Construction method of integrated comprehensive treatment of strip mining goaf

A technology of comprehensive treatment and construction method, applied in ground mining, mining equipment, earth-moving drilling, etc., can solve problems such as affecting safety, and achieve the effects of convenient operation, enhanced strength, and reduced bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

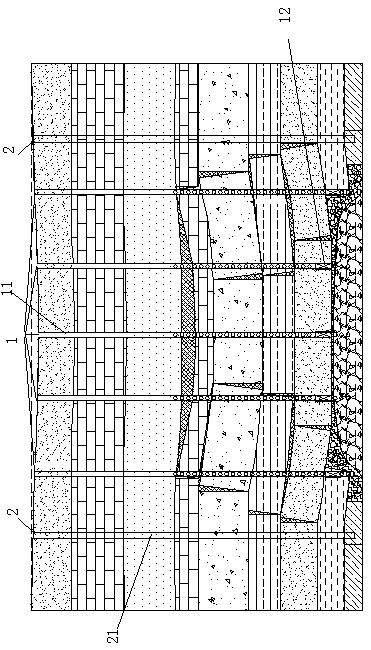

[0029] Embodiment 1: For all roof collapse type goafs, a large amount of collapsed rocks are accumulated in the goafs, such as figure 1 As shown, the specific construction method is as follows:

[0030] 1) Filling with gangue: Set up a number of boreholes 1 from the ground to the goaf, inject gangue through the borehole 1 for filling, mainly from the left and right sides, so that the gangue and the collapsed rock in the goaf fill the goaf ;

[0031] 2) Goaf grouting: After the gangue filling is completed, place a grouting pipe 11 with several grouting holes in the borehole 1, and carry out self-flowing grouting filling in the goaf so that the grout and the goaf The gangue and collapsed rock solidify to form gangue cement;

[0032] 3) Grouting for cracks in the overlying strata and separated layers: After the grouting in the goaf, set grout stoppers 12 at the bottom of several grouting pipes 11 to close the bottom, and inject high pressure grouting into the grouting pipes 11,...

Embodiment 2

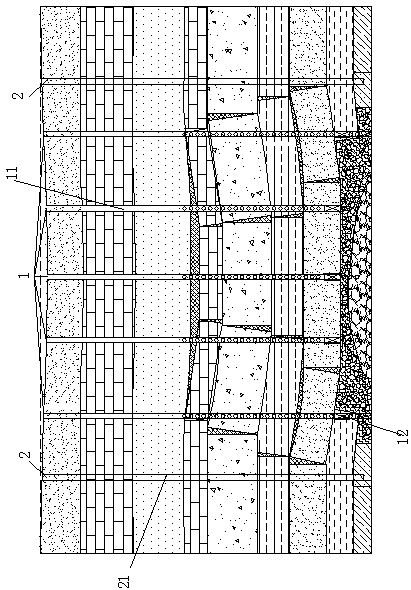

[0034] Example 2: For the partially collapsed goaf of the roof, partially collapsed rocks are accumulated at the bottom of the goaf, such as figure 2 As shown, the specific construction method is as follows:

[0035] 1) Filling with gangue: Set up a number of boreholes 1 from the ground to the goaf, and inject gangue into the goaf through the borehole 1 for filling, so that the gangue and part of the collapsed rock in the goaf fill the goaf;

[0036] 2) Goaf grouting: After the gangue filling is completed, place a grouting pipe 11 with several grouting holes in the borehole 1, and carry out self-flowing grouting filling in the goaf so that the grout and the goaf The gangue and collapsed rock solidify to form gangue cement;

[0037] 3) Grouting for cracks in the overlying strata and separated layers: After the grouting in the goaf, set grout stoppers 12 at the bottom of several grouting pipes 11 to close the bottom, and inject high pressure grouting into the grouting pipes 11...

Embodiment 3

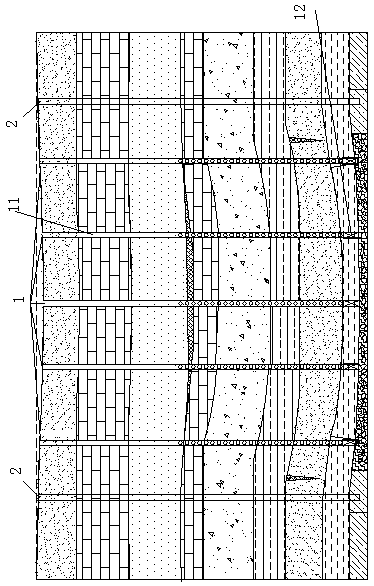

[0039] Example 3: For the roof non-caving type goaf, the roof is bent, there is no collapsed rock at the bottom of the goaf, and the cracks and abscission range of the overlying strata are small, such as image 3 As shown, the specific construction method is as follows:

[0040] 1) Filling with gangue: Set up a number of boreholes 1 from the ground to the goaf, and inject gangue into the goaf through the borehole 1 for filling, so that the gangue fills the goaf;

[0041] 2) Goaf grouting: After the gangue filling is completed, place a grouting pipe 11 with several grouting holes in the borehole 1, and carry out self-flowing grouting filling in the goaf so that the grout and the goaf The gangue and collapsed rock solidify to form gangue cement;

[0042] 3) Grouting for cracks in the overlying strata and separated layers: After the grouting in the goaf, set grout stoppers 12 at the bottom of several grouting pipes 11 to close the bottom, and inject high pressure grouting into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com