Fireproof wear-resistant copper core armored power cable

A technology of power cables and wear-resistant copper, which is applied to power cables with shielding layers/conductive layers, insulated cables, cables, etc., which can solve the problems of reducing the service life of power cables, poor wear resistance and tensile energy, and power cable protection. Layer damage and other problems, to achieve the effect of strengthening tensile strength and impact resistance, improving fire resistance, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

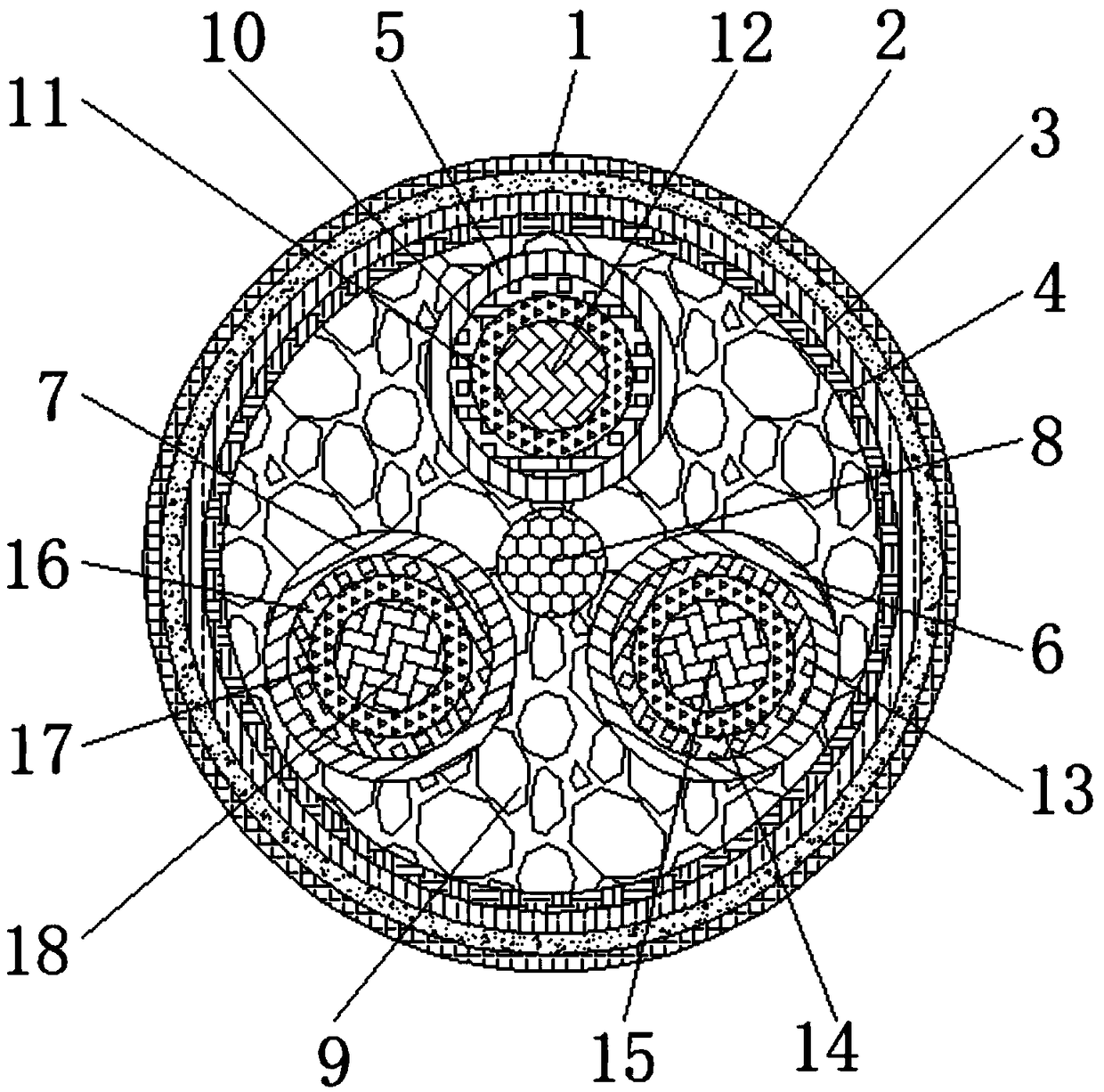

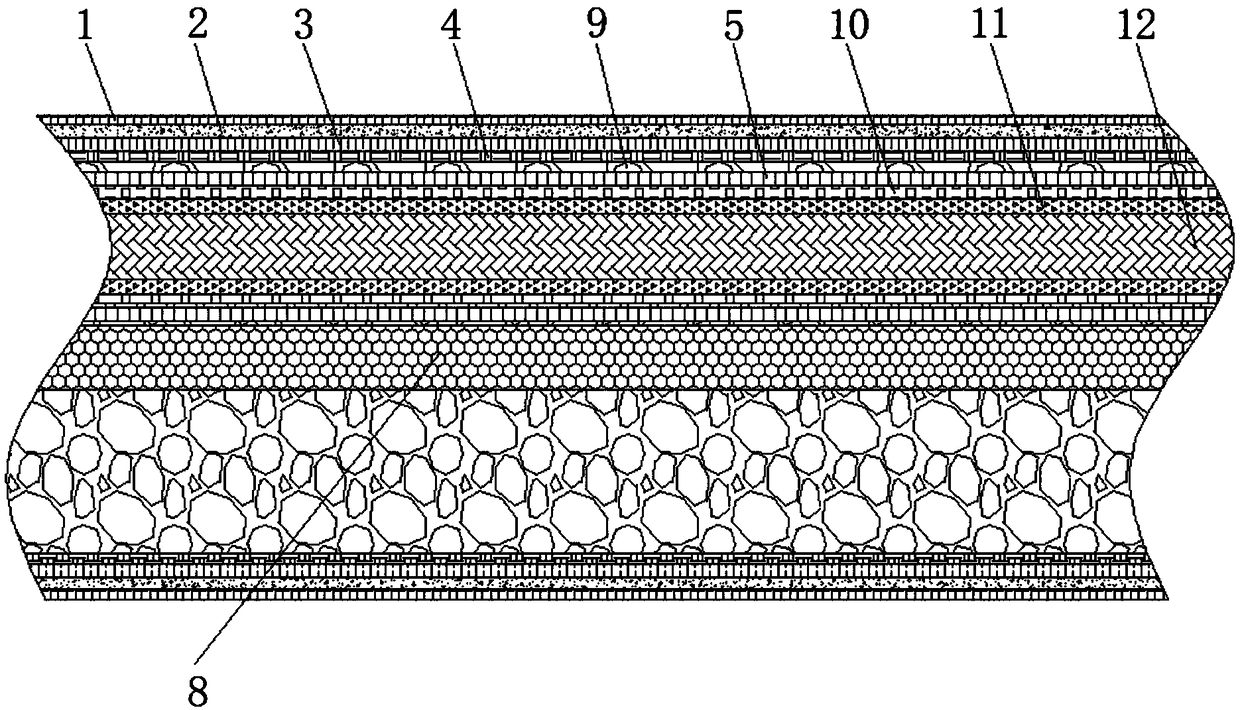

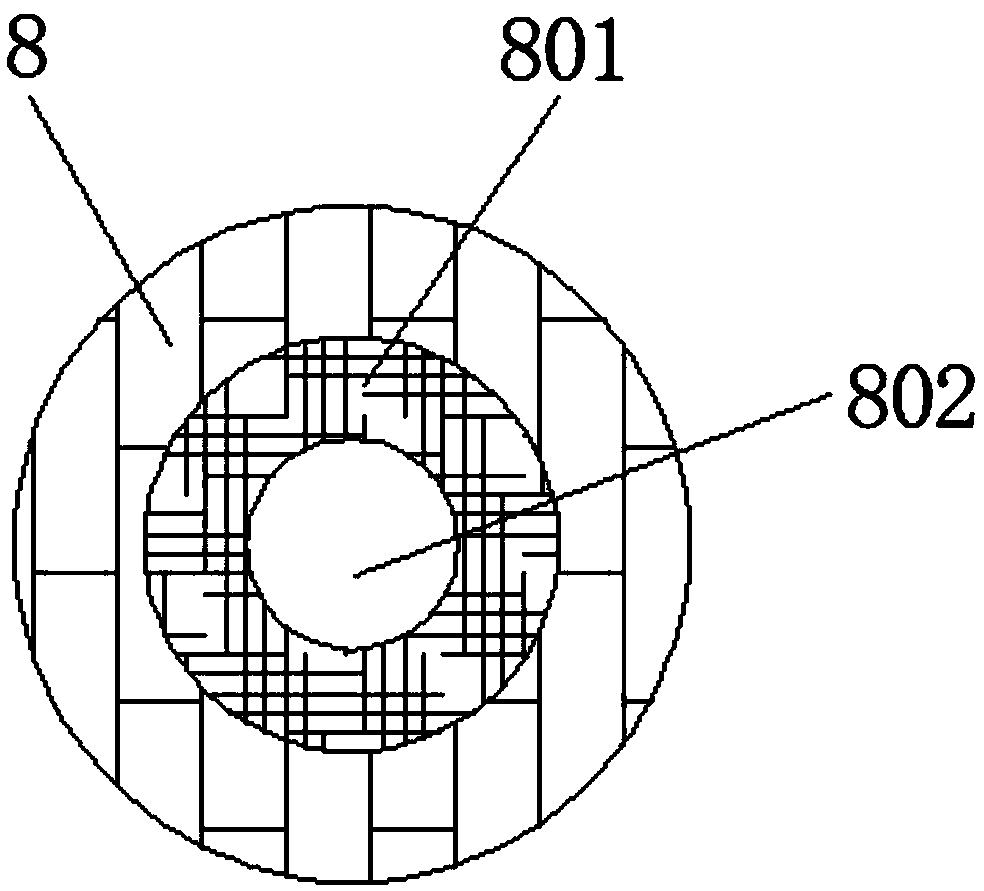

[0018] Such as Figure 1-Figure 3 As shown, a fireproof and wear-resistant copper core armored power cable proposed by the present invention includes a styrene-butadiene rubber layer 1, and the styrene-butadiene rubber belt 1 is made of butadiene and styrene, and the styrene-butadiene rubber 1 has wear resistance, Heat resistance, aging resistance and vulcanization speed are better than natural rubber, and can be used together with natural rubber and various synthetic rubbers. The inner surface of styrene-butadiene rubber layer 1 is fixedly connected with asbestos flame-retardant layer 2, and the thickness of asbestos flame-retardant layer 2 is Between one millimeter and three millimeters, the inner surface of the asbestos flame-retardant layer 2 is fixedly connected with a refractory fiber layer 3, and the inner surface of the refractory fiber layer 3 is fixedly connected with a self-locking steel tape armor layer 4, and the self-locking steel tape armor layer Layer 4 greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com