The method of speeding up the speed of konjac gel

A technology of gelation speed and konjac, which is applied in the field of konjac, can solve the problems of uneven texture of gel products, uneven local heating, long heating time, etc., and achieve shortened gelation time, tight texture, and enhanced water retention performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for accelerating konjac gel speed may further comprise the steps:

[0030] 1) By weight, take 100 parts of ordinary konjac flour, add 5 parts of chitosan for mixing, and then add it to 300 parts of normal temperature water for sol for 40 minutes;

[0031] 2) Take 5 parts of calcium oxide and 1 part of calcium dihydrogen phosphate and mix them evenly, then add them into the sol, stir in vacuum for 2 minutes; heat with steam for 15 minutes, and control the temperature at 90-95°C to get konjac instant gel.

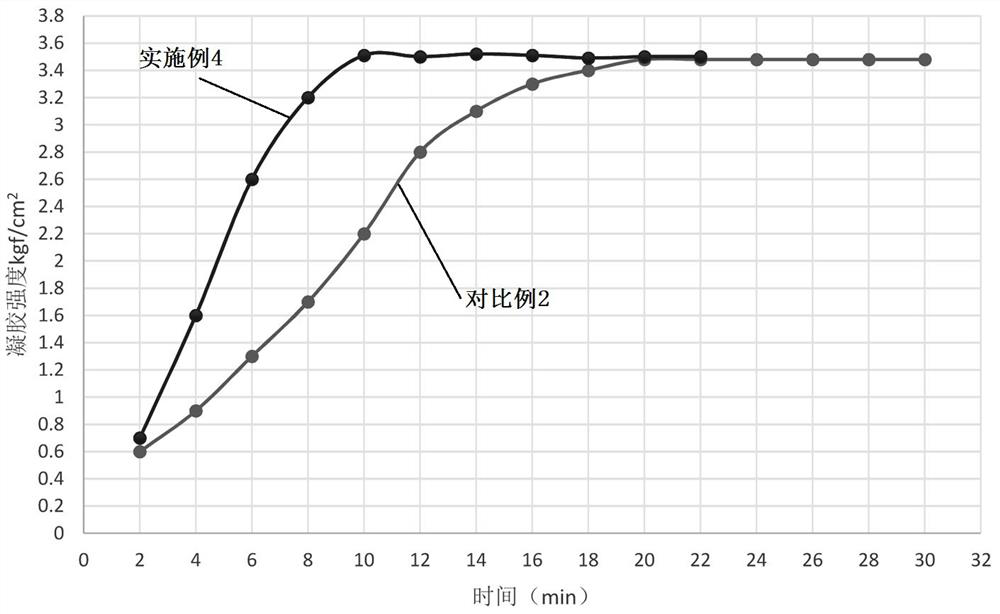

[0032] The konjaku flour gel strength and time relationship figure after comparative example 1 and embodiment 1 are processed are as follows figure 1 As shown, the gel strength of Example 1 can be stabilized at 15 minutes, while in Comparative Example 1, it can be kept stable at 32 minutes, and the gel strength of Example 1 is slightly greater than that of the gel in Comparative Example 1 strength.

Embodiment 2

[0034] 1) Mix 120 parts of instant konjac flour, 4 parts of crosslinking agent chitosan and carboxymethyl starch according to the weight ratio to obtain a mixed material;

[0035] 2) Add the mixed material obtained in step 1) into water 30 times the mass of konjac flour, and dissolve for 15 minutes;

[0036] 3) Take 8 parts of gelling agent by weight, including 6 parts of calcium oxide and 2 parts of calcium chloride, mix with 1 part of catalyst calcium phosphate to obtain a mixed material, and add the mixed material to the sol obtained in step 2) , stirred under vacuum for 1 min to obtain a jelly;

[0037] 4) Quickly heat the jelly obtained in step 3) with steam for 10 minutes; konjac instant gel can be obtained.

Embodiment 3

[0039] 1) Mix 110 parts of purified konjac flour and 5 parts of crosslinking agent propylene oxide by weight to obtain a mixed material;

[0040] 2) Add the mixed material obtained in step 1) into water 30 times the mass of konjac flour, and sol for 30 minutes;

[0041] 3) Mix 7 parts of gelling calcium oxide and 2 parts of catalyst calcium phosphate according to the weight ratio to obtain a mixed material, add the mixed material to the sol obtained in step 2), and stir in vacuum for 2 minutes to obtain a jelly;

[0042] 4) Quickly heat the jelly obtained in step 3) with steam for 13 minutes; konjac instant gel can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com