A kind of preparation method of field emission array cathode

A field emission cathode and emission array technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as poor repeatability, complicated process, and high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

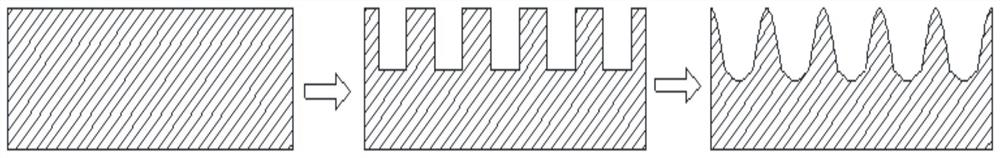

[0030] A method for preparing a field emission array cathode. In this embodiment, polycrystalline lanthanum hexaboride is selected as the cathode material, and the field emission array cathode is prepared by combining wire electric discharge cutting and electrochemical corrosion method. The process flow is as follows figure 2 Shown:

[0031] (1). Polishing and cleaning

[0032] After polishing the polycrystalline lanthanum hexaboride substrate, ultrasonically clean it with deionized water for 15 minutes;

[0033] (2). Wire cutting

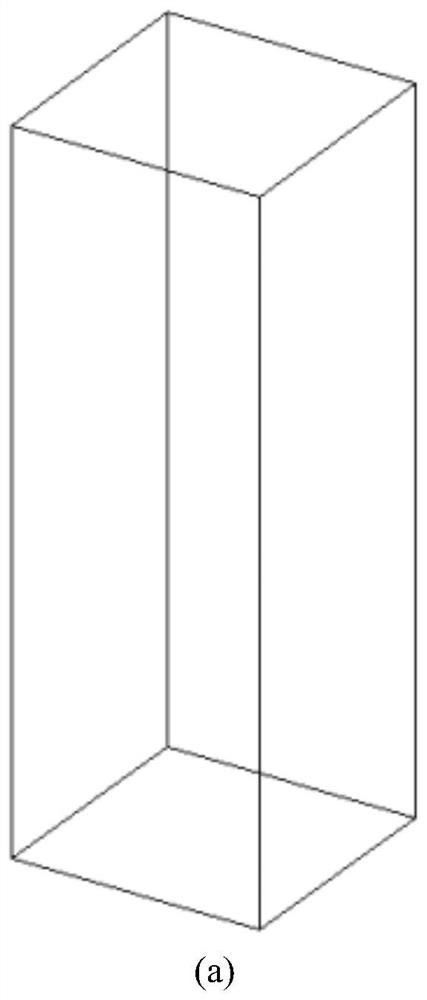

[0034] cutting a prismatic primary emitter array on a polycrystalline lanthanum hexaboride substrate by using an electric discharge cutting method;

[0035] The structural parameters of the initial emitter array are mainly as follows: the diameter of the polycrystalline lanthanum hexaboride substrate is 8mm, the thickness of the polycrystalline lanthanum hexaboride substrate is 2.5mm, the length of the emitter edge is 0.25mm, and the emitter slo...

Embodiment 2

[0043] A method for preparing a field emission array cathode. In this embodiment, polycrystalline lanthanum hexaboride is selected as the cathode material, and the field emission array cathode is prepared by combining diamond wire cutting and wet etching:

[0044] (1). Polishing and cleaning

[0045] After polishing the polycrystalline lanthanum hexaboride substrate, ultrasonically clean it with deionized water for 15 minutes;

[0046] (2). Wire cutting

[0047] Use a diamond wire cutting machine to cut out a columnar array on a polycrystalline lanthanum hexaboride substrate. When cutting, use paraffin to fix the lanthanum hexaboride substrate on the cutting board, and then adjust the parameters for cutting;

[0048] The structural parameters of the initial emitter array are mainly as follows: the diameter of the polycrystalline lanthanum hexaboride substrate is 8mm, the thickness of the polycrystalline lanthanum hexaboride substrate is 2.5mm, the length of the emitter edge i...

Embodiment 3

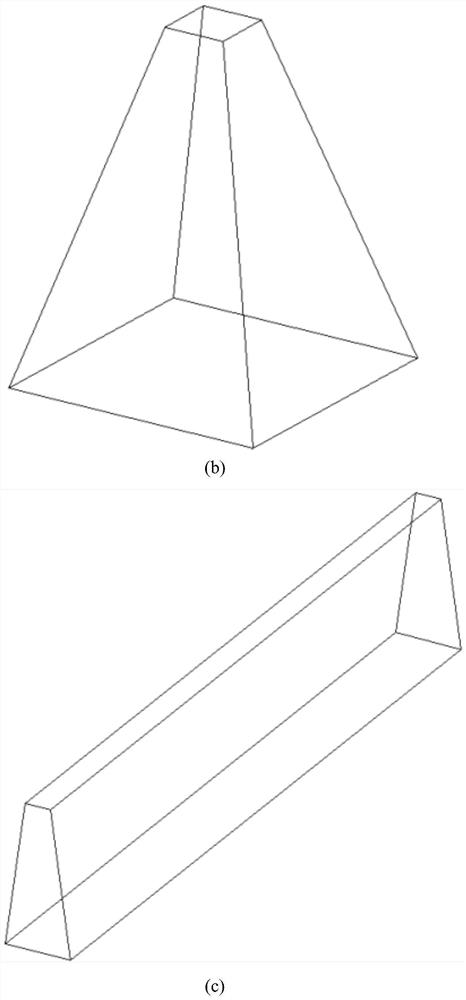

[0054] In this embodiment, a diamond wire cutting machine is used to cut a blade-shaped array on the surface of a polycrystalline lanthanum hexaboride substrate, and the shape of each field emitter in the cut blade-shaped array is like a blade, gradually narrowing from bottom to top (i.e. wide at the bottom and narrow at the top), the blade array obtained by mechanical cutting is as follows Figure 5 As shown in (a), after RIE etching, the top of the field emitter will be sharper, such as Figure 5 (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com