A CO for waste heat recovery from high temperature flue gas 2 Cyclic cogeneration system

A technology of cogeneration and high temperature flue gas, which is applied in steam application, machine/engine, combined combustion mitigation, etc. It can solve the problems of insufficient heat source utilization and low overall system efficiency, so as to improve energy utilization efficiency, reduce volume and Occupy area, improve the effect of heat exchange matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments. Obviously, the implementation method described is only one of the preferred implementation methods of the present invention, and the present invention is not limited to the disclosed specific implementation methods, and all simple modifications and changes made to the following examples according to the technical essence of the present invention belong to The protection scope of the present invention.

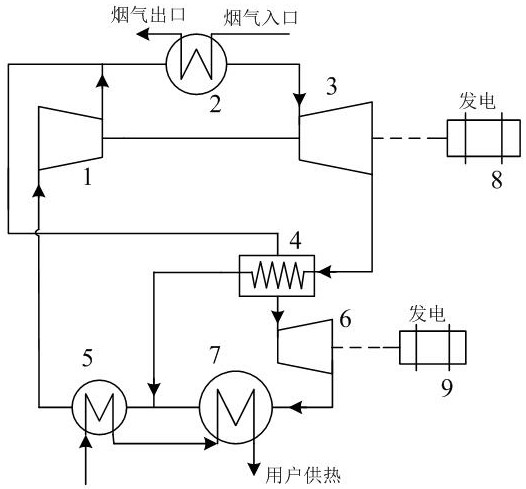

[0019] figure 1 shows the CO used for high temperature flue gas waste heat recovery according to an embodiment of the present invention 2 Schematic diagram of the structure of a cycle cogeneration system. Such as figure 1 As shown, the system mainly includes: compressor 1, supercritical heater 2, first turboexpander 3, second turboexpander 4, condenser 5, gas cooler 6, regenerator 7, second A generator 8, a second generator 9 and a heating circuit.

[0020] The outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com