Combined anode carbon block slotting equipment

A technology of anode carbon block and slotting equipment, which is applied in stone processing equipment, metal processing equipment, abrasives, etc., can solve the problems of high scrap rate of saw blades, unfavorable production and use, and high processing noise, so as to save workshop space and electric energy , the effect of low equipment noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

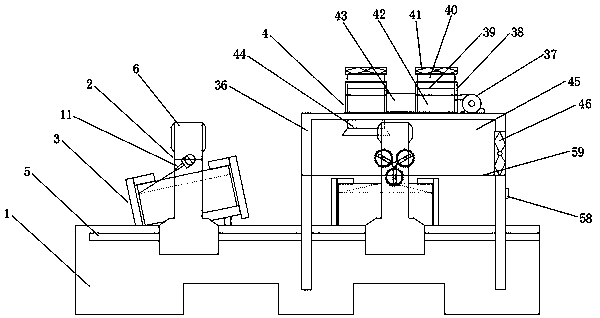

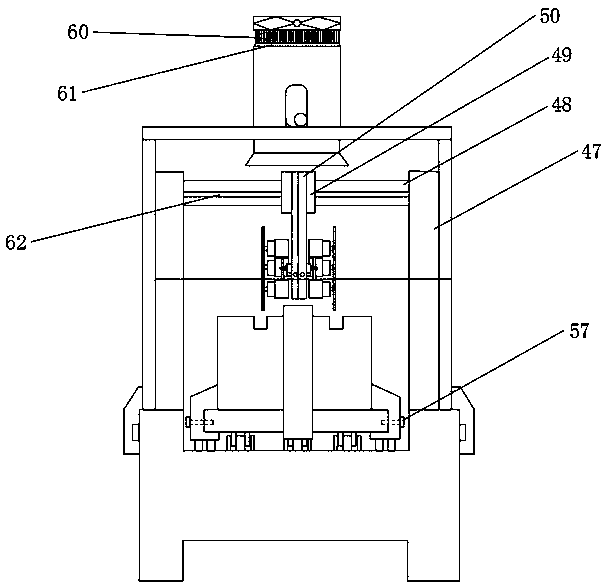

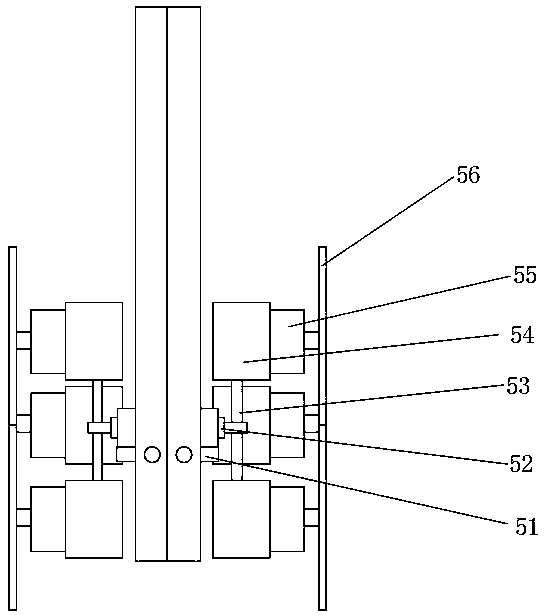

[0034] As shown in the drawings of the description, a combined anode carbon block slotting equipment includes a machine base 1, a water cutting device 2, an automatic fixing device 3, a mechanical cutting device 4 and a control system. Both sides of the base 1 are provided with side slides 5, and the middle part is provided with an inner slide 13; the water cutting device 2 and the mechanical cutting device 4 are all slidably connected with the side slides 5; the automatic fixing device 3 is connected with the inner slide. The slideway 13 is slidingly connected; the water cutting device 2 is provided with two groups of water jet nozzles 11; the water jet nozzles 11 are connected with the universal joint pipe 10; the bottom of the machine base 1 is provided with two groups of material deflection hydraulic cylinders 12. The mechanical cutting device 4 is provided with a soundproof cover 36; the soundproof cover 36 is shrouded on the mechanical cutting device 4, and the side is pr...

Embodiment 2

[0039]A combined anode carbon block slotting equipment includes a machine base 1, a water cutting device 2, an automatic fixing device 3, a mechanical cutting device 4 and a control system. Both sides of the base 1 are provided with side slides 5, and the middle part is provided with an inner slide 13; the water cutting device 2 and the mechanical cutting device 4 are all slidably connected with the side slides 5; the automatic fixing device 3 is connected with the inner slide. The slideway 13 is slidingly connected; the water cutting device 2 is provided with two groups of water jet nozzles 11; the water jet nozzles 11 are connected with the universal joint pipe 10; the bottom of the machine base 1 is provided with two groups of material deflection hydraulic cylinders 12. The mechanical cutting device 4 is provided with a soundproof cover 36; the soundproof cover 36 is shrouded on the mechanical cutting device 4, and the side is provided with a door handle 58; a partition 59 i...

Embodiment 3

[0045] A combined anode carbon block slotting equipment includes a machine base 1, a water cutting device 2, an automatic fixing device 3, a mechanical cutting device 4 and a control system. Both sides of the base 1 are provided with side slides 5, and the middle part is provided with an inner slide 13; the water cutting device 2 and the mechanical cutting device 4 are all slidably connected with the side slides 5; the automatic fixing device 3 is connected with the inner slide. The slideway 13 is slidingly connected; the water cutting device 2 is provided with two groups of water jet nozzles 11; the water jet nozzles 11 are connected with the universal joint pipe 10; the bottom of the machine base 1 is provided with two groups of material deflection hydraulic cylinders 12. The mechanical cutting device 4 is provided with a soundproof cover 36; the soundproof cover 36 is shrouded on the mechanical cutting device 4, and the side is provided with a door handle 58; a partition 59 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com