Micro heat pipe heating radiator and manufacturing method thereof

A technology of radiators and micro heat pipes, which is applied in the field of building heating and heating, can solve the problems of low low-temperature heat radiation capability, slow temperature rise of oil bath, and large water consumption of the system, and achieve high thermal conductivity, fast heat transfer speed, The effect of increasing the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

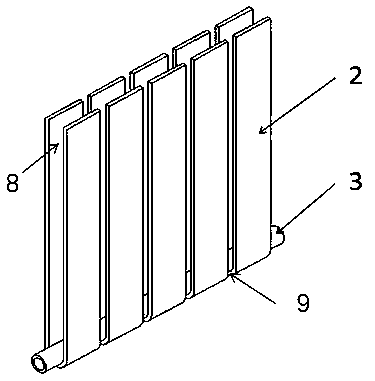

[0035] Embodiment 1: as figure 1 As shown, the superconducting water heating radiator is composed of a plate superconducting heat pipe 2 and a heat source pipe 3. The plate superconducting heat pipe 2 is bent into a U shape and arranged side by side with a certain gap between them. The internal interlayer forms a convection channel 8 The two sides of the lower end of the plate superconducting heat pipe are cold air inlets 9, and the outside of the plate superconducting heat pipe radiates heat from the air, and the structure of the heat sink is extremely simple.

Embodiment 2

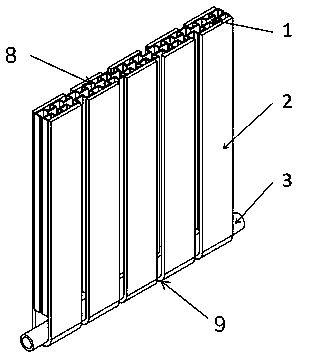

[0036] Embodiment 2: as figure 2 As shown, on the basis of the first embodiment, the superconducting water heating radiator adds fins 1 inside the plate superconducting heat pipe 2, and forms between the fins 1 and between the fins 1 and the plate superconducting heat pipe 2 The convection channel 8, the outside of the plate superconducting heat pipe 2 directly radiates heat with the air, and the lower end of the radiator is provided with a cold air inlet 9, which is beneficial to convection heat dissipation.

Embodiment 3

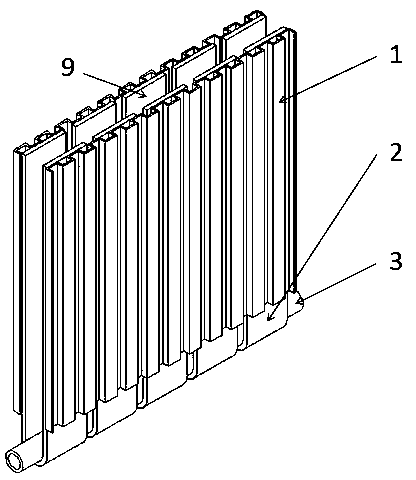

[0037] Embodiment 3: as image 3 As shown, on the basis of the first embodiment, the superconducting water heating radiator adds fins 1 on the outside of the plate superconducting heat pipe 2, and the inner side of the plate superconducting heat pipe 2 forms a convection channel 8, and the plate superconducting heat pipe 2 The outer fins 1 directly radiate and dissipate heat with the air, and the lower end of the radiator is provided with a cold air inlet 9, which is beneficial to convective heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com