SAGD production fluid treatment method and device based on two-stage separation

A treatment method and technology for produced fluids, which are applied in the treatment of hydrocarbon oil, dehydration/demulsification by chemical methods, and only multi-stage serial refining process treatment, etc., can solve the problems that the produced fluid treatment process cannot meet the treatment requirements, etc. Achieve the effect of improving crude oil recovery rate, guaranteeing treatment effect and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

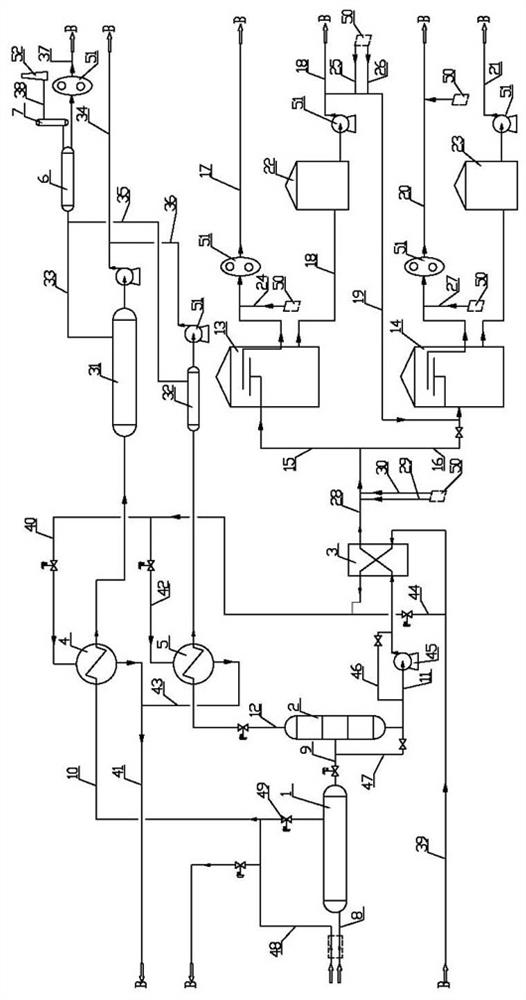

[0027] Embodiment 1: The SAGD production liquid processing method based on the two-stage separation is carried out as follows: the SAGD production liquid is subjected to gas-liquid separation under pressure conditions to obtain the first gas phase and the first liquid phase, the first After the liquid phase is separated by flash evaporation, the second liquid phase and the second gas phase are obtained, and the second liquid phase is subjected to heat exchange cooling and sedimentation to obtain crude oil and purified water, and the first gas phase and the second gas phase are heat exchanged and cooled to obtain steam Condensed water and the third gas phase, the third gas phase is subjected to gas-liquid separation to obtain the third liquid phase and the gas phase to be desulfurized, and the desulfurized gas phase is obtained after desulfurization of the gas phase to be desulfurized.

[0028] The SAGD production fluid treatment method based on the two-stage separation describe...

Embodiment 2

[0033] Embodiment 2: As the optimization of the above-mentioned embodiment, the SAGD production fluid is under the condition of a pressure of 0.6MPa to 0.8MPa, and the gas-liquid separation is carried out to obtain the first gas phase and the first liquid phase, and the first liquid phase is obtained at a pressure of 0.05 After flash separation under the condition of MPa to 0.1MPa, the second liquid phase and the second gas phase are obtained; or / and, the second liquid phase after heat exchange and cooling is added to the second liquid phase after heat exchange and cooling before settling Water purifier and coagulant aid, the dosage of water purifier is 200mg / L to 600mg / L, and the dosage of coagulant aid is 2mg / L to 3mg / L.

[0034] The water purifying agent and coagulation aid used in the present invention are respectively existing known water purifying agents and coagulation aids, and the water purifying agent can adopt existing known amine water purifying agents. As a coagul...

Embodiment 3

[0037] Example 3: As an optimization of the above-mentioned Example 2, after the second liquid phase undergoes heat exchange and cooling, it first settles for the first time, and after the first settling, crude oil and primary effluent are obtained, and the primary effluent is settled again to obtain crude oil and purification out of water.

[0038] The method described in Example 3 is applicable to the incoming liquid from a single well (SAGD produced liquid) with relatively high steam content in the middle and early stage of the circulation preheating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com