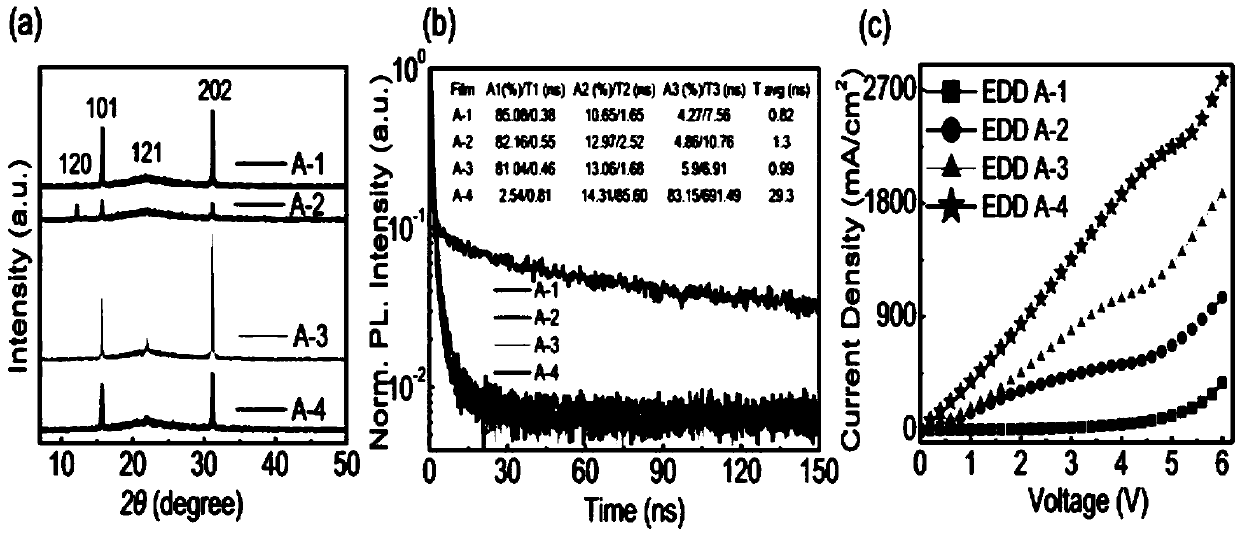

[0014] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0015] The preparation method of perovskite light-emitting layer composite film and PeLEDs is as follows:

[0016] Preparation of perovskite solution: PbBr 2 (purchased from Alfa Aesar company, the purity is 99.999%) and CsBr (purchased from Alfa Aesar company, the purity is 99.999%) are dissolved in dimethyl sulfoxide solvent (purchased from Aladdin company, purity ≥ 99.8%) in order to prepare perovskite (CsPbBr 3 ) solution. 1,3,5-tri(m-pyrid-3-yl-phenyl)benzene (TmPyPB, purchased from Suzhou Fangsheng Optoelectronics Co., Ltd., purity>99.5%) and bis[(4,6-difluorophenyl)-pyridi- nato-N,C2'](picolinate)iridium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com